High modulus polymeric ejector mechanism, ejector device, and methods of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a

Modes of Operation

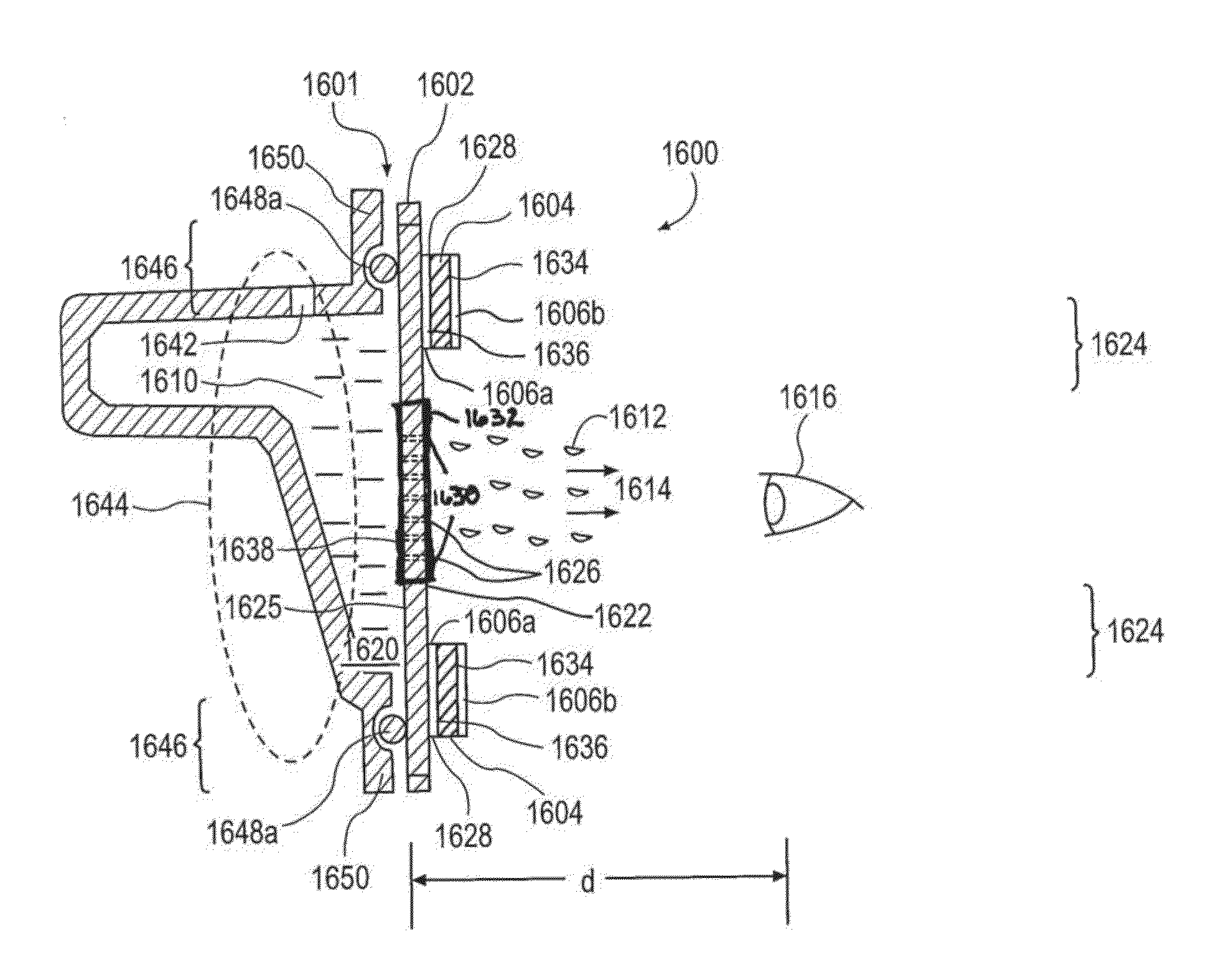

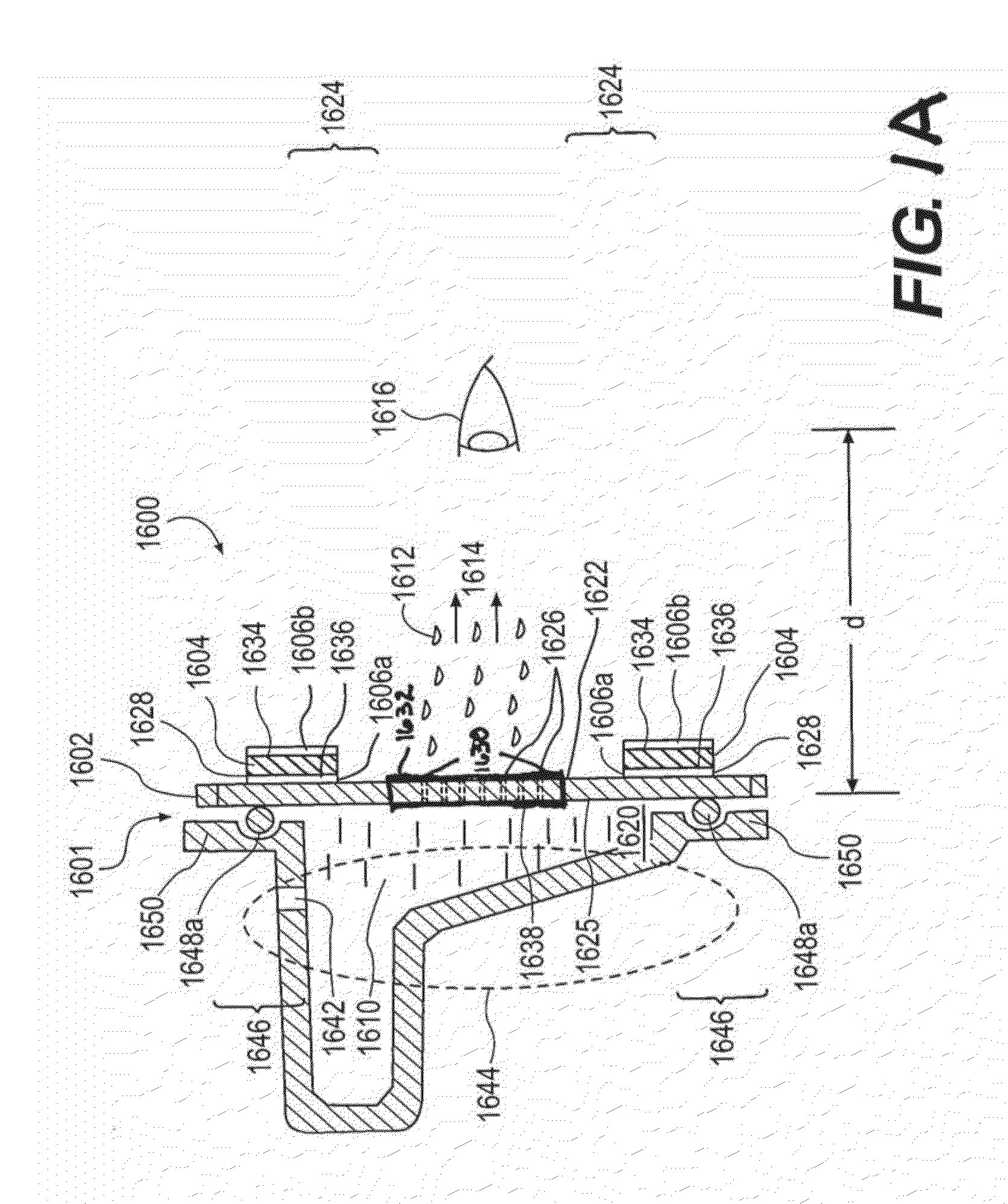

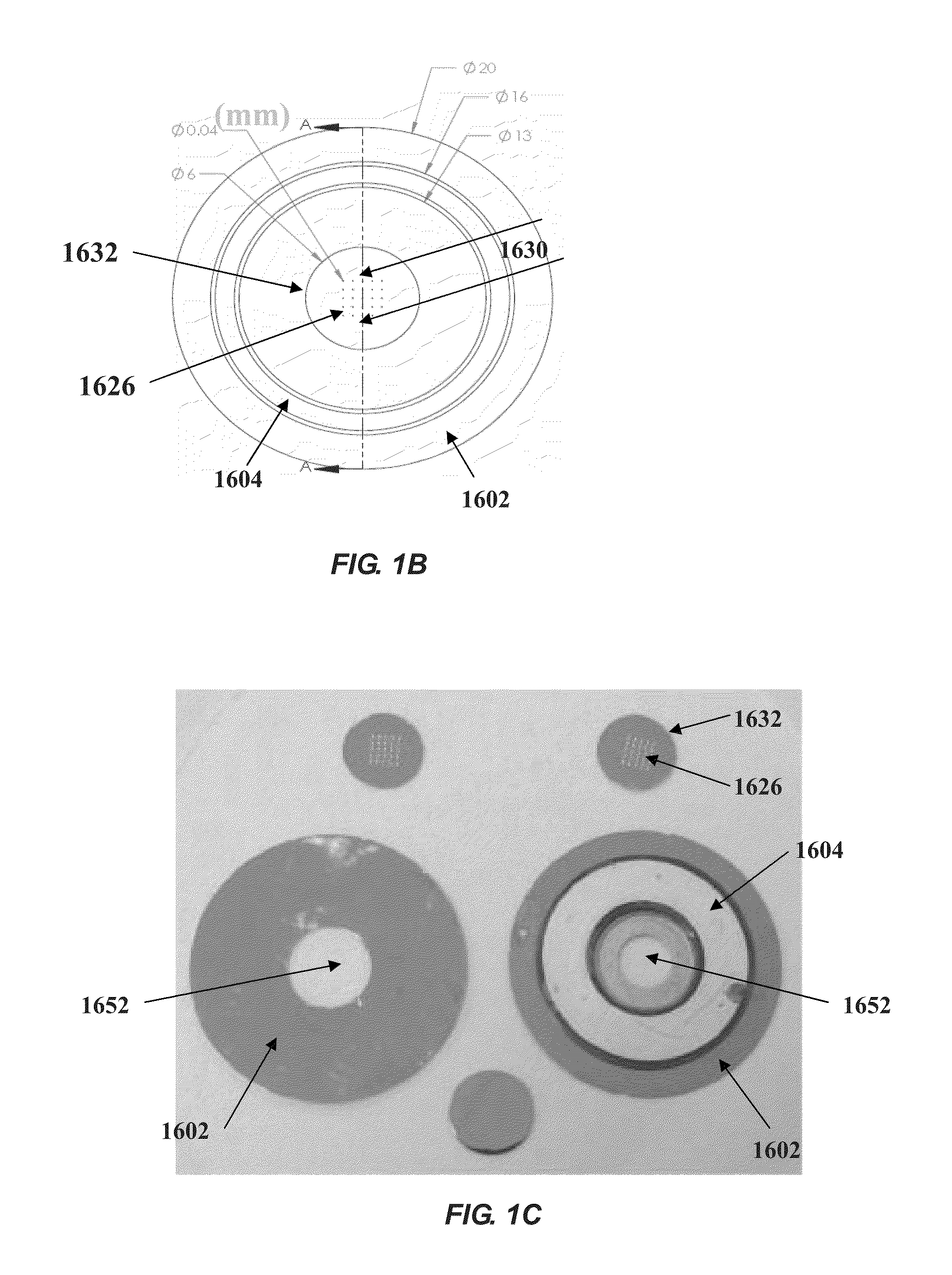

[0093]Although many arrangements are possible, one implementation uses a piezoelectric-driven ejector mechanism which includes a 6 mm outer diameter, 300 μm thick PEEK generator plate that is bonded to a 20 mm outer diameter, 50 μm thick 304 stainless steel ejector plate annulus. The ejector plate annulus includes a 4 mm diameter central opening which is aligned with the PEEK generator plate, and a 16 mm outer diameter, 8 mm inner diameter piezoelectric actuator is attached directly to the ejector plate. A modulation frequency of approximately 108 kHz to over 140 kHz is applied to the piezoelectric actuator, causing the ejector plate to oscillate. Digital holographic microscopy images are captured to observe oscillation of the high modulus polymeric generator plate. By way of example, with reference to FIG. 5, a frequency scan of the implemented ejection assembly vs. oscillation amplitude was performed to provide for identification of optimal resonant frequency and...

