Systems and methods for improving the efficiency of a combined cycle power plant

a technology of combined cycle power plant and efficiency improvement, which is applied in the direction of machines/engines, mechanical equipment, turbine/propulsion fuel heating, etc., can solve the problems of not being able to meet the demand in the energy market, not always feasible base load operations, and gas turbine operating at part load may not maintain emissions compliance, etc., to improve the efficiency of the power generation facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

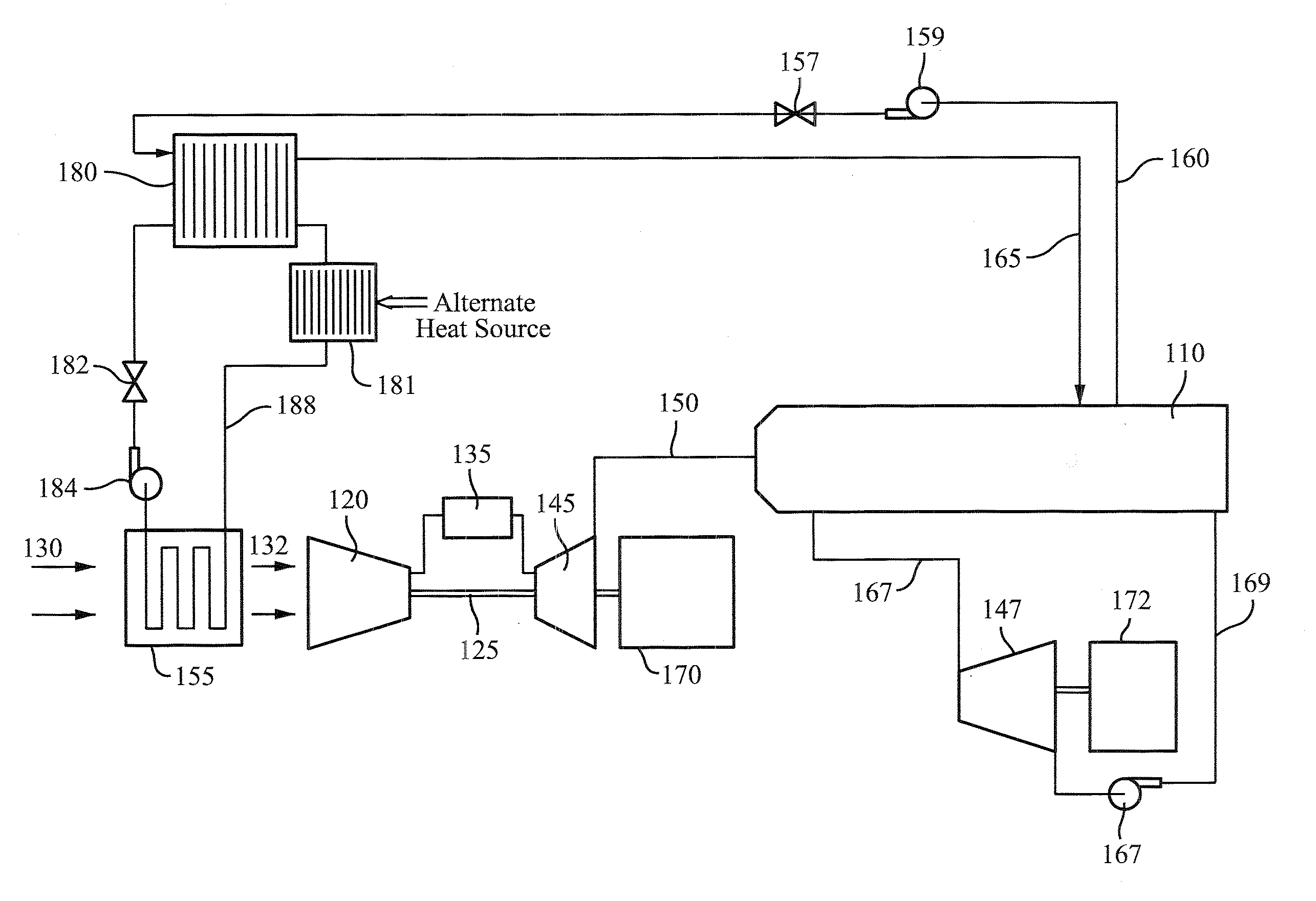

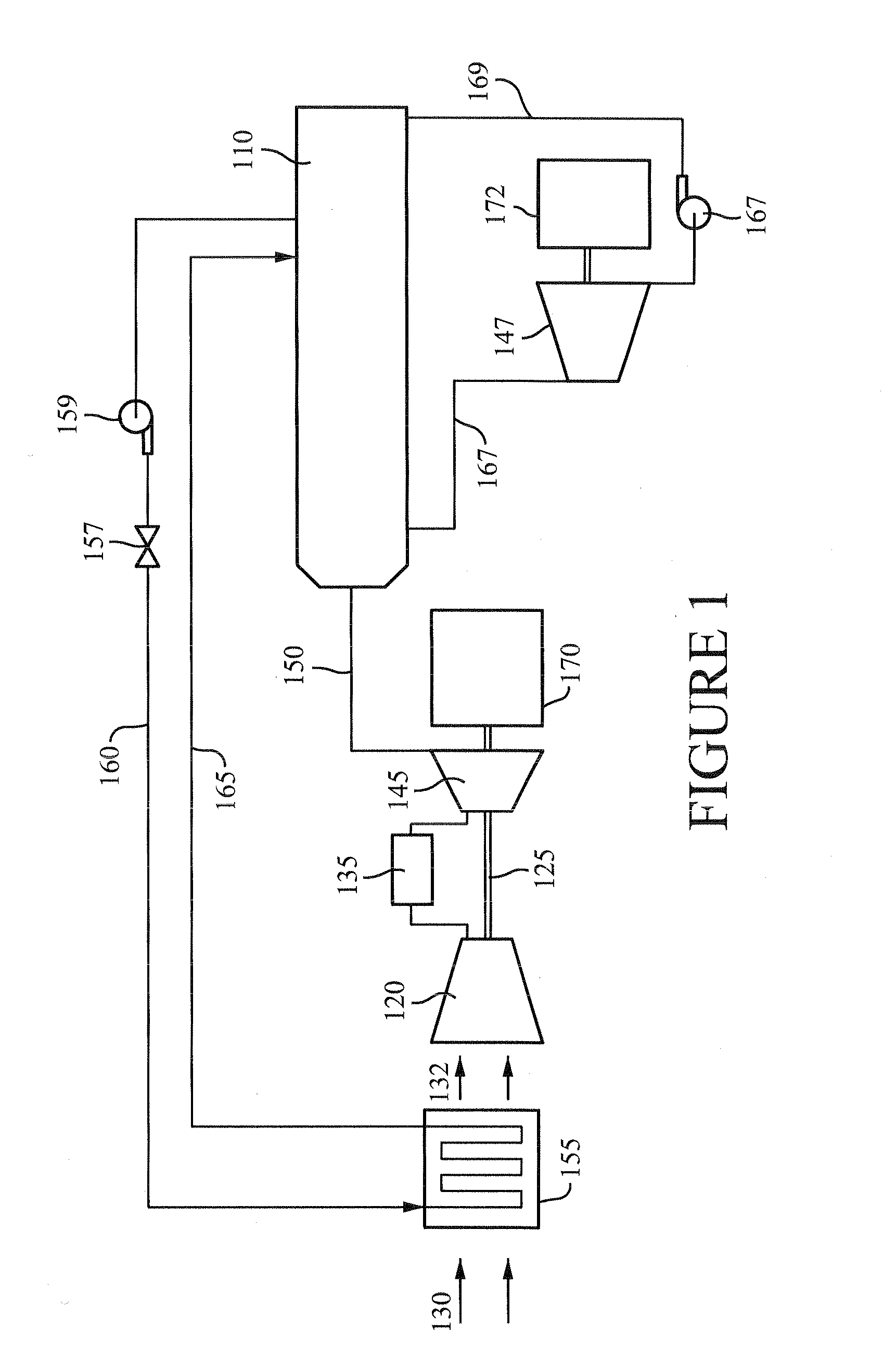

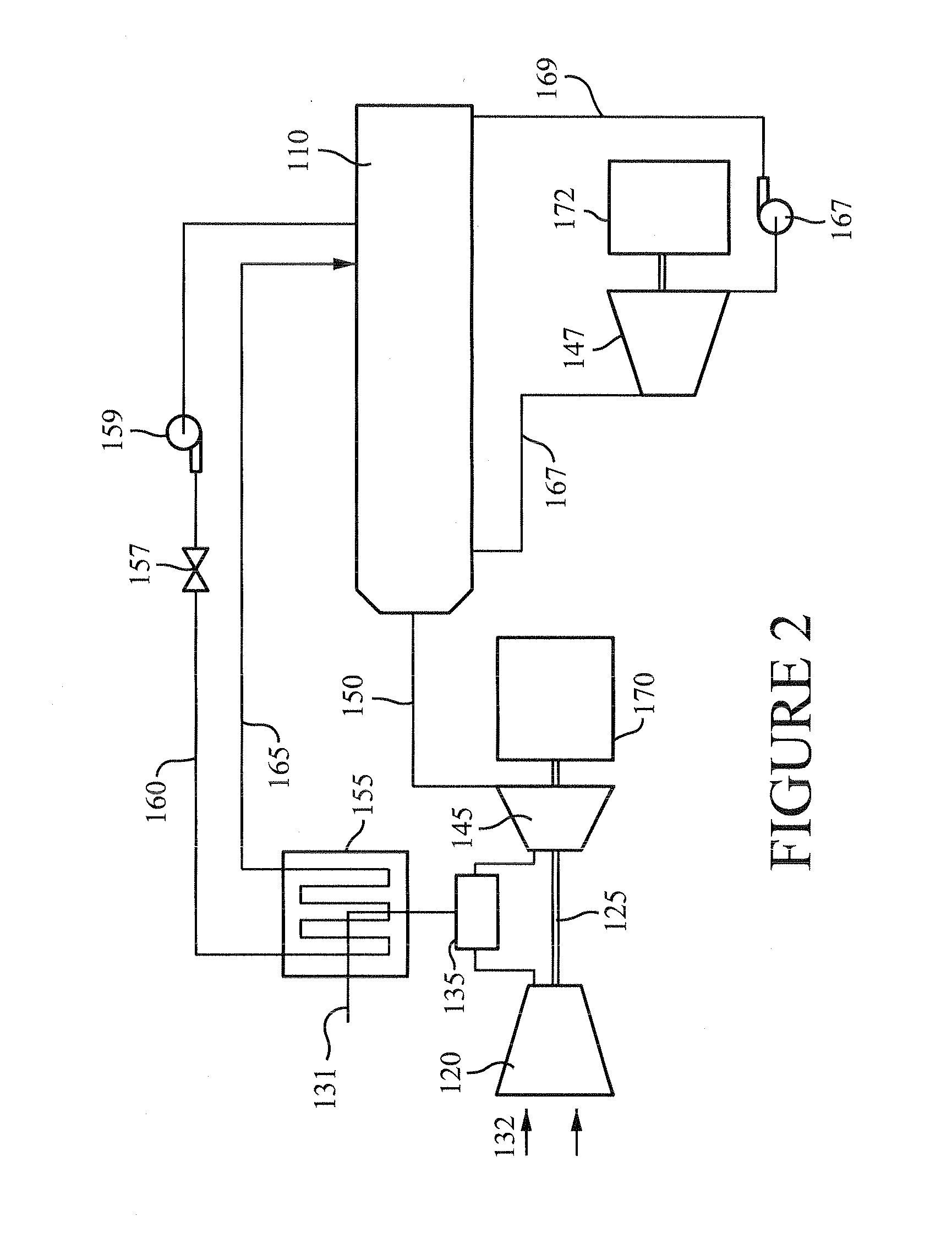

[0016]The following detailed description of preferred embodiments refers to the accompanying drawings, which illustrate specific embodiments of the invention. Other embodiments having different structures and operations do not depart from the scope of the present invention.

[0017]The present invention may be applied to a wide variety of turbomachines including, but not limited to, gas turbines, aero-derivative combustion turbines, and the like. An embodiment of the present invention takes the form of an application and process that extracts heat energy from a source other than the turbomachine and that uses that heat energy to increase the efficiency of the turbomachine when the turbomachine is operating at part load conditions. The extracted heat energy could be used to heat the air entering a turbomachine, to heat fuel that is burned in the turbomachine, or for other purposes. An embodiment of the present invention has the technical effect of improving the efficiency of a power gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com