Waterproof membranes

a waterproof membrane and waterproof technology, applied in knitting machines, weaving, straight-bar knitting machines, etc., can solve problems such as labor and danger, achieve the effects of improving puncture resistance and waterproofing, increasing the mass or density of the base fabric, and prolonging the long-term performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

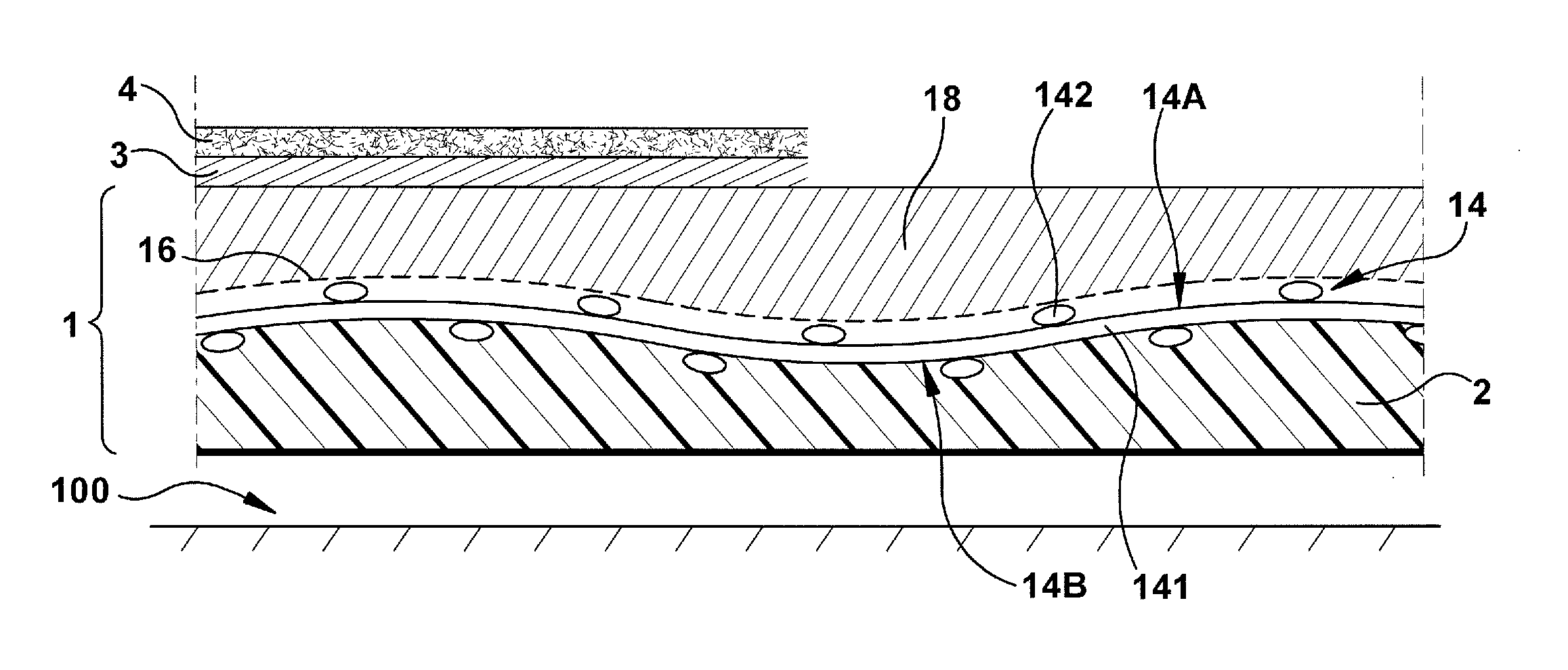

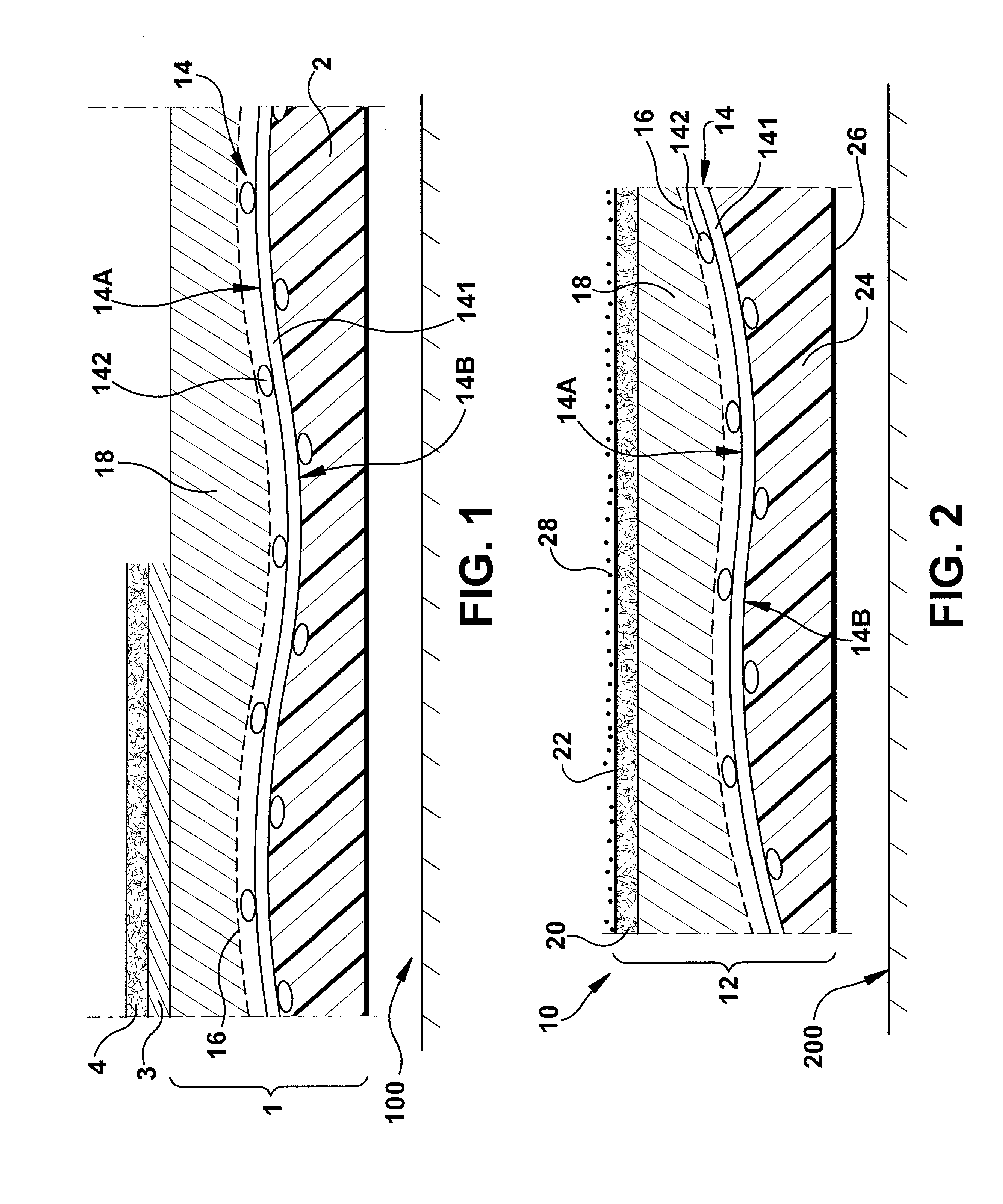

[0020]The present disclosure and related inventions are directed to waterproof membranes and particularly to single-ply polymeric coated substrates which serve as the primary water barrier in a waterproof membrane. The single-ply polymeric coated substrates of the present disclosure and related inventions are combinable with one or more adhesives and additional materials to form a waterproof membrane for a wide variety of applications, including architectural and construction applications above and below grade and adjacent any surface or structure to be protected from moisture.

[0021]The present disclosure and related inventions also include improved substrates which serve as the waterproof barrier and structural puncture-resistant barrier for a single-layer roofing membrane. The waterproof membranes of the present disclosure, made with a single-ply polymer coated substrate as described herein, provide reduced weight and / or thickness; reduced cost; improved puncture resistance; impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com