Polarizing lens made of aromatic polycarbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

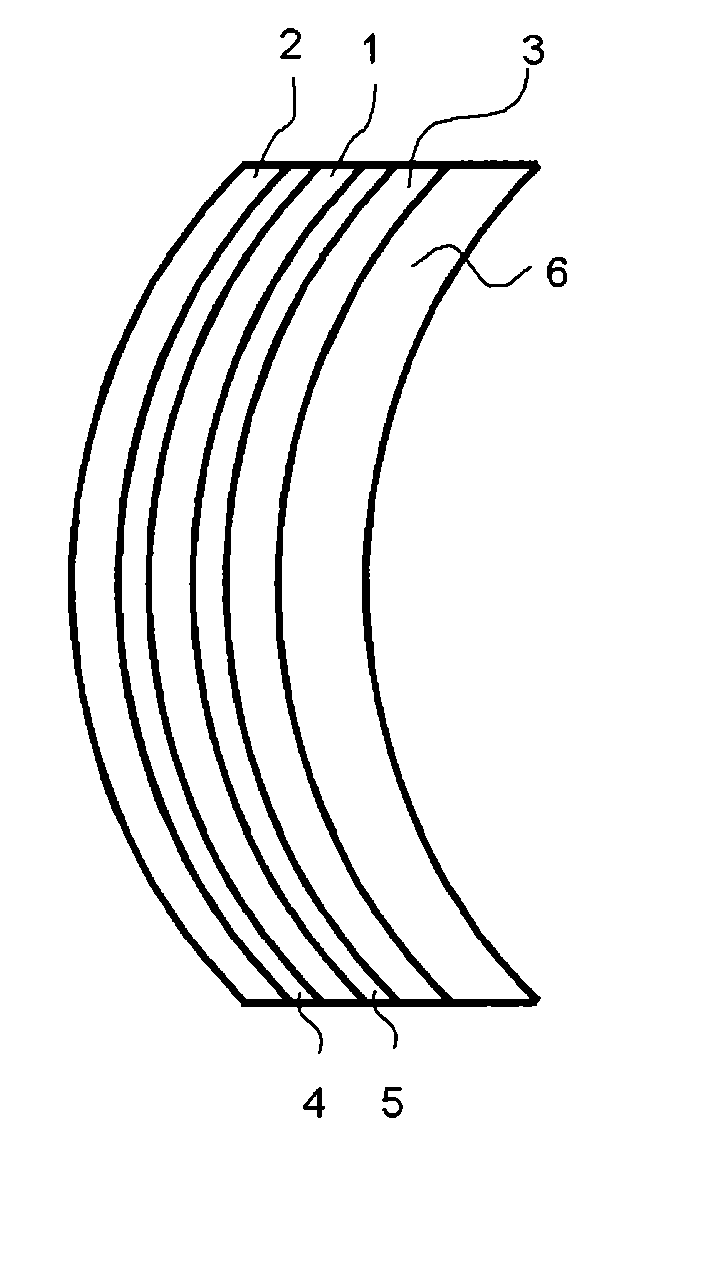

[0071](a) Stretched Polycarbonate Polarizing Sheet

[0072]As a stretched polycarbonate polarizing sheet for use in an aromatic polycarbonate polarizing lens, Iupilon Pola sheet with a thickness of 0.6 mm (made by Mitsubishi Gas Chemical Company) was used. The stretched polycarbonate polarizing sheet uses an aromatic polycarbonate sheet with a thickness of 0.3 mm, a retardation value of 5500 nm, and a glass transition point of 150° C. as a protective layer on both surfaces of the polarizing film, and is a polarizing sheet less likely to have a colored interference pattern occur in bending processing.

[0073](b) Aromatic Polycarbonate Polarizing Lens

[0074]The polarizing sheet of (a) was punched out with a complete round die with a diameter of 79.5 mm, the width in the vertical direction was cut into 55 mm, and bending processing was performed so as to correspond to the spheric surface (curvature radius 66.81 mm, base curve 7.932) of the mold used in injection molding, using a mold with th...

