Acoustic structure with internal thermal regulators

a technology of internal thermal regulator and acoustic structure, which is applied in the direction of liquid fuel engines, instruments, machines/engines, etc., can solve the problems of affecting the service life of a typical heat blanket, and affecting the service life of the typical heat blank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

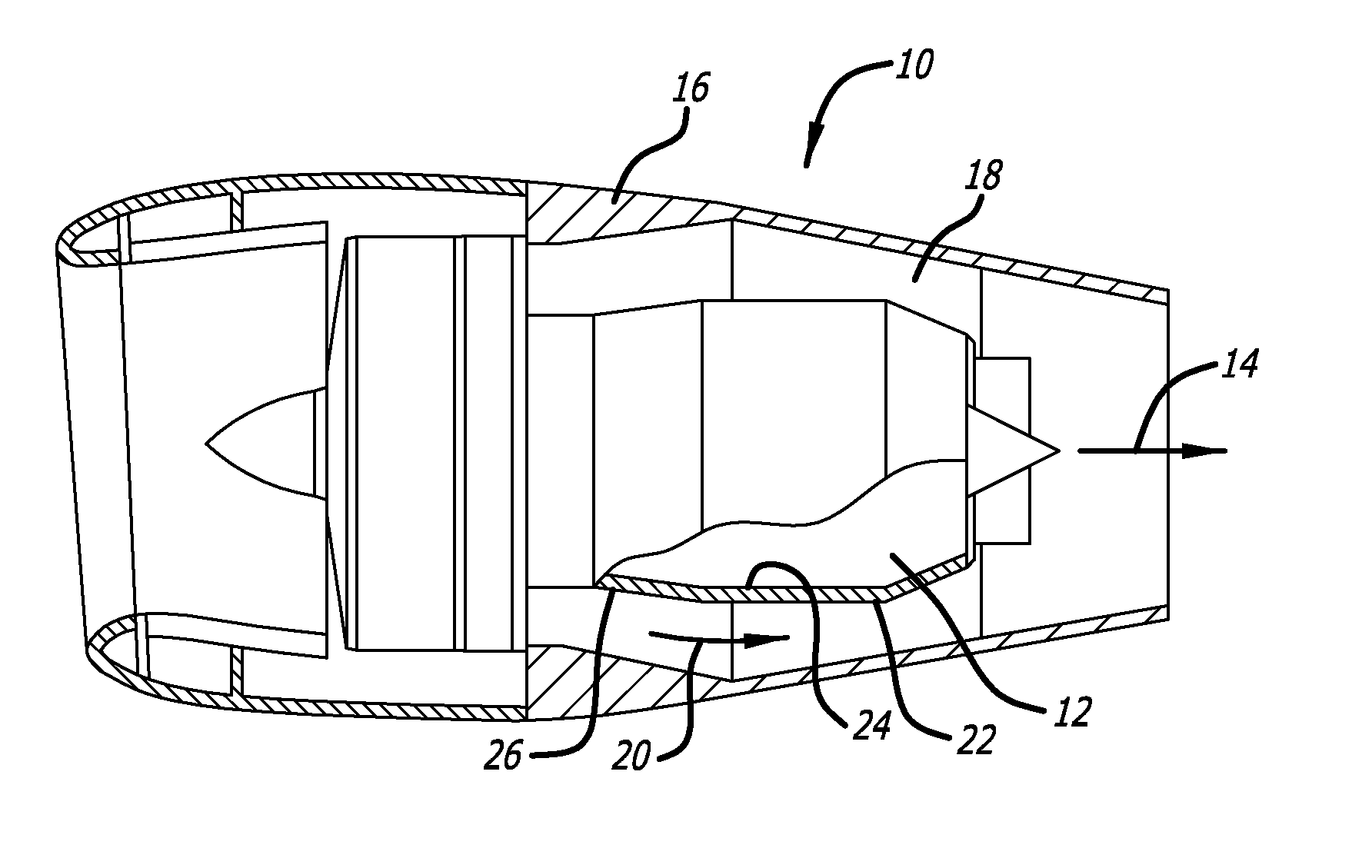

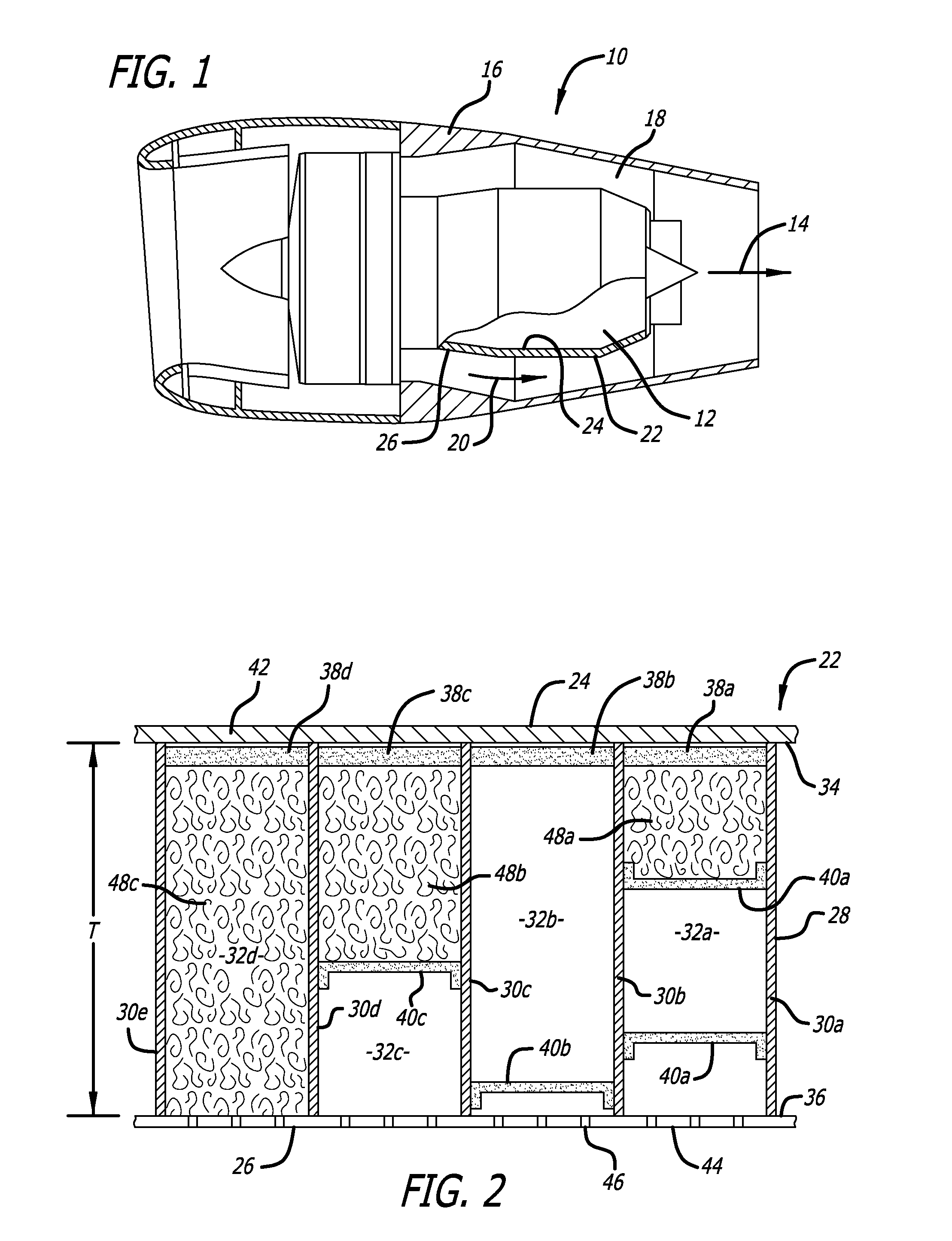

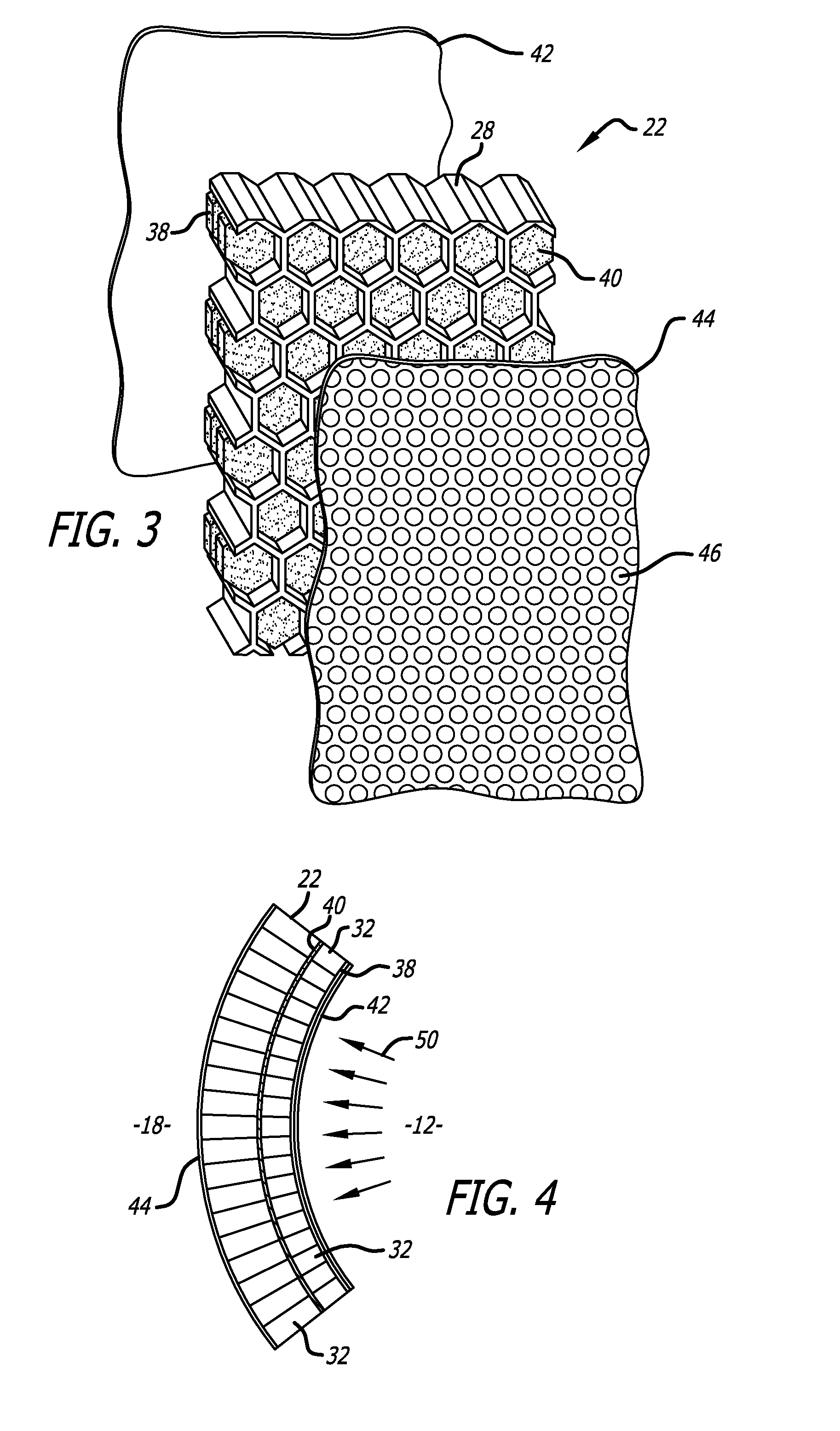

[0023]The acoustic structure of the present invention may be used for damping noise from a wide variety of noise sources where the acoustic structure is exposed on one side to elevated temperatures. The acoustic structure is well-suited for use in damping noise generated by aircraft engines and particularly the large jet engines used for commercial aircraft. The acoustic structure includes internal thermal regulators so that it may be employed, without a heat blanket or other external thermally insulating structure, at locations within current engine designs which operate at maximum temperatures on the order of the 600° F. to 750° F. A preferred acoustic structure in accordance with the present invention includes a heat blanket or other external thermally insulating structure in order to meet the increased thermal load produced by the next generation large jet engines. The next generation of large jet engines will operate in some hot sections at temperatures up to 900° F. and higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com