Device and system for the intermediate storage of thermal energy

a technology of thermal energy storage and intermediate storage, which is applied in the direction of storage heaters, space heating and ventilation details, domestic heating details, etc., can solve the problems of affecting the economic benefits of such a heat accumulator, requiring a relative long time interval,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

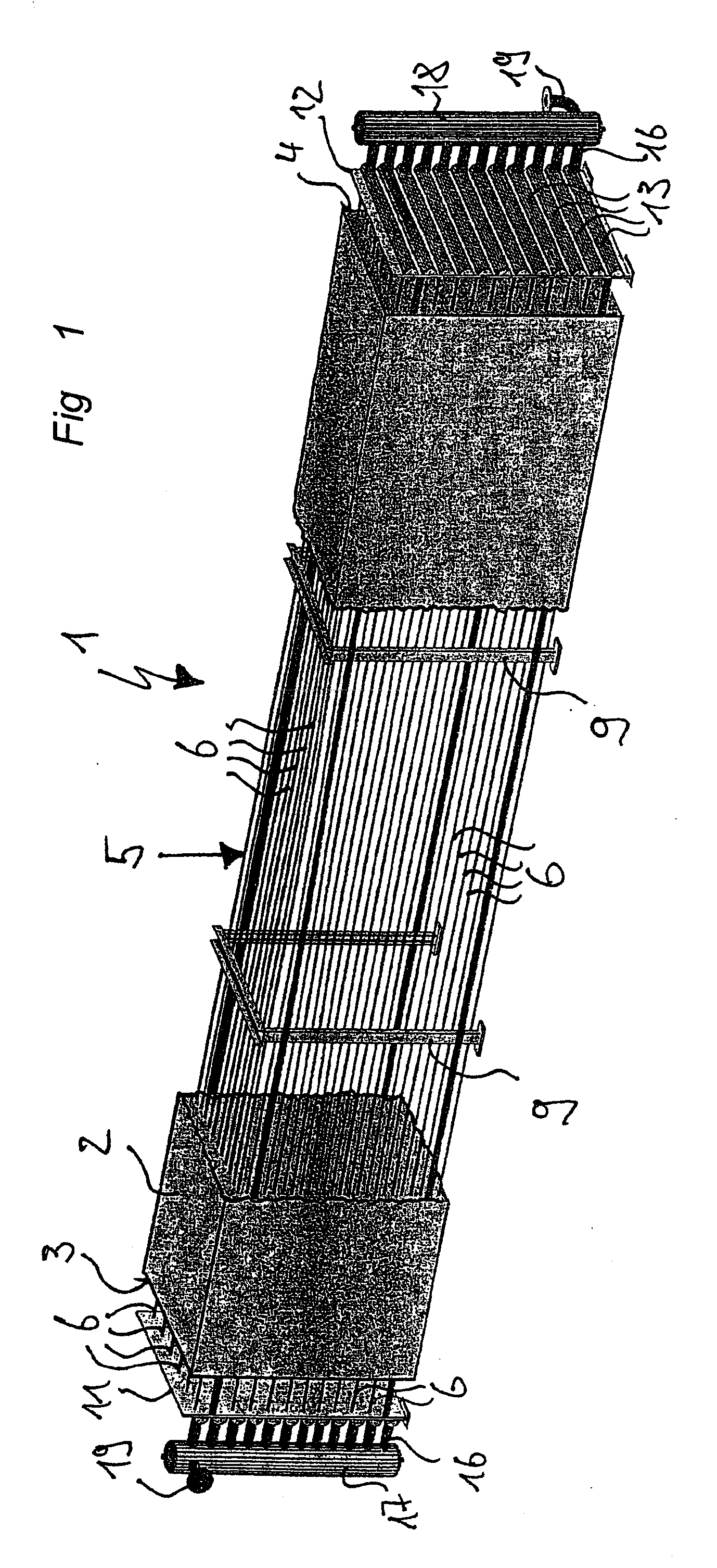

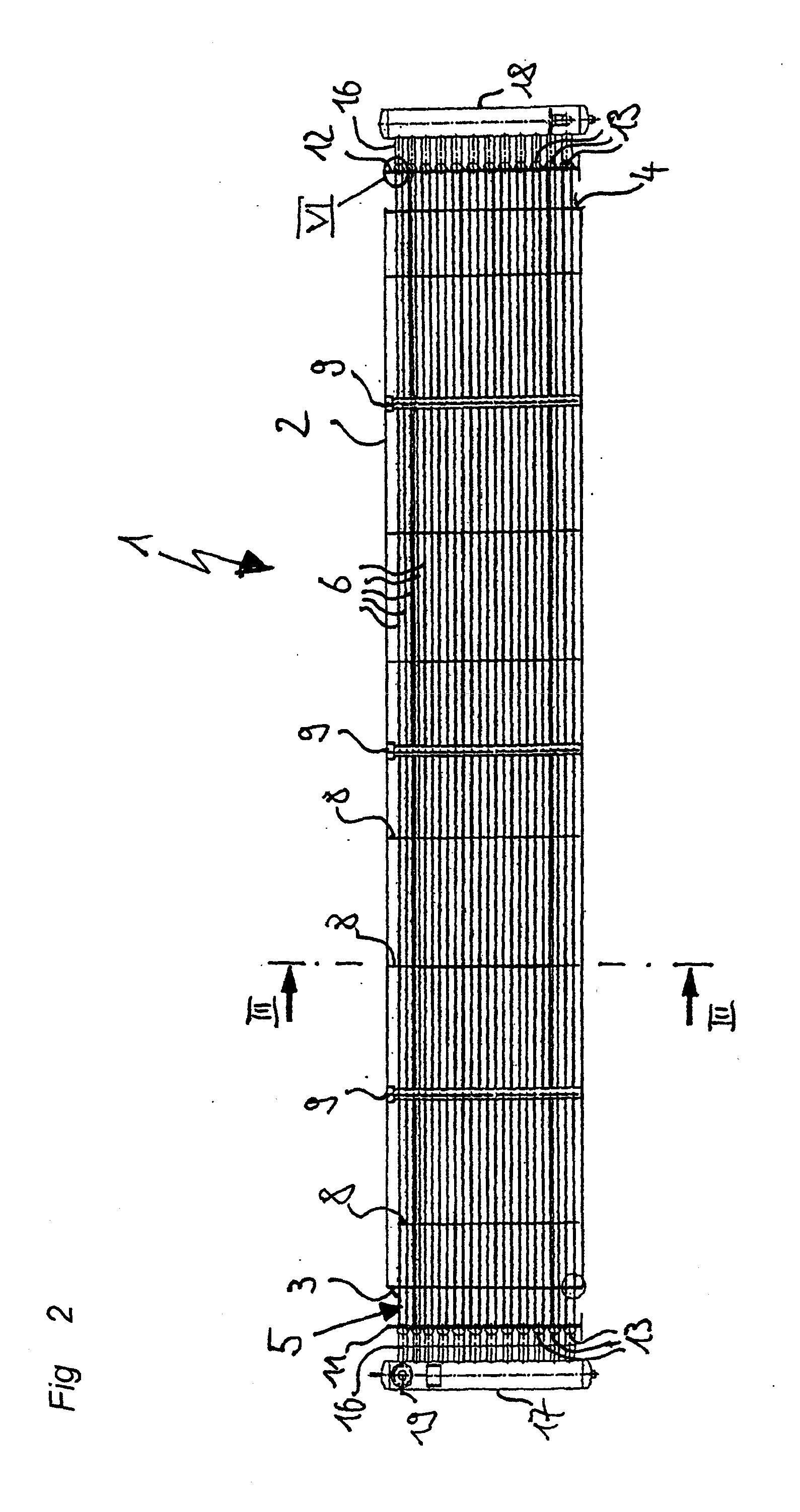

first embodiment

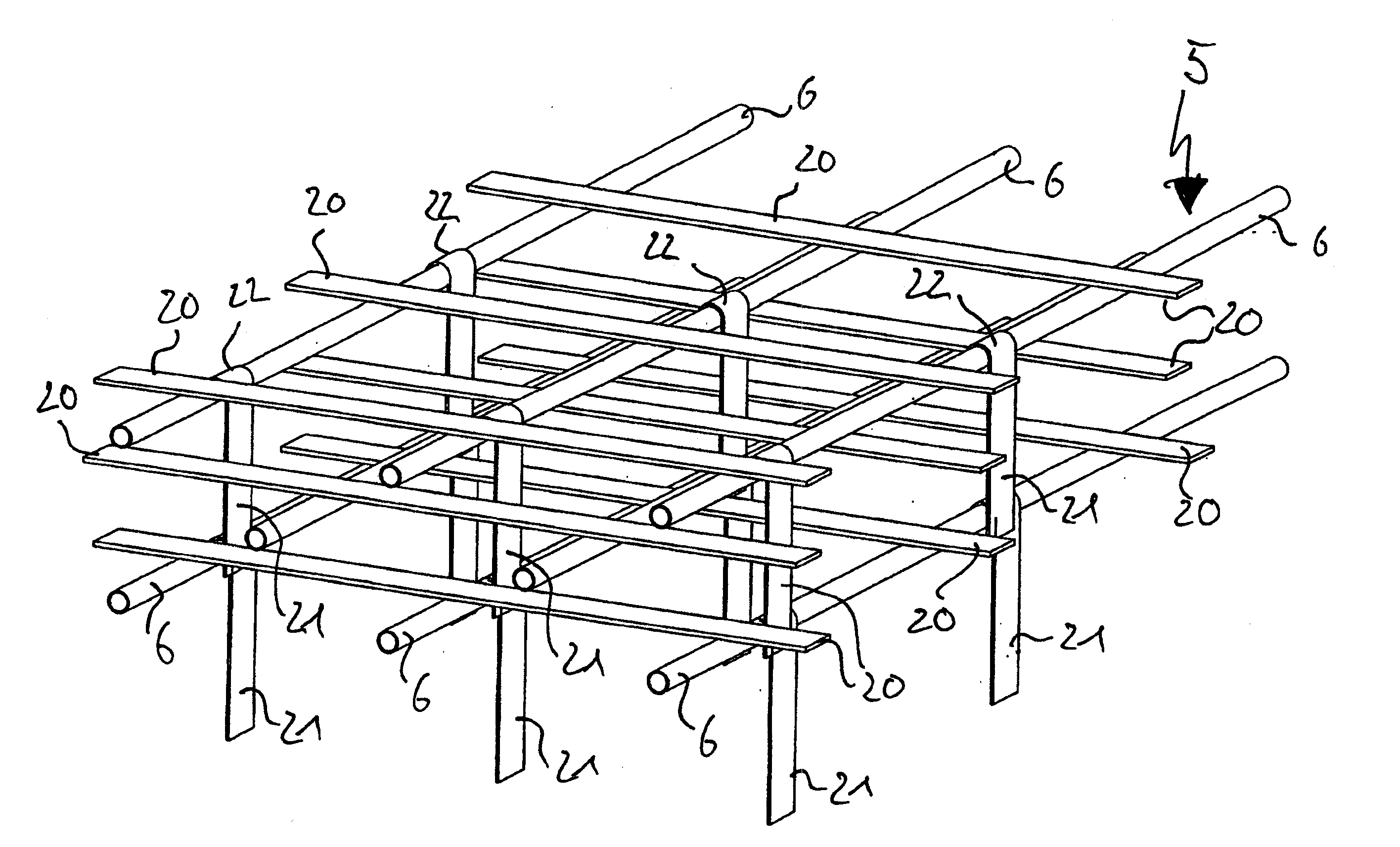

[0041]FIG. 4 shows heat conducting elements according to the invention in an oblique view of a partial detail of pipe system 5, whereby for a clearer illustration solid storage medium 2 itself is not shown. Seen are individual pipes 6 in horizontally stacked levels and running axis-parallel to one