example b

Spray Performance

[0095]Ejector assembly performance may be evaluated over a range of fluid viscosities from low viscosity, e.g., using distilled water (viscosity 1.017 cP), to high viscosity, e.g., using medications such as an ophthalmic emulsion of cyclosporine such as Restasis™ (dynamic viscosity=18.08 cP). By way of example, ejector assembly performance may be evaluated by analyzing fluid mass ejection as a function of actuation frequency.

[0096]The mass ejection profile closely tracks the membrane oscillation amplitude with a maximum mass ejection at ˜110 kHz and maximum oscillation amplitude of ˜2 microns at 110 kHz. Ejection of low viscosity fluids (water) was observed with capillary lengths of both 70 and 120 microns. With reference to FIG. 6, mass ejection vs. frequency for water using a 300 μm thick PEEK generator plate with 70 μm capillary channel length is illustrated, with an onset of maximum amplitude at 108 kHz and a maximum amplitude of 2.3 μm at 110 kHz, which coincid...

example c

Effect of Capillary Length

[0097]In certain implementations of ejector mechanisms of the disclosure, capillary length of the openings of the generator plate may affect spray performance. As illustrated in FIGS. 7A-7B, mass ejection vs. frequency reveals a shift in frequency, to lower frequencies, for water ejected from PEEK membranes having 120 micron long capillary channels. However, for high viscosity fluids such as Restasis™ (dynamic viscosity=18.08 cP), a significant increase in the mass ejection peak (2.5×) for PEEK membranes with 120 micron long capillary channels vs. membranes with 70 micron long capillary channels is observed.

[0098]More particularly, FIG. 7A illustrates ejection of Newtonian fluids (water), while FIG. 7B illustrates ejection of Non-Newtonian fluids (Restasis). FIG. 7A shows that an increase in capillary length leads to an increase in resistance and load on the fluid as it exits the opening. This mass loading effect leads to a shift in the peak ejection freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com