Additive for hydroconversion process and method for making and using same

a hydroconversion process and additive technology, applied in the field of additives, can solve the problems of high metal, sulfur and asphaltene content of hydroconversion processes in general, inability to achieve high conversion (more than 80wt%) without recycling, and more difficult by-product processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Coke / Asphaltene Scavenger Capability

[0052]This example illustrates asphaltenes, coke and / or polycondensed ring aromatic compounds catching capability of the carbonaceous additive.

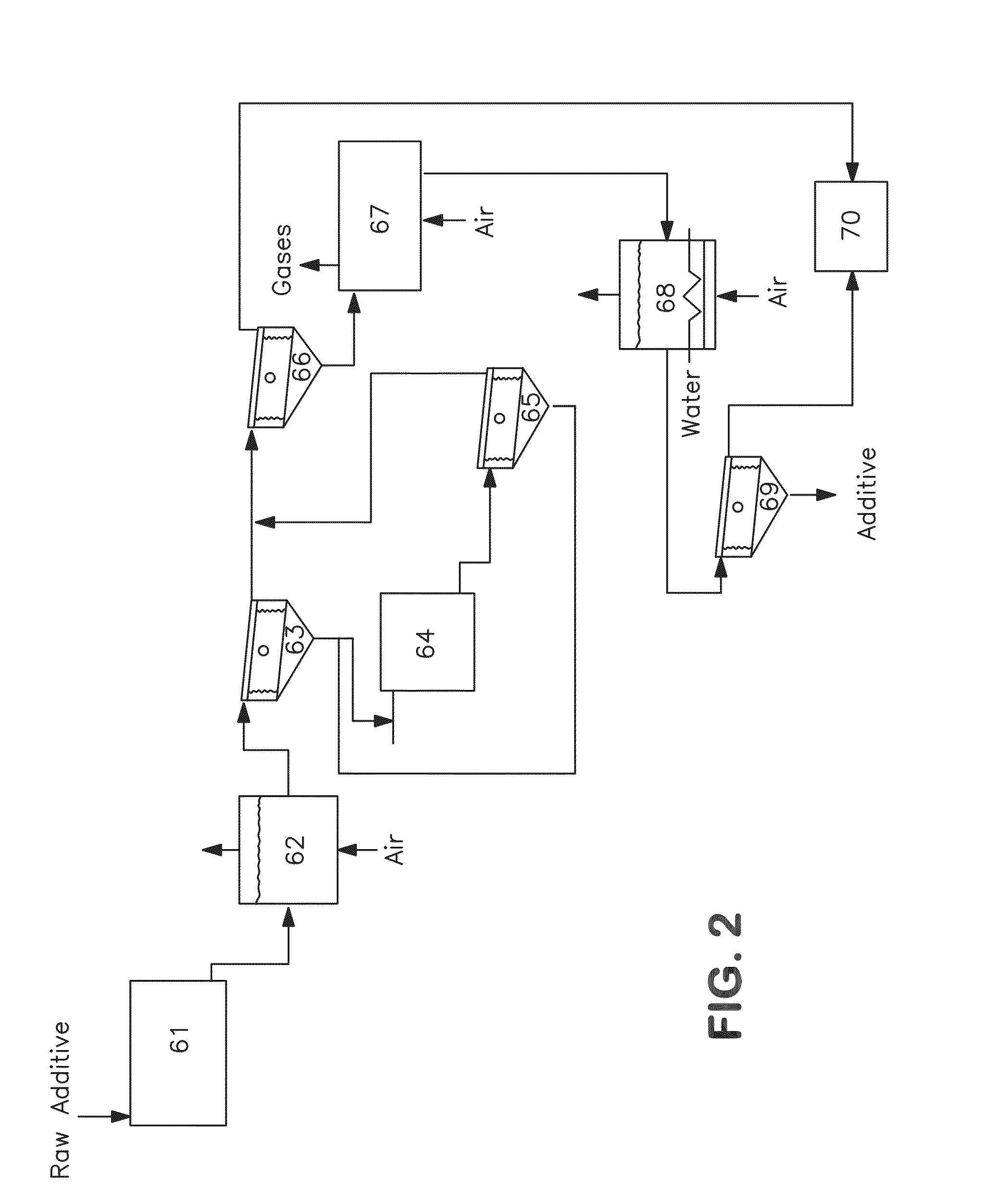

[0053]In this example, Petrozuata petroleum coke was used to generate the carbonaceous additive, this coke comes from delayed coking process. This coke was thermally treated through a moderate combustion process (porogenesis) with air to generate some porosity and surface area. The particle size was adjusted in the range of 200-900 μm, following the scheme represented in FIG. 2, the carbonaceous additive was generated and the following experimentation was effected.

[0054]Table 55 shows Petrozuata coke composition.