example 2

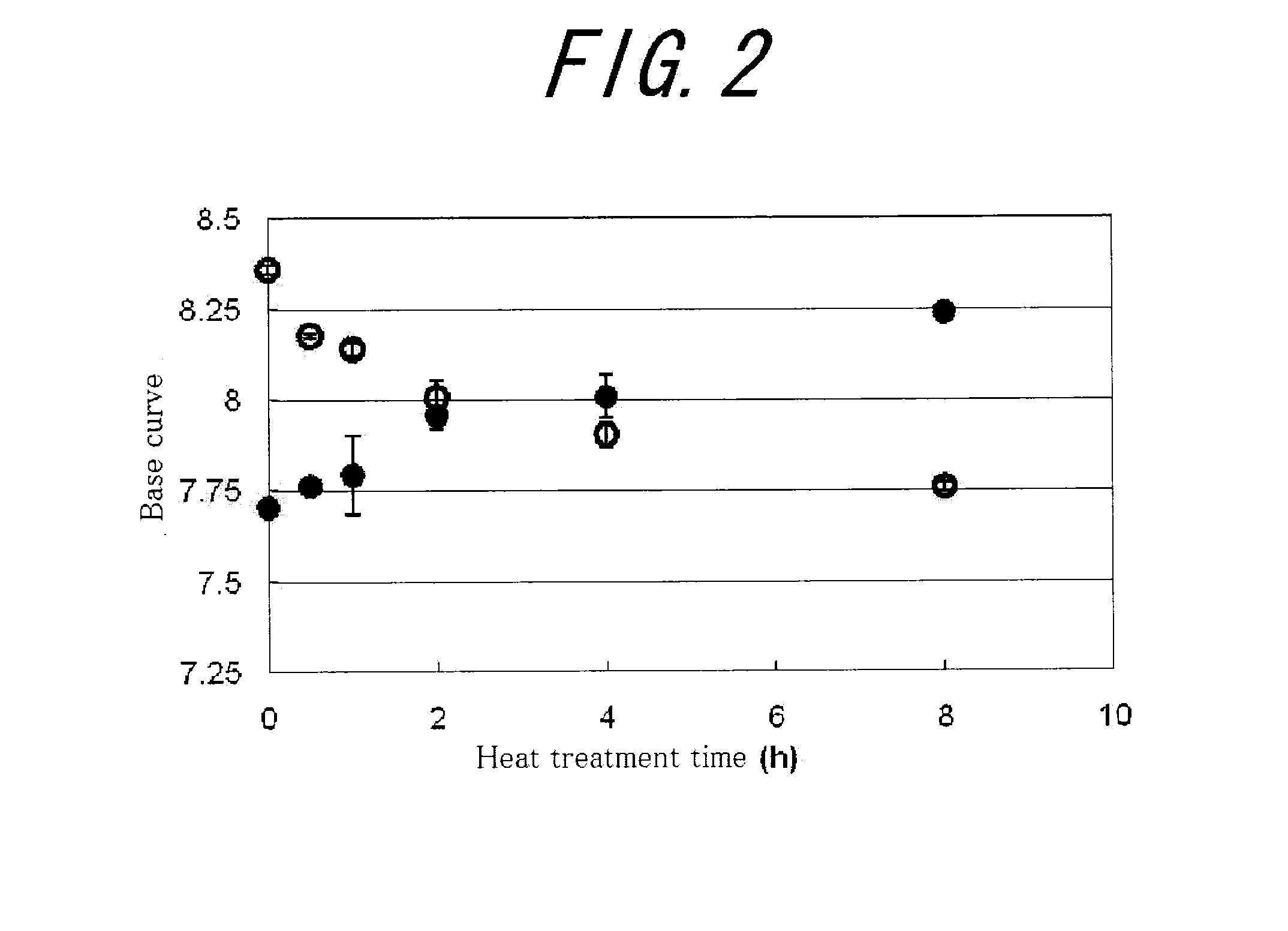

[0088]An aromatic polycarbonate polarizing lens from [2] obtained in the above (b) was subjected to heat treatment at a temperature of 130° C. using a forced hot air circulation oven for the time until the resolving power became not less than 20. At the heating temperature of 130° C., the resolving power became not less than 20 in the heating time of 1 hour.

[0089]In addition, when the base curves of the aromatic polycarbonate polarizing lens with a resolving power of not less than 20 were measured, the anisotropy of the base curves was not more than 0.1.

[0090]While the heating temperature was 120° C. and the heating time required for the anisotropy of the base curves to be not more than 0.1 was 12 to 48 hours in Example 1, the anisotropy of the base curves became not more than 0.1 in the heating time of 1 hour in Example 2.

[0091]Thus, by a method of appropriately selecting the temperature of heat treatment, an aromatic polycarbonate polarizing lens with very high shape accuracy coul...

reference example 1

[0092]Aromatic polycarbonate polarizing lenses prepared under each injection molding condition of the above (b) were heat treated at 120° C. for 1 hour using a forced hot air circulation oven. This heat treatment corresponds to calcination conditions of a hard coating of the conventional techniques.

[0093]The base curves of aromatic polycarbonate polarizing lenses before and after heat treatment were measured for 10 samples each, and the average values are shown in Table 3.

[0094]In aromatic polycarbonate polarizing lenses from all molding conditions [1] to [9], while the anisotropy of the base curves could be reduced after heat treatment as compared to the immediate post injection molding, it could not sufficiently be reduced for some molding conditions.

[0095]In these molding conditions, while there were molding conditions where the anisotropy of the base curves became not more than 0.25, this is the average value of 10 samples, all samples did not necessarily become not more than 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

| Nanoscale particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap