Low air-permeable high-density woven fabric

a high-density, air-permeable technology, applied in the field of high-density woven fabrics, can solve the problems of difficult water penetration into the woven fabric, difficult drying, and difficult penetration of water, and achieve excellent rub-resistant water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

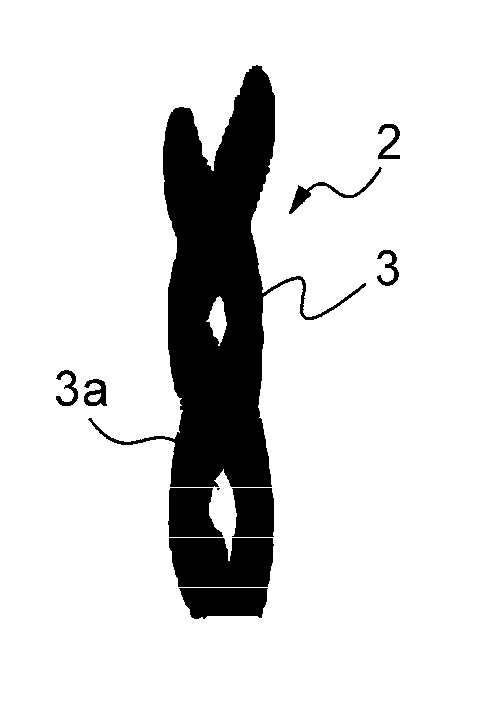

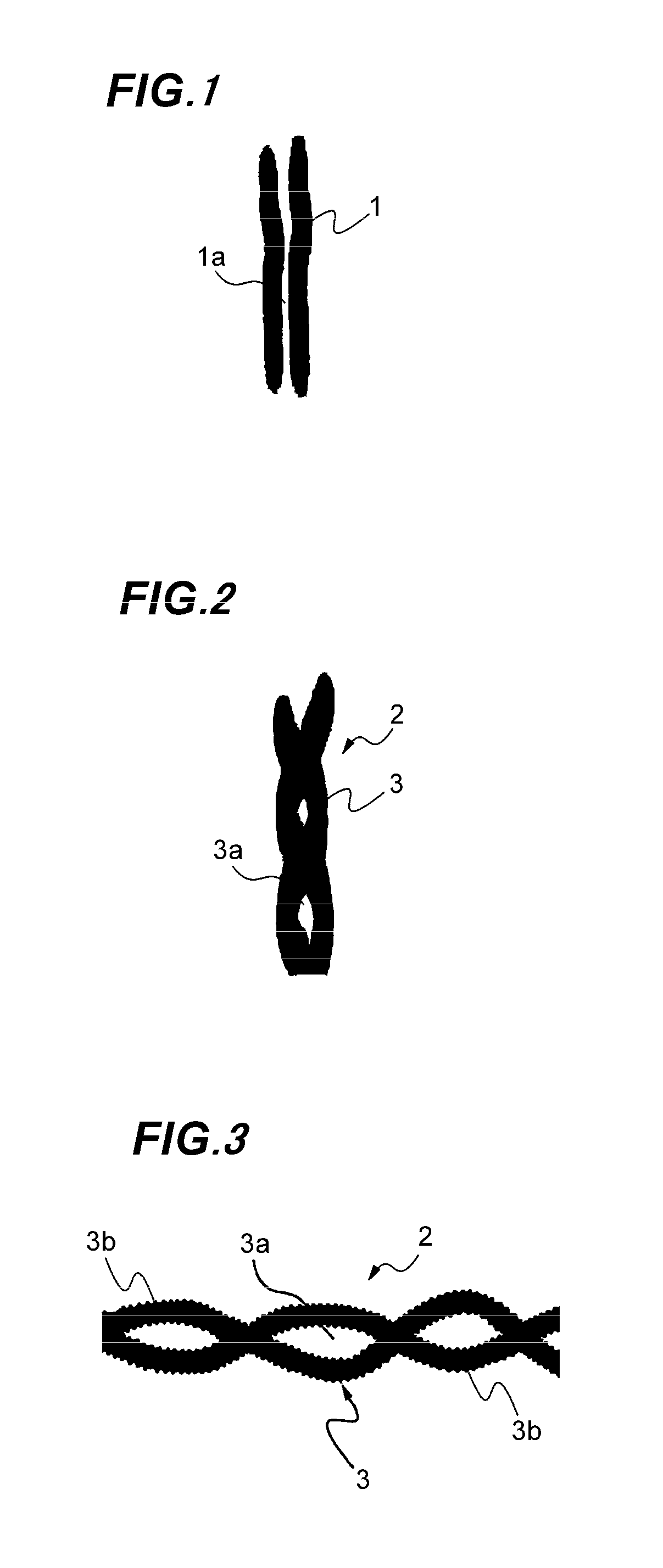

Image

Examples

reference example 1

[0039]A woolly filament yarn (single-yarn denier 1.04) of 75 denier / 72 filaments was twisted 2000 turns / M, and the resulting high twisted yam was used as the warp and weft. The fabric woven by the yams (an S-twist yarn was used as the warp, and an S-twist yarn and a Z-twist yarn were alternately used as the weft), was scoured, relaxed, dyed, and finished in a usual manner to give a low air-permeable high density warp mat plain-woven fabric of this reference example. This reference product had a warp density of 216 yarns per inch and a weft density of 86 yarns per inch. As a result of calculation, the twist coefficient of the high twisted multifilament yarns was 17321, and the cover factor of the entire woven fabric was 2615.

[0040]For comparison, the same woolly filament yarn (single-yam denier 1.04) of 75 denier / 72 filaments as in this reference example was used. As the warp, the yarn was weakly twisted 300 T / M to such a degree that problems in weaving would be avoided. Meanwhile, a...

example 1

[0044]The woven fabrics of Reference Example 1 and Comparative Example 1 were each subjected to water-repellent treatment with a fluorine-based water repellent agent (Asahi Guard AG-710, manufactured by Asahi Glass Co., Ltd.; a 7% aqueous solution was used) in a usual manner and then calendered to give Example 1 and Comparative Example 2. The following Table 2 shows the water-pressure resistance, water repellency, and rub-resistant water repellency of Example 1 and Comparative Example 2.

TABLE 2Water-PressureWater RepellencyRub-ResistantResistance (mm)(level)Water RepellencyExample 12805200 or moreComparative480530Example 2

[0045]It was shown that in Example 1, rub-resistant water repellency. which is novel water repellency, is much higher than in Comparative Example 2.

reference example 2

[0046]In place of the woolly filament yarn (single-yarn denier 1.04) of 75 denier / 72 filaments used in Reference Example 1, a woolly filament yarn (single-yarn denier 0.52) of 75 denier / 144 filaments was S-twisted 2000 T / M, and the resulting high twisted textured yarn was used as the warp, while the same yarn as used for the warp was twisted 1500 T / M, and the resulting S-twist and Z-twist high twisted textured yarns were alternately used as the weft. The fabric woven by the yams was scoured, relaxed, dyed, and finished in the same manner as in Reference Example 1 to give a low air-permeable high-density warp mat plain-woven fabric of Reference Example 2. The woven fabric of Reference Example 2 had a warp density of 224 yarns per inch and a weft density of 84 yarns per inch. As a result of calculation, the twist coefficient of the warp high twisted multifilament yarn was 17321, the twist coefficient of the weft high twisted multifilament yarns was 12990, and the cover factor of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com