Seal rings in electrochemical processors

a technology of electrochemical processors and sealing rings, which is applied in the direction of sealing devices, mechanical devices, and the details of semiconductor/solid-state devices, etc., can solve the problems of non-uniform plating, dry contact rings have their own disadvantages, and add to the time requirements and complexity of manufacturing processes. achieve the effect of improving yield, improving performance, and precise sealing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

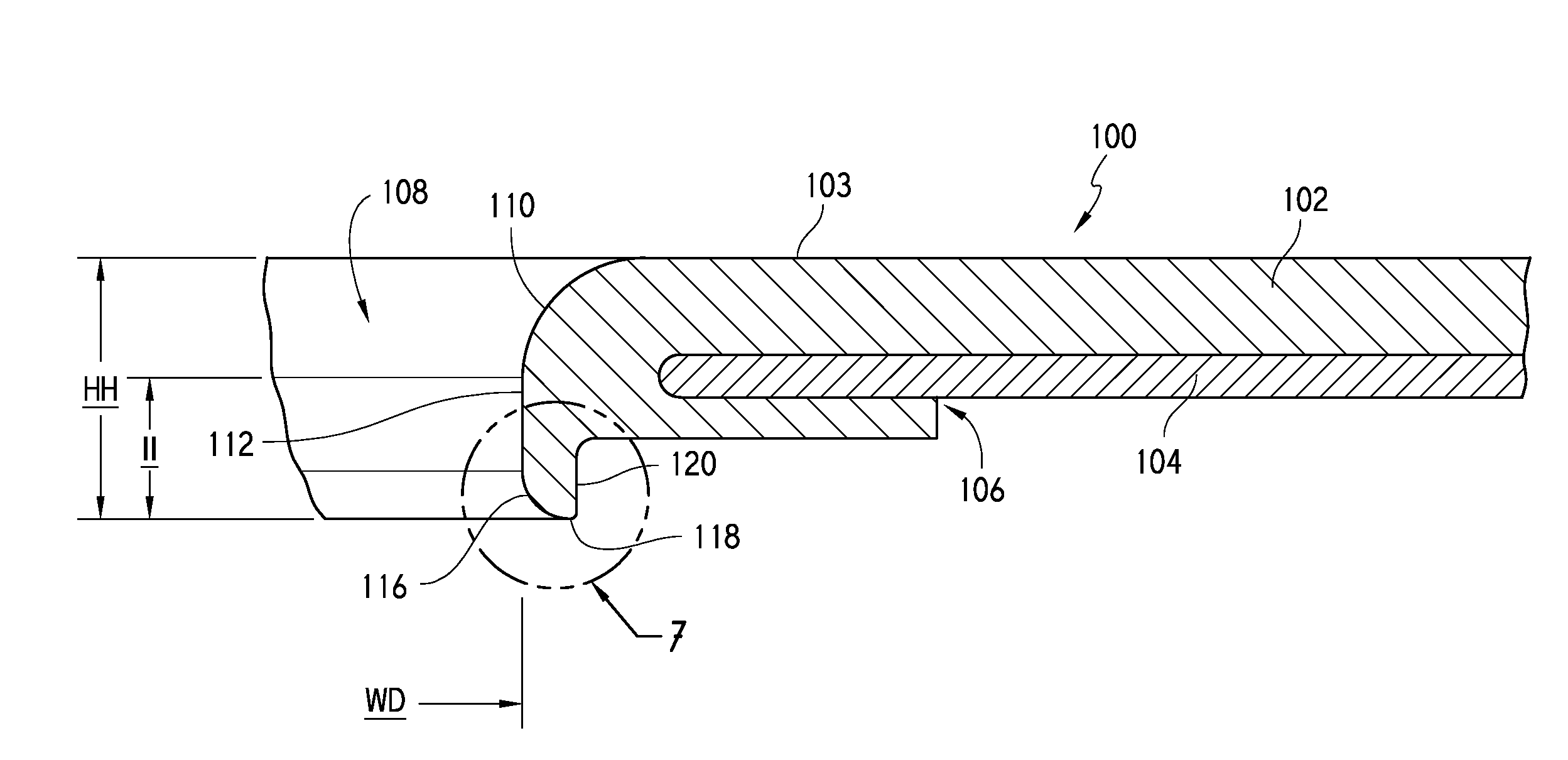

