Heat Treated Precipitated Silica

a technology of precipitated silica and heat treatment, which is applied in the direction of chemistry apparatus and processes, silicon oxides, and silicon compounds, can solve problems such as present compatibility problems with key formula actives, and achieve the effects of reducing plaque, sensitivity, and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

Heat Treated Precipitated Silica

[0136]Samples of commercially available precipitated silica materials were heat treated for times and temperatures as shown below in Table 1.

TABLE 1Material% StannousZ-10961.0Z-109 - 2 hrs @ 600° C.85.0Z-11942Z-119 - 2 hrs @ 600° C.75.5Z-119 - 1 min @ 900° C.74.0

Z-109 and Z-119 are precipitated silicas commercially available from the Huber Corporation (USA). As may be seen in Table 1, treatment of a precipitated silica, Z-119, for about 1 minute at 900° improved the compatibility with stannous (the percentage of stannous ion available over time) at nearly the same level as by treating the same material for two hours at 600° C. The present invention therefore provides a similar benefit at a significant lower energy cost.

example ii

Heat Treated Precipitated Silica

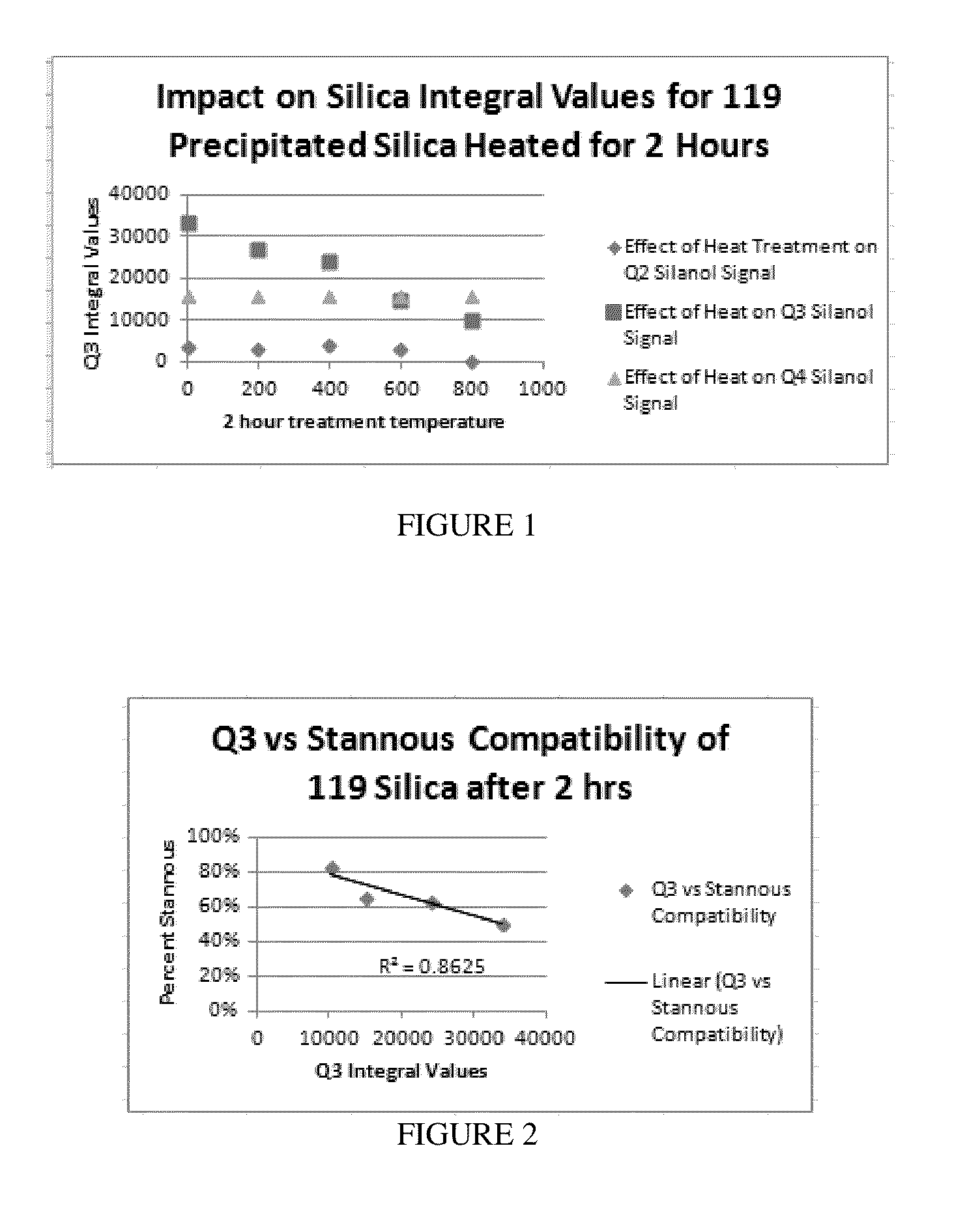

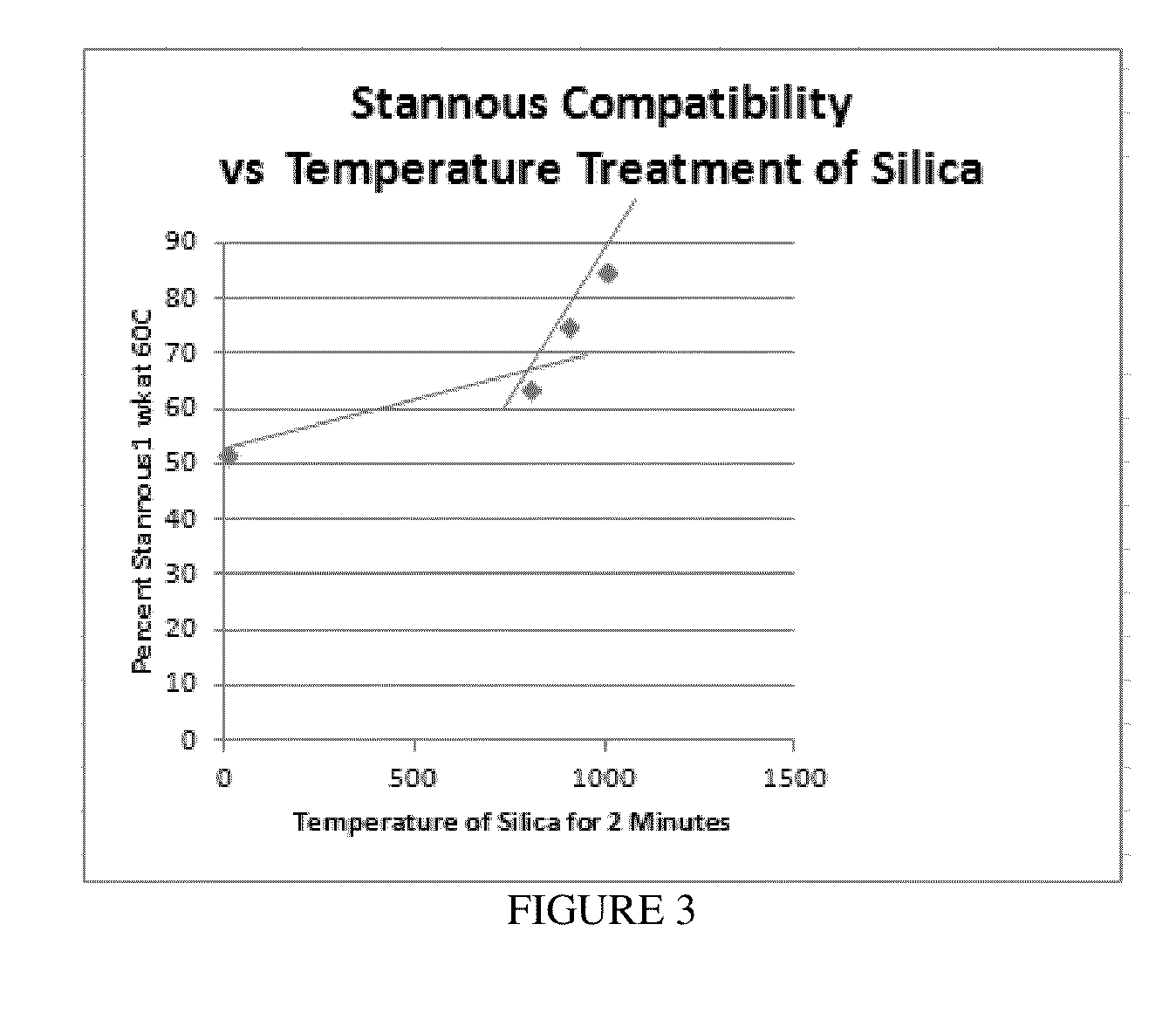

[0137]Samples of commercially available precipitated silica materials were heat treated for times and temperatures as shown below in Table 2. NMR was then used to determine the level of Q2, Q3 and Q4 silanols with the readings normalized to Q4. Compatibility with stannous in a stannous-silica slurry was then measured by determining the amount of stannous ion available in the slurry after one week at 60° C. The results are tabulated below, also in Table 2.

TABLE 2Q4 NormalizedTemp.SnValues (%)*Q4 Normalized Integral Values**SilicaTime(° C.)(%)Q2Q3Q4Q2Q3Q4TotalZ-119NoneNone517.2862.5430.183948339031636254213Z-1192 hrs.2007.4557.934.653517273391636247218Z-1192 hrs.4006410.5253.3936.094768242041636245335Z-1192 hrs.600669.6743.1447.193352149581636234673Z-1192 hrs.800831.8537.5560.60499101371636226998Z-119NoneNone52Z-1192 min.80064.213.8944.741.415489176661636239517Z-1192 min.90075.513.3150.0336.675938223241636244624Z-1192 min.1000 80-9013.3646.8839.77549519...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com