Besides unavoidable servicing, a great deal of flight capacity is lost in the so-called turnaround of the aircraft, in which the aircraft is unloaded and loaded between landing and take-off.

It has been observed that one

bottleneck in the turnaround of an aircraft particularly concerns the handling of piece goods, such as bags and packets, to be loaded into the hold.

On the other hand, a short stopover time puts considerable pressure on the baggage

handling system.

The drop in the

level of service relating to baggage handling, experienced by passengers especially in recent years, is a nearly direct result of increased air traffic, of the increased handling and

security check time required by the baggage moving in it, which additional investments in conveyor and

automation technology made in airport infrastructure have been unable to correspondingly shorten, and the increase in the costs relating to a labour-intensive operating culture.

As is known, the loading of piece goods to be transported by air has been quite labour intensive.

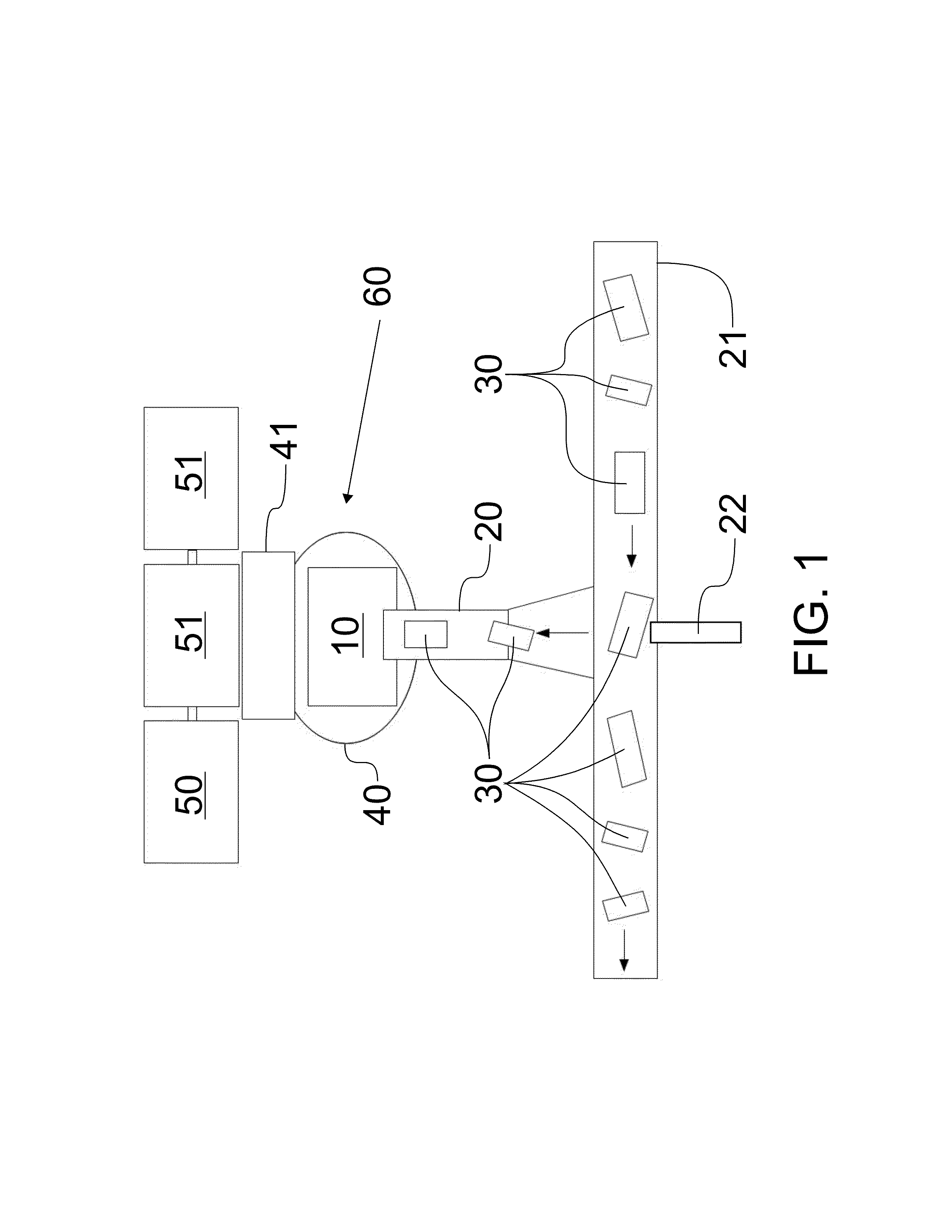

However, a single

robot cell at Amsterdam Schiphol airport is the only known

system in practical operation.

Despite an extensive and known customer need, corresponding

robot cells have not, however, spread for use in other airports.

Significant drawbacks are associated with the prior art.

It is obvious that the manual packing of bags and other piece goods is disadvantageous.

First of all, a

loader's work is extremely stressful, as the manual transfer of bags weighing as much as 40 kg in three shifts is wearing on the employees both physically and mentally.

For example, in Denmark, a 4000-kilogramme lifting limit during a

work shift, in force in 2010, has had the effect that baggage can only be handled for a few effective

working hours.

Packing bags manually is not only unreliable, but also extremely expensive.

For example, solely the packing costs of the personnel forming packing at Helsinki-Vantaa airport are several million euros annually.

Besides the costs and low reliability as well as the uneven daily traffic distribution of air-traffic timetables of a typical airport, labour

capacity planning is quite difficult, because it is a challenge to recruit professional, security-cleared, and reliable temporary labour only to even the peak-period

workload.

Supervisors, who are under continual pressure to produce savings, clearly prefer to underman shifts, rather than dimension capacity to be adequate, which, for its part, causes undesirable stress and other injuries due to hurry and tiredness, arising from unpredictable variations in

workload.

