Serviceable soffit vent

a ventilator and soffit technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of affecting the appearance of the attic, promoting mold and decay in the attic, and affecting the ventilation of the attic, so as to protect the structural integrity and aesthetic integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

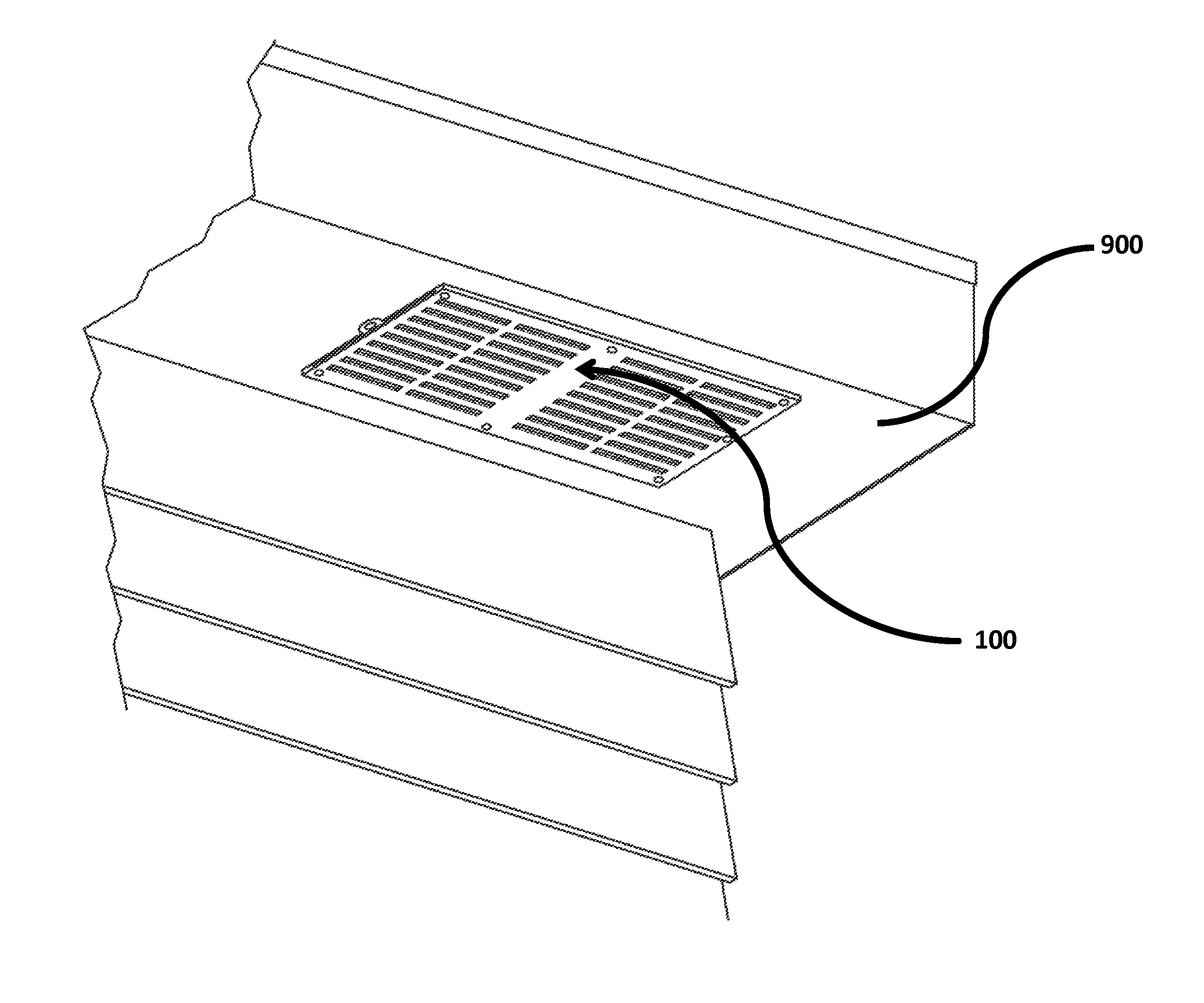

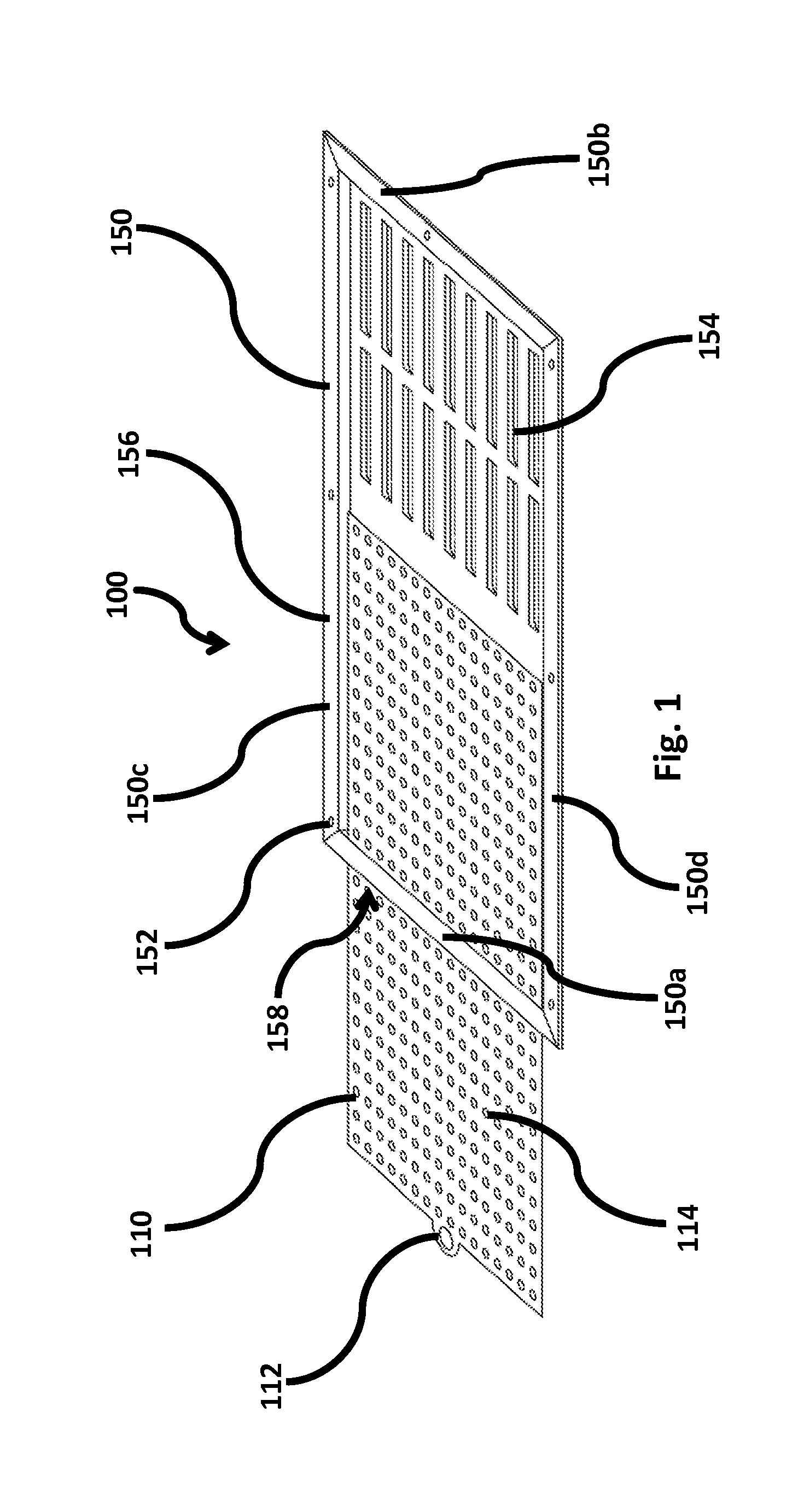

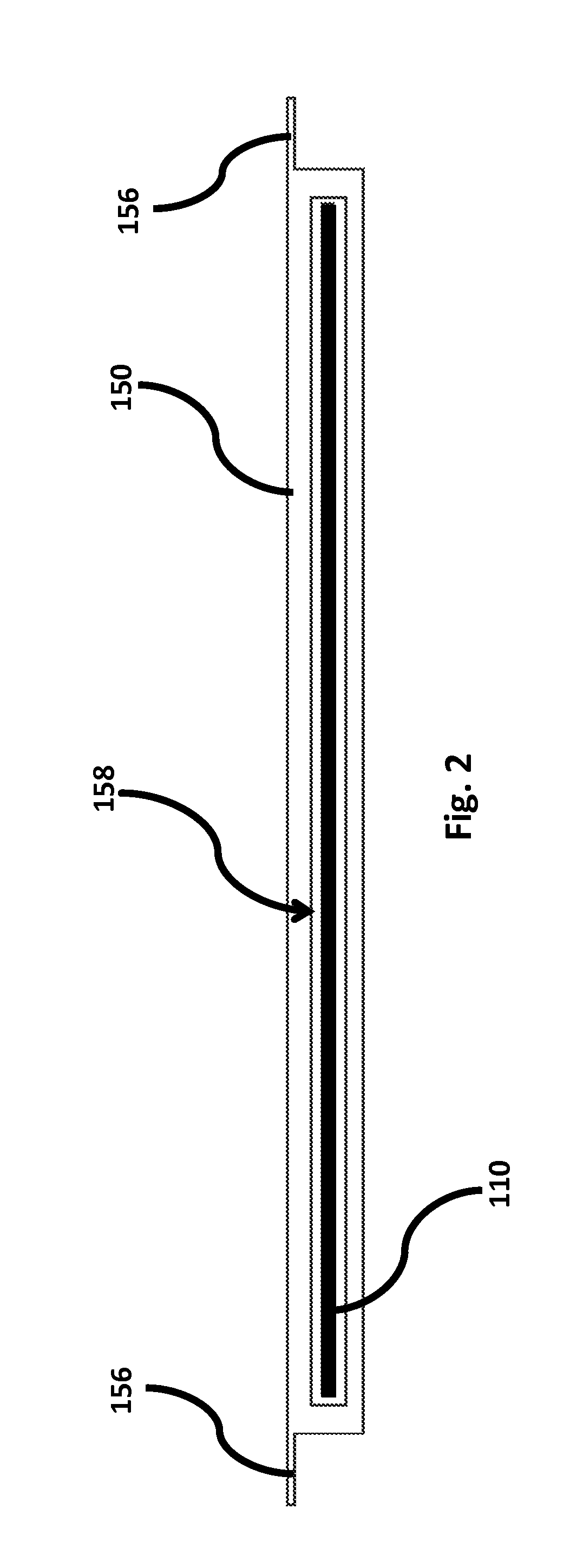

[0019]FIGS. 1-2 illustrate one embodiment of the serviceable soffit vent assembly 100. Here, vent 100 includes a frame 150 having a first end 150a and a second end 150b, top end 150c and bottom end 150d. In the current embodiment, frame 150 has a rectangular configuration, however, it contemplated within the scope of the invention that frame 150 can be any size, dimension, or shape, including but not limited to a square, circle, cylindrical, oval, ellipsoid, triangular, asymmetrical, or any polygon having three or more sides. Further, frame 150 includes a plurality of fixed louvered openings 154. In the current embodiment, there are five columns of louvers, wherein each column has 13, thereby the vent having a total of 65 louvered air openings. However, it is contemplated within the scope of the invention that there can be any number of louvers, louvers columns, air intake openings, or any arrangement or configuration of louvers or air intake openings. In addition, ends 150a-150d of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com