Multi-Functional Hybrid Panel For Blast and Impact Mitigation and Method of Manufacture

a hybrid panel and blast and impact technology, applied in the field of hybrid panels, can solve problems such as weakening of armor, and achieve the effects of reducing the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Various embodiments of the invention are discussed in detail below. While specific implementations are discussed, it should be understood that this is done for illustration purposes only. A person skilled in the relevant art will recognize that other components and configurations may be used without parting from the scope and spirit of the invention. Having specified that alternative embodiments exist and those discussed here are illustrative only, the disclosure turns to a general discussion of the invention.

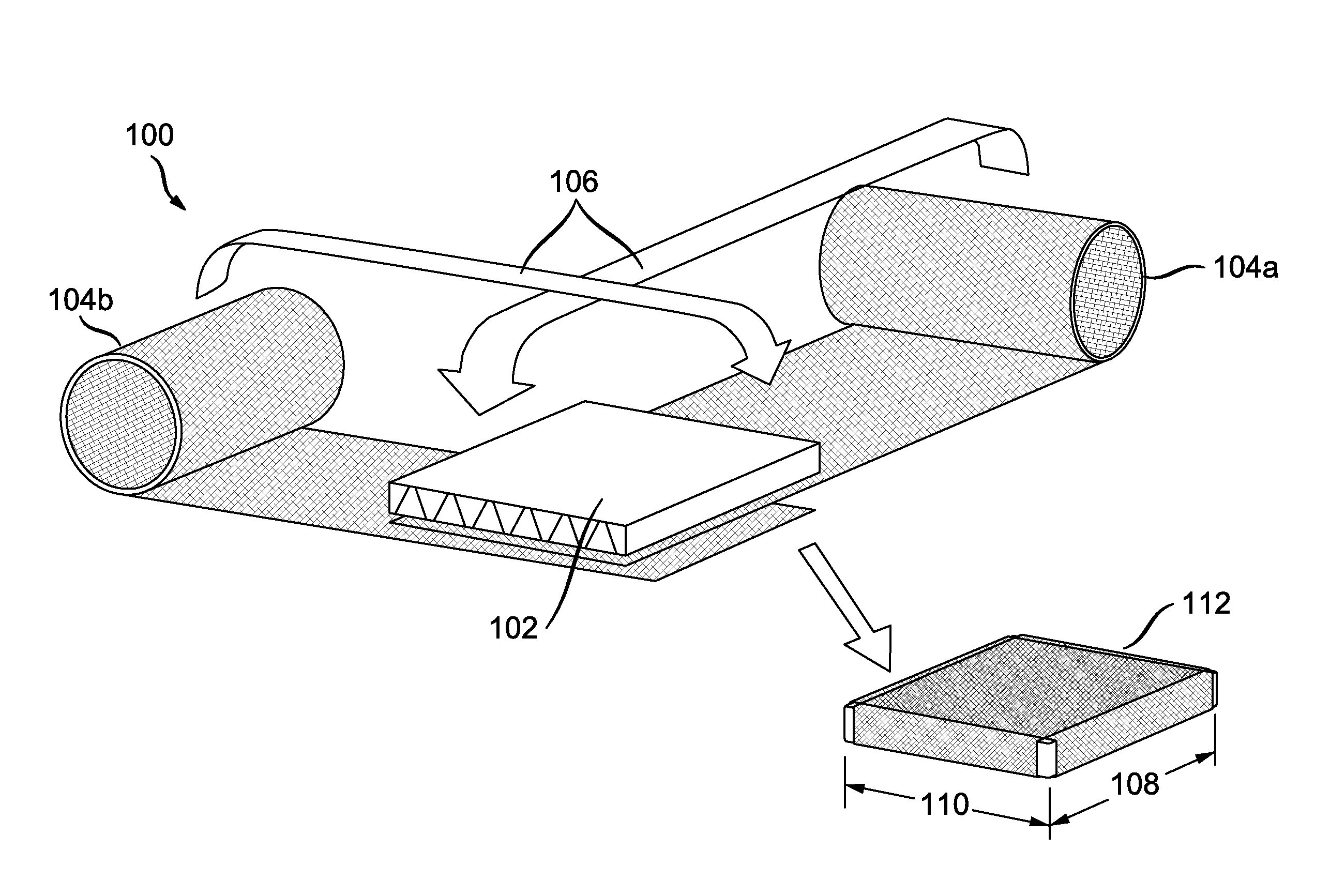

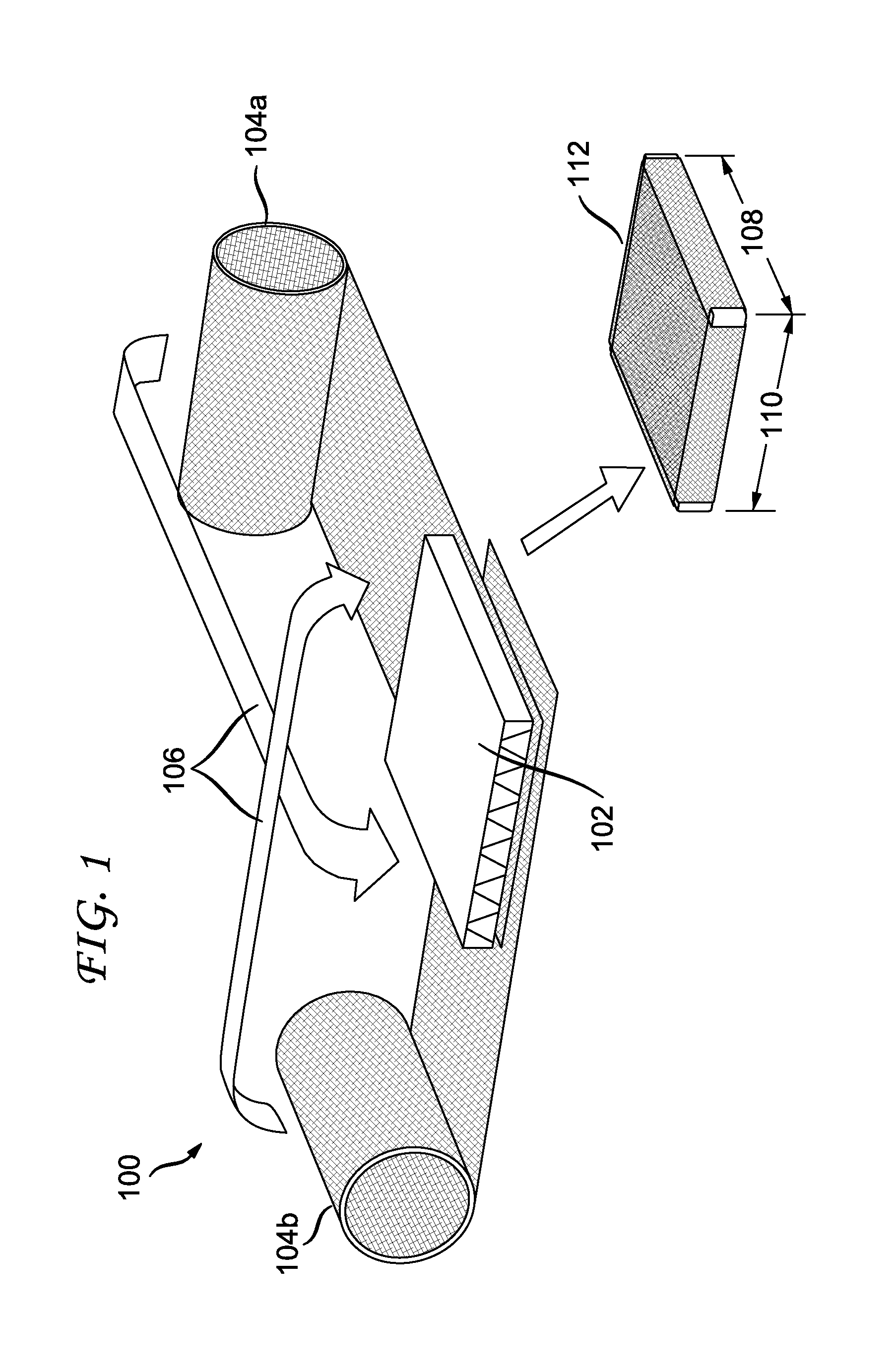

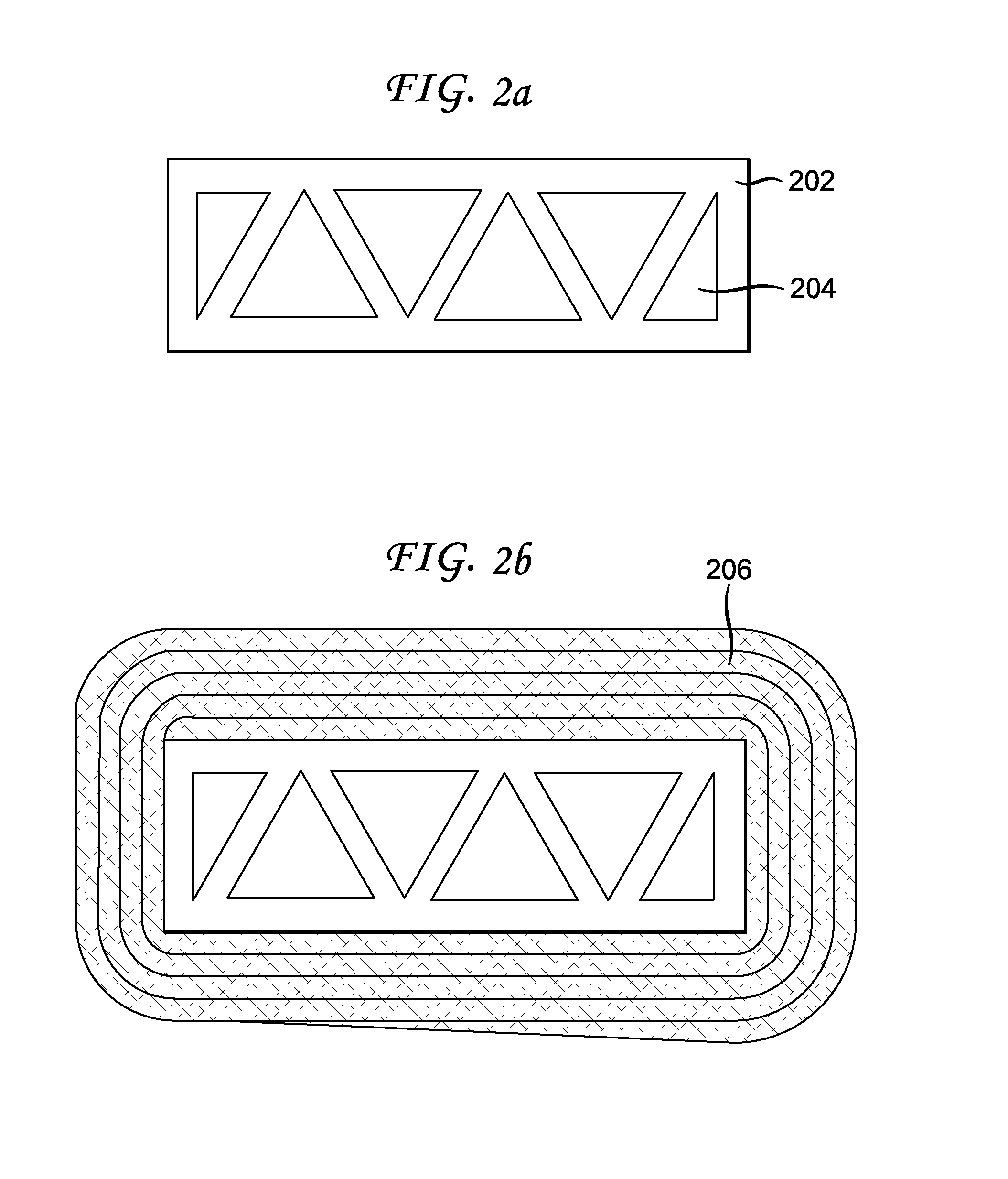

[0021]Disclosed is an improved form of projectile armor, with methods of manufacture and implementation. Units of high-performance fabric are wrapped around a ballistic tile. Exemplary aramid fabrics are woven or layered from Kevlar®, Twaron®, Dyneema®, Spectra®, Zylon®, M5C), Nylon® and IM- or T-series carbon fibers, which all have high-tensile strength to weight ratios several times greater than steel. The number of fabric layers wrapped around a ballistic the can vary,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| metallic | aaaaa | aaaaa |

| lattice structure | aaaaa | aaaaa |

| specific strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com