Sealed body, method for manufacturing sealed body, light-emitting device, and method for manufacturing light-emitting device

a technology of sealing body and sealing plate, which is applied in the direction of thermoelectric devices, transportation and packaging, other domestic articles, etc., can solve the problems of large size of the apparatus, large influence on productivity, and long time to reach the desired baking temperature, etc., and achieve high productivity and high reliability. , the effect of high-quality sealing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0048]In this embodiment, a method for manufacturing a sealed body, according to an embodiment of the present invention, will be described with reference to FIGS. 1A to 1D, FIGS. 2A and 2B, and FIGS. 3A to 3E.

example 1

MANUFACTURING METHOD EXAMPLE 1

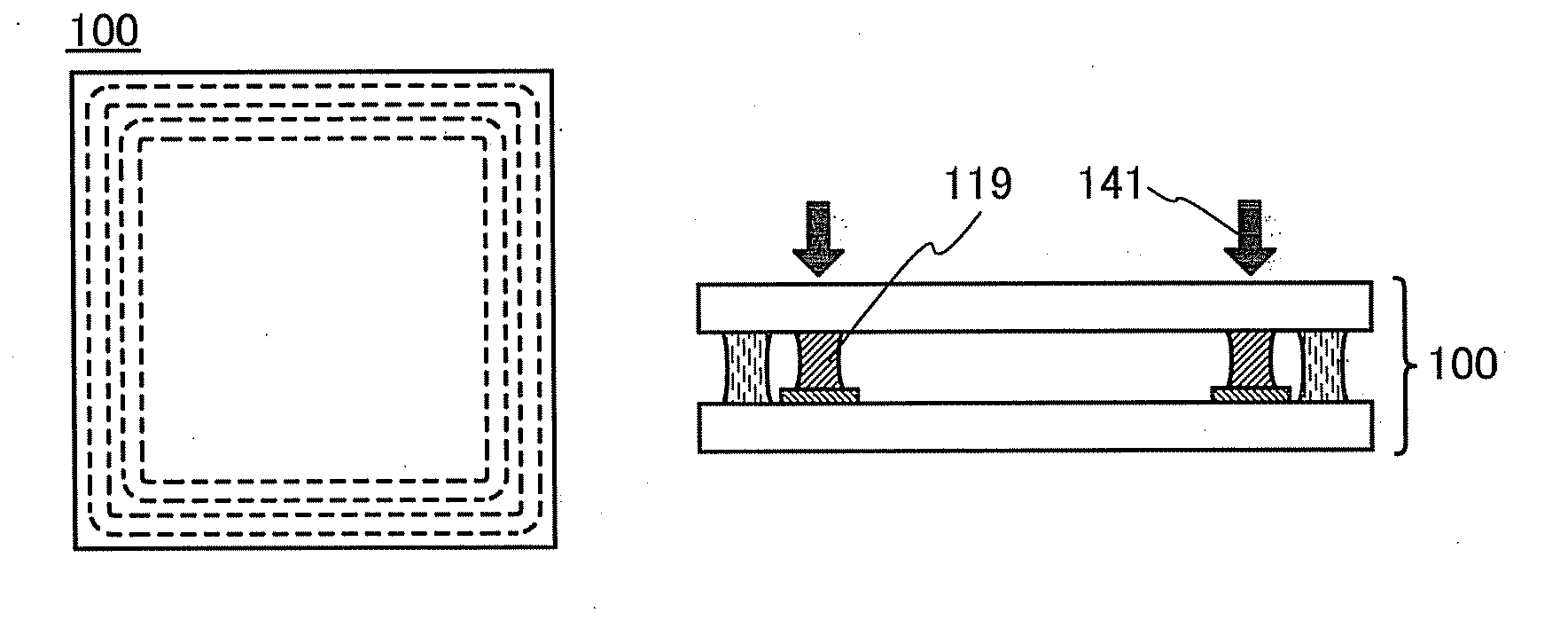

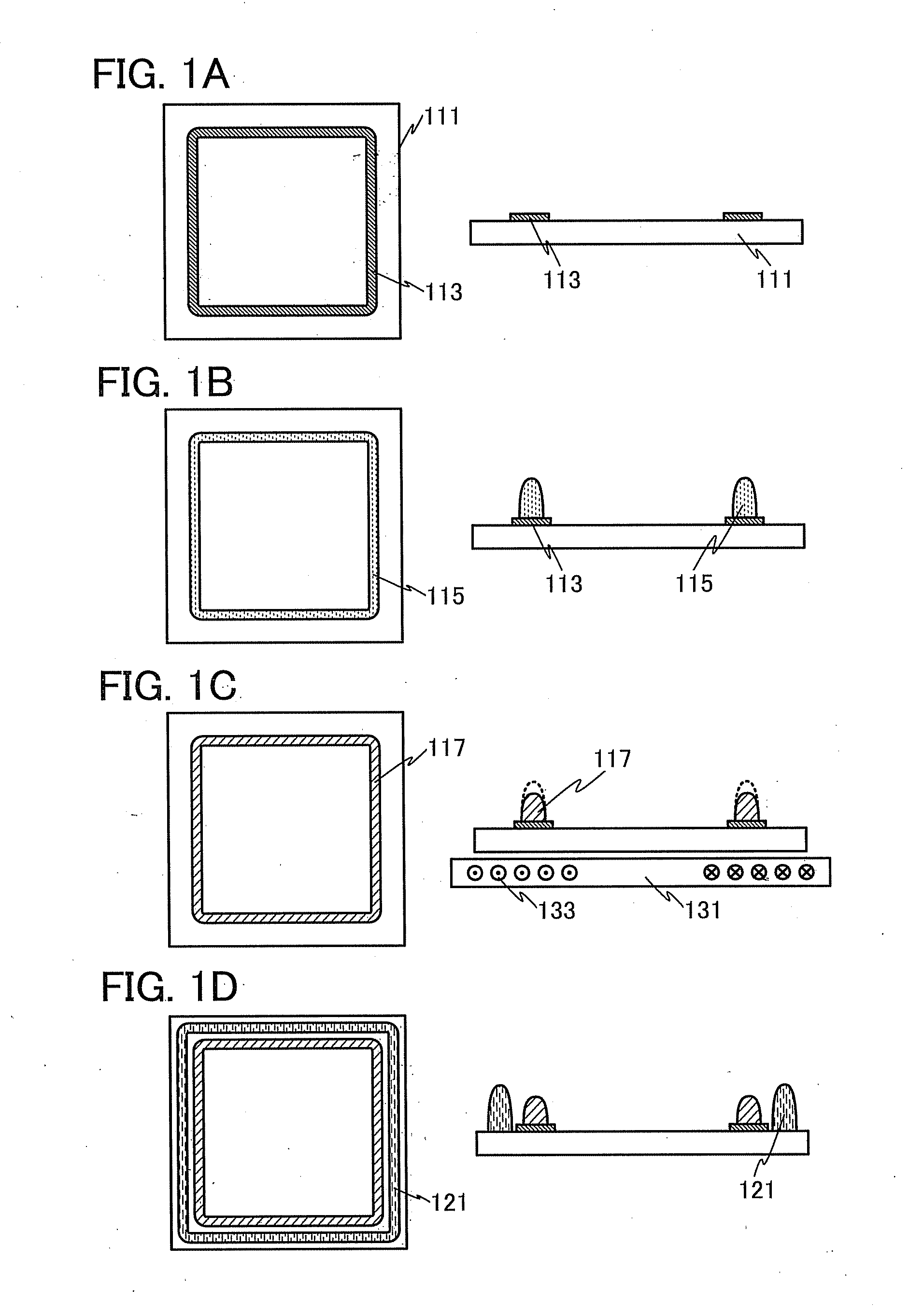

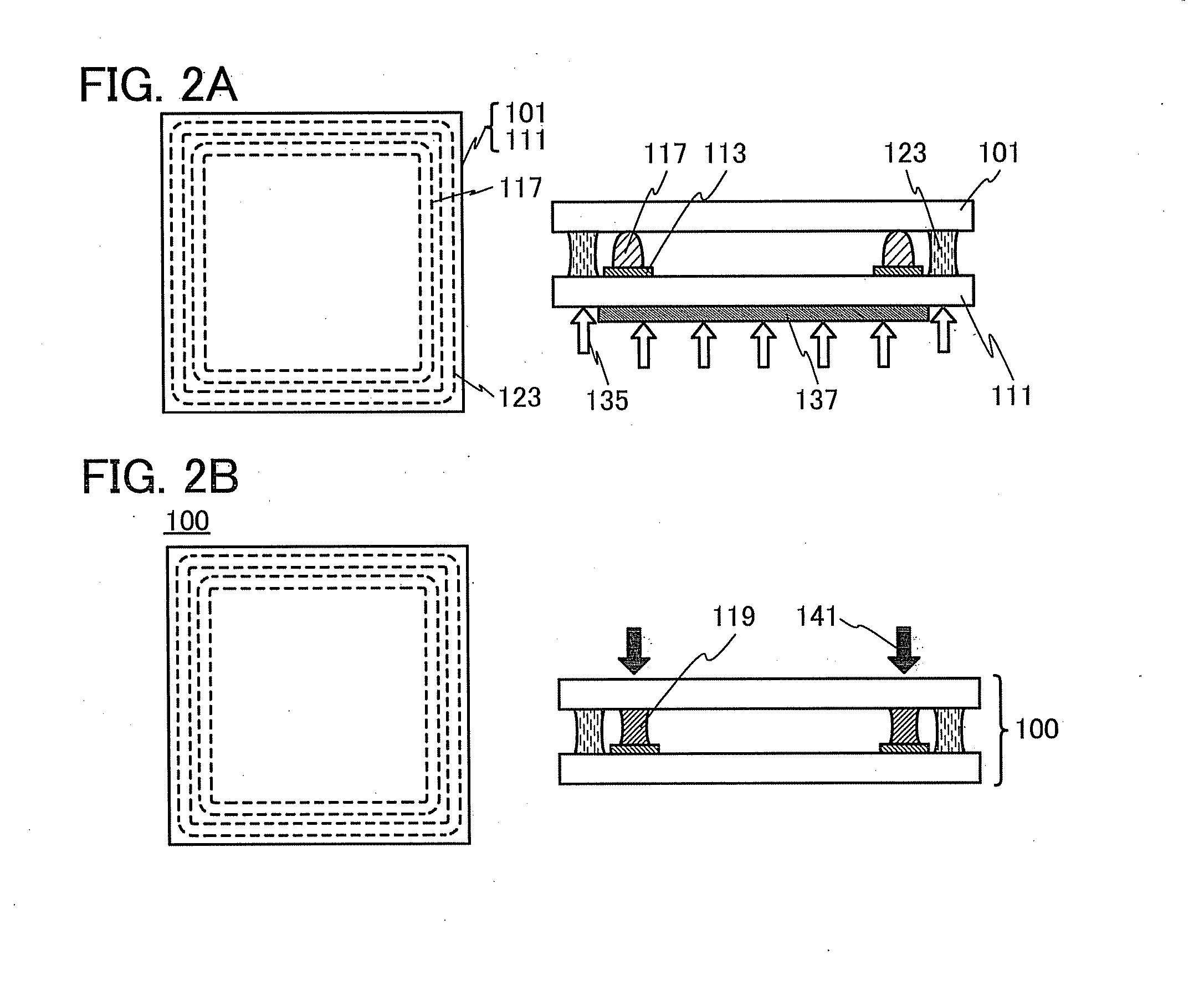