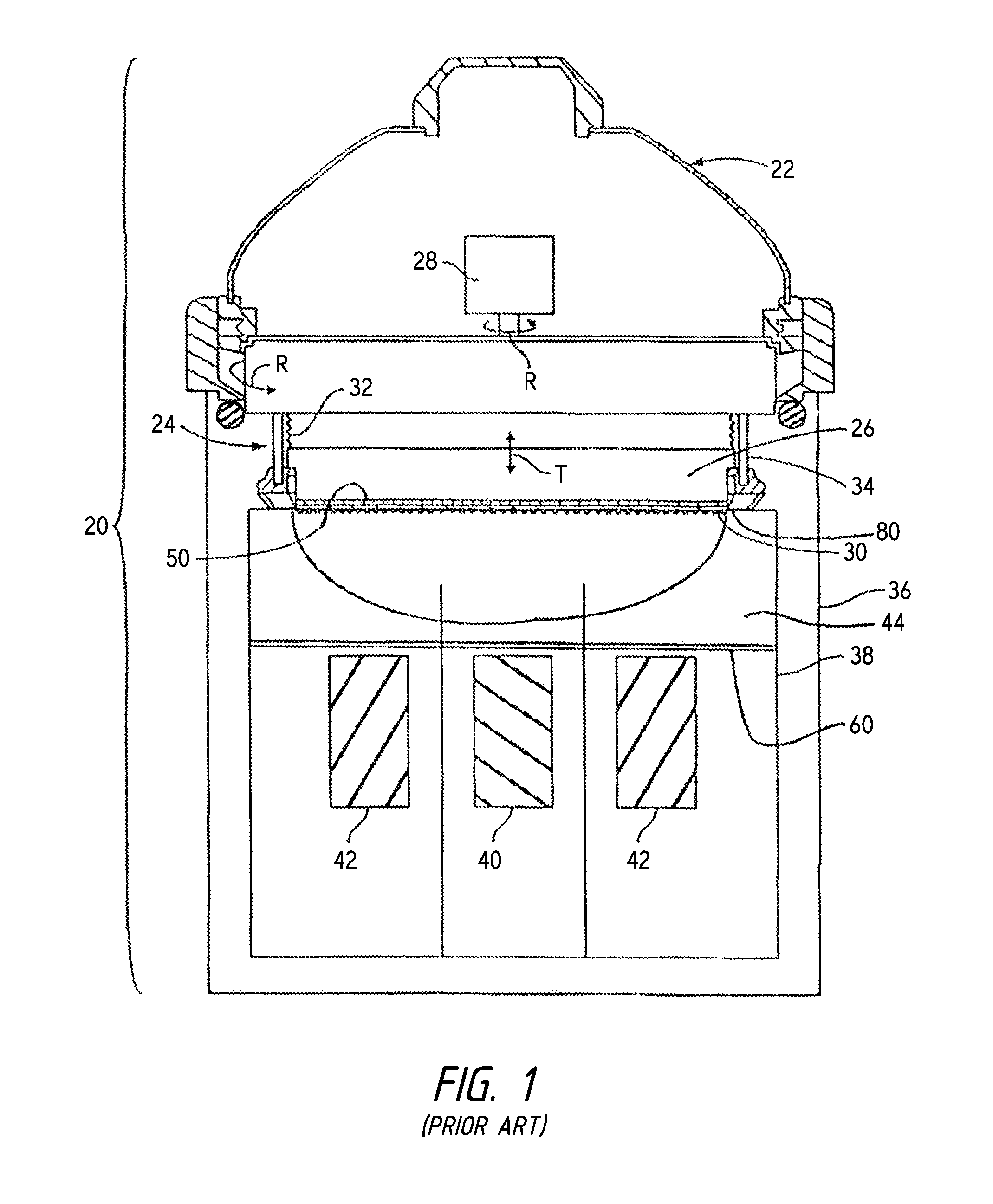

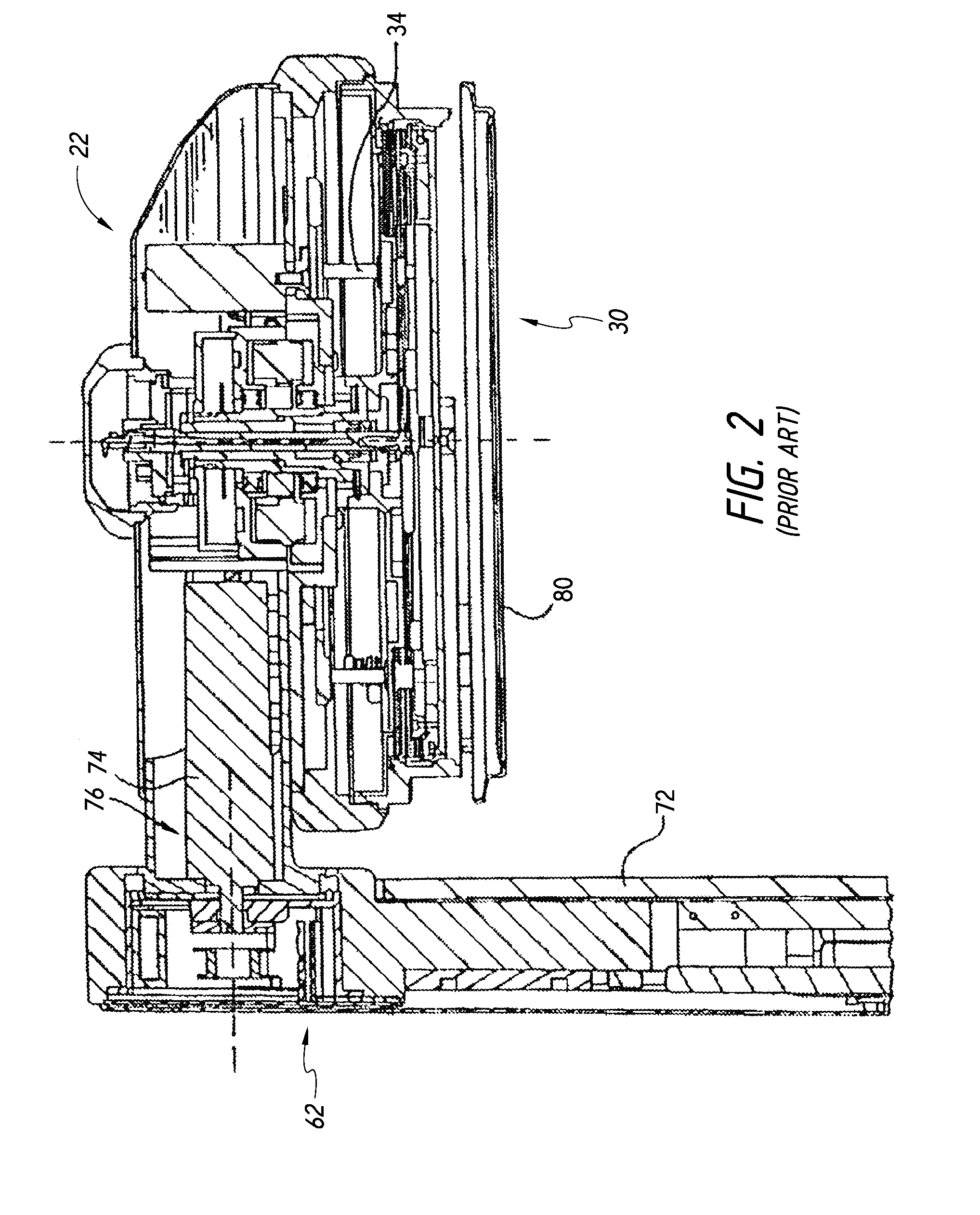

[0015]As shown in FIG. 1, an electrochemical processor 20 has a rotor 24 in a head 22. The rotor 24 includes a backing plate 26 and a contact ring 30 having a seal 80. Contact ring actuators 34 move the contact ring 30 vertically (in the direction T in FIG. 1), to engage the contact ring 30 and the seal 80 onto the down facing surface of a wafer or substrate 50. A bellows 32 may be used to seal internal components of the head. The contact ring typically has metal fingers that contact a conductive layer on the wafer 50. The head 22 is positioned to place the substrate 50 into a bath of liquid electrolyte held in a vessel 38 in a base 36. One or more electrodes are in contact with the liquid electrolyte. FIG. 1 shows a design having a center electrode 40 surrounded by a single outer electrode 42, although multiple concentric outer electrodes may be used. An electric field shaping unit 44 made of a di-electric material may be positioned in the vessel between the electrodes and the wafe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com