another, said pipes which are arranged from one level to another with a lateral offset in the height of half the mutual lateral distance, so that the distance between two individual pipes 6 is uniform at each place in solid storage medium 2. In addition, individual pipes 6 are mechanically decoupled from solid storage medium 2, for example, by sheathing with a graphite film (not shown).

[0042]Whereas primarily a heat distribution in solid storage medium 2 occurs in the axial direction in individual pipes 6 due to the energy transfer medium flowing therein, horizontal heat conducting elements 20 and vertical heat conducting elements 21 are provided for lateral distribution of the thermal ene...

second embodiment

[0047]FIG. 5 shows a partial detail of a heat accumulator 1 of the invention. In this embodiment, solid storage medium 2 has prefabricated elements 23, which are placed one on top of another in horizontal layers 24 in a modular manner, whereby individual pipes 6 of pipe system 5 run in the horizontal butt joints of adjacent layers 24.

[0048]As already mentioned, only the functional principle of heat accumulator 1 is to be clarified with the type of presentation selected in FIG. 5, which is why only a small partial detail of heat accumulator 1 is shown. In reality, prefabricated elements 23, depending on the size of solid storage medium 2, extend over the entire width and / or length of solid storage medium 2 or only over a part thereof when a number of prefabricated elements 23 are strung together. The thickness of prefabricated elements 23 corresponds to the vertical distance of individual pipes 6 of pipe system 5.

[0049]Groove-shaped recesses 25 are formed in the top side of prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com