[0049]FIGS. 1A to 1D and FIGS. 2A and 2B illustrate a method for manufacturing a sealed body described in this manufacturing method example. In each of FIGS. 1A to 1D and FIGS. 2A and 2B, a schematic top view and a corresponding schematic cross-sectional view are illustrated.

[0050]First, a heat generation layer 113 is formed over a first substrate 111 (see FIG. 1A). The heat generation layer 113 includes a conductive material which can generate heat in later induction heating treatment. The heat generation layer 113 includes a material which generates heat enough to heat a frit paste 115 formed over the heat generation layer 113 so that a binder in the frit paste 115 is removed and a frit material in the frit paste 115 is melted. Note that a material which can withstand at least temperature at which the binder contained in the frit paste 115 is removed is used for the heat generation layer 113.

[0051]As a material which can generate heat by induction hea...

example 2

MANUFACTURING METHOD EXAMPLE 2

[0079]When a conductive material is included in a frit paste, the frit paste itself can be baked by an induction heating method without the heat generation layer 113. A method for manufacturing a sealed body with the use of a frit paste including a conductive material will be described below with reference to FIGS. 3A to 3E. Note that description of the portions described in Manufacturing Method Example 1 is omitted or is simply given.

[0080]FIGS. 3A to 3E illustrate a method for manufacturing a sealed body described in this manufacturing method example. Note that each of FIGS. 3A to 3E illustrates a schematic cross-sectional view of a step.

[0081]First, a frit paste 155 is formed over the first substrate 111 (see FIG. 3A).

[0082]The frit paste 115 to which a conductive material is added is used as the frit paste 155. Any of the materials which can be used for the heat generation layer 113 can be used as the conductive material. The conductive material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com