TABLE 5Elementwt %Carbon86.6-88.9Hydrogen4.2-4.7Sulfur4.4-4.8Vanadium0.20-0.22Nickel0.30-0.54Iron0.106Ashes0.21-0.52Volatiles 9.9-12.0

[0055]10 g of Merey / Mesa vacuum residue (VR) were mixed with 100 ml of toluene; the mixture was placed in stirring to dissolve the VR. After that, 120 ml of n-heptane...

example 2

[0057]This example illustrates metal scavenger capability of the carbonaceous additive.

[0058]In this example, flake like material containing the unconverted vacuum residue and the remaining organic additive was used to quantify the metal content and metal mass balance of the hydroconversion process.

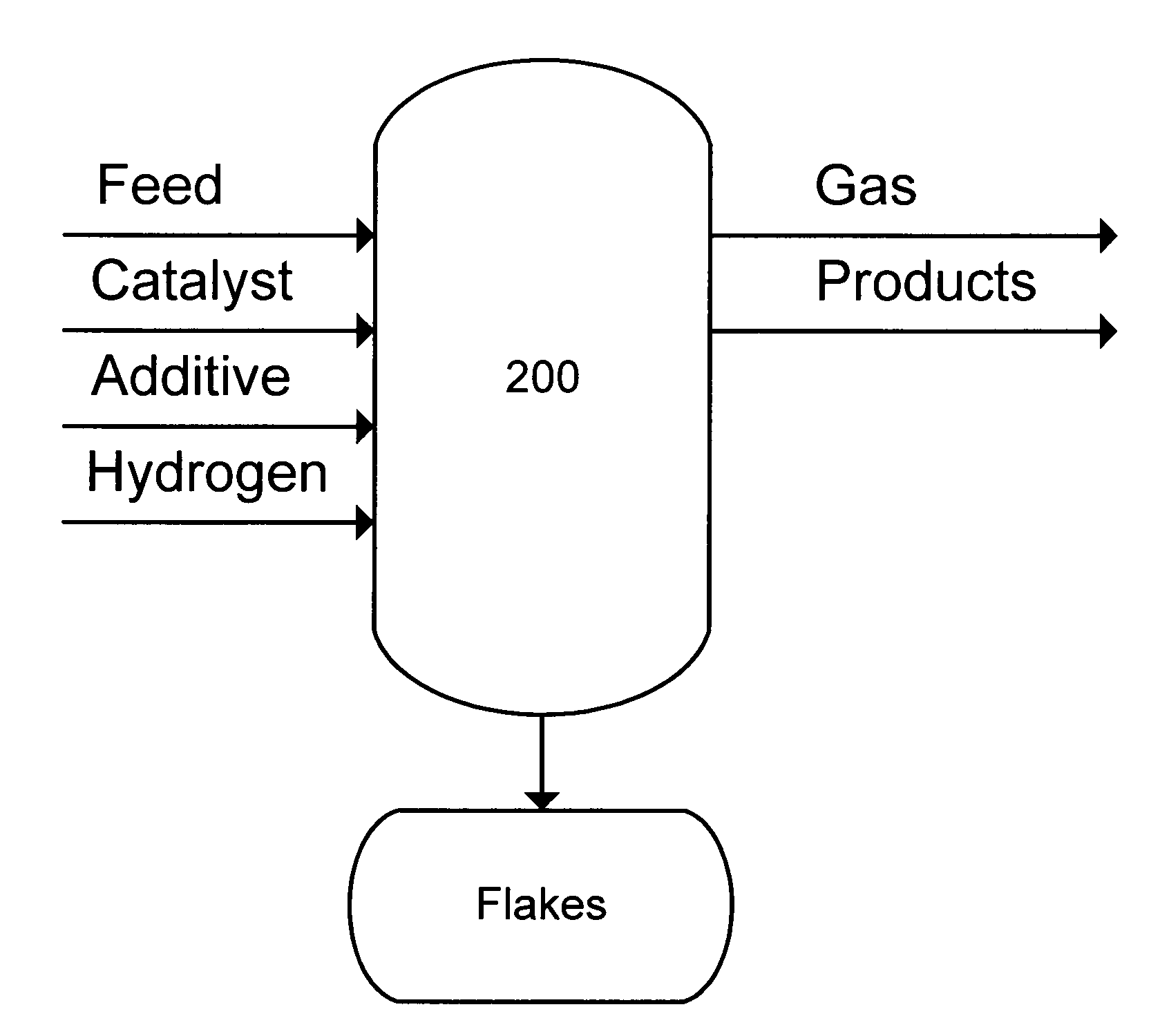

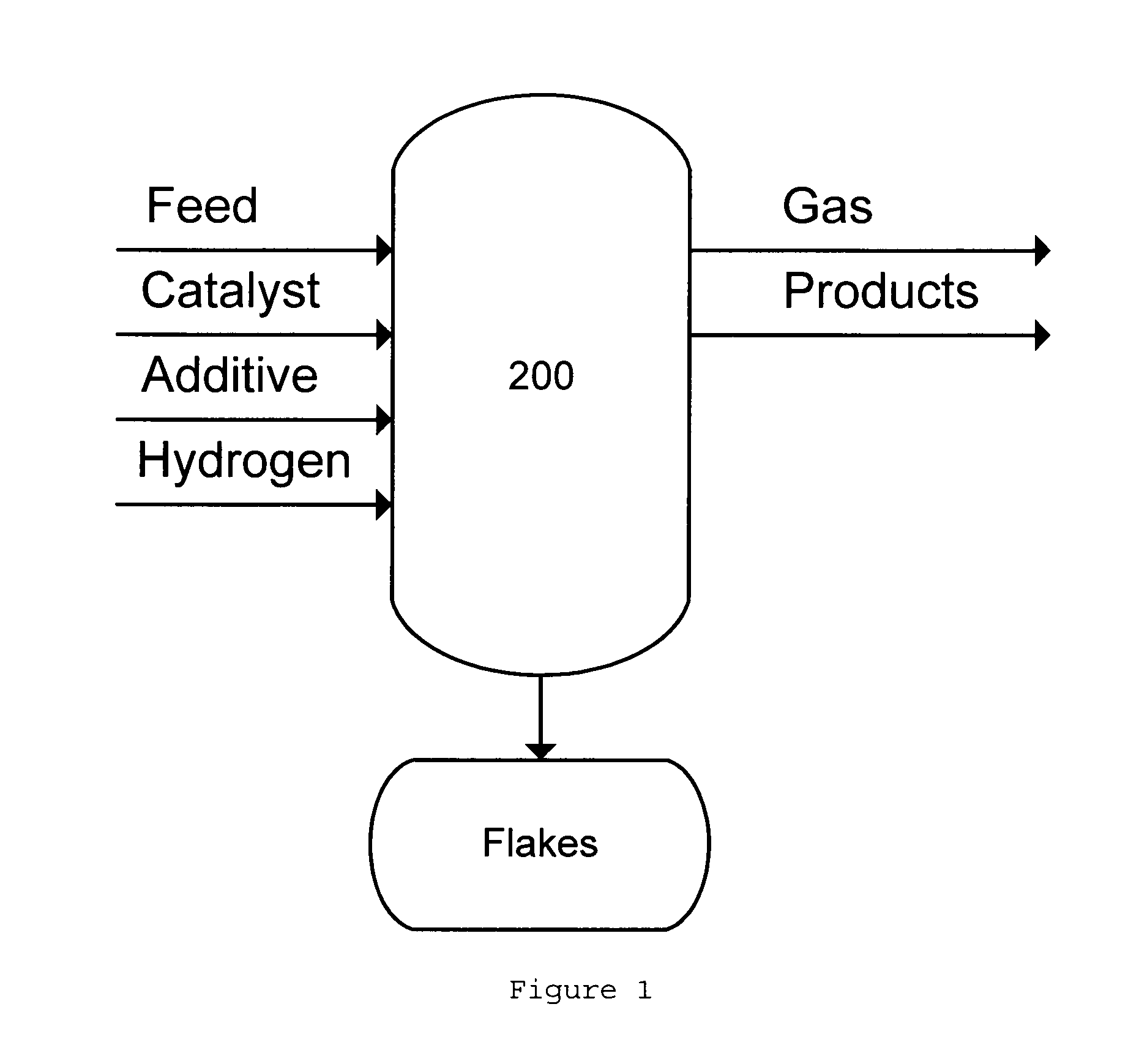

[0059]In this example the remaining organic additive was separated by using a desolidification procedure with toluene as solvent. Following the scheme represented in FIG. 1, flakes where generated and the following experimentation was effected.

[0060]50.00 g of flakes were dissolved in 350 ml of hot toluene, this mixture was then centrifuged at 1500 rpm for 20 minutes to separate the unconverted residue of the additive. The solids were decanted and washed using toluene Soxhlet extraction, which is a continuous extraction method whereby fresh solvent continuously flows through the compound to be extracted. After that, the solids were dried in a vacuum oven for two hours at 13...

example 3

Fluid-Dynamic and Temperature Control

[0063]Following the scheme represented in FIG. 1, the following experimentation was effected.

[0064]The test was carried out using sample of vacuum residue (VR) of Canadian oil, prepared from Athabasca crude.

[0065]This VR was fed into a slurry bubble column reactor without any internals, with a total capacity of 10 BPD, with a temperature control based on a preheater system and cool gas injection. This reactor has a length of 1.6 m and a diameter of 12 cm.

[0066]For this test the reactor was operated at 0.42 T / m3h. Three serially connected vertical slurry reactors were used during this test. The conditions were maintained for 11 days.

[0067]Conditions are summarized in Table 8.

TABLE 8Feedstock characteristicsAPI density (60° F.)2.04Residue 500° C.+ (wt %)97.60Asphaltenes (insolubles in heptane) (wt %)21.63Metal content (V + Ni) (wtppm)462Sulfur (wt %)6.56Process variablesWSHV (T / m3h)0.42Feedrate (kg / h)24Total pressure (barg)169Reactor average temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| skeletal density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com