Though there has been a long-term need for the

automation of the loading of air-transport units, projects like the

robot cell operating at Schiphol airport have not become widespread.

The reason for this is the complexity of robot systems and the unreliability this causes, as well as the relatively long time, of as much as 15 seconds, taken to automatically load a bag.

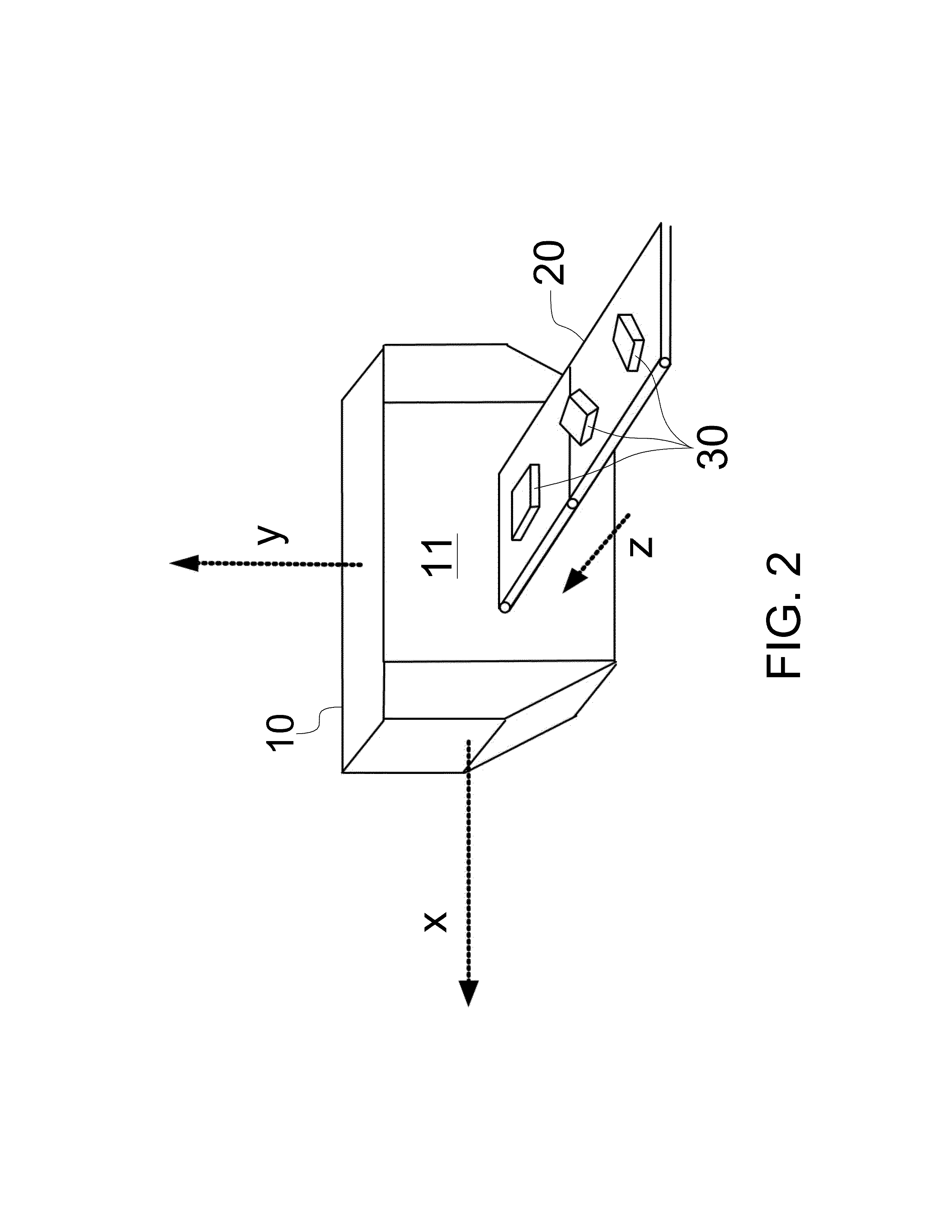

Loading carried out by robots is also challenging because the sizes of the bags on a

conveyor belt are not known precisely, so that stacks are formed to some extent in an irrational order.

This causes the stacks of bags to be packed to fall over easily, which leads to an

error state, which must be rectified by human labour.

In turn, this means that the movements of the robot must be very slow in order to avoid falling, so that at least part of the speed

advantage brought by robotization is not achieved.

Thus, the known automated systems are neither particularly robust nor fast.

In addition, due to the complexity of the known automated systems, they are difficult to integrate with the existing infrastructure and the investment costs are high and challenging for those making

purchasing decisions.

Because these solutions have little or no advance information available on baggage, and both the precision of the sensors and image-

processing solutions and the computing capacity are limited, the measurement and calculation of the degree of filling and of the remaining empty space are naturally in practice uncertain and challenging.

When containers are filled manually, or using a known robot arrangement, the first containers are in practice filled only reasonably full, because packing really full is not only an intellectual challenge to people, but also physically considerably heavier and slower to implement.

In addition, the number of containers reserved for baggage in an aircraft is not at all tightly limited, so that, for example, the use of one ‘extra’ container may not mean anything to the

loader, except to make his own task easier.

In addition, the statistical nature of the phenomenon leads to the fact that the last container or containers of those to be packed into a single aircraft load always remain partly empty.

One of the greatest challenges of the baggage-packing automation solutions presented in the literature and implemented in practice is that their introduction requires significance alterations to airport infrastructure—often even building baggage transport and sorting equipment from the very start around the packing-robot

cell.

Login to View More

Login to View More  Login to View More

Login to View More