Supply vessel

a technology for supply vessels and water tanks, applied in waterborne vessels, tugs, vessel construction, etc., to achieve the effect of low deadweight of supply vessels and high transfer speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0032]In the first embodiment the supply vessel has the following main particulars:

Length overall22.00 mBreadth12.00 mDepth to upper deck 4.50 mDraught (free sailing) 2.00 m

[0033]The deadweight at summer draught may be at about 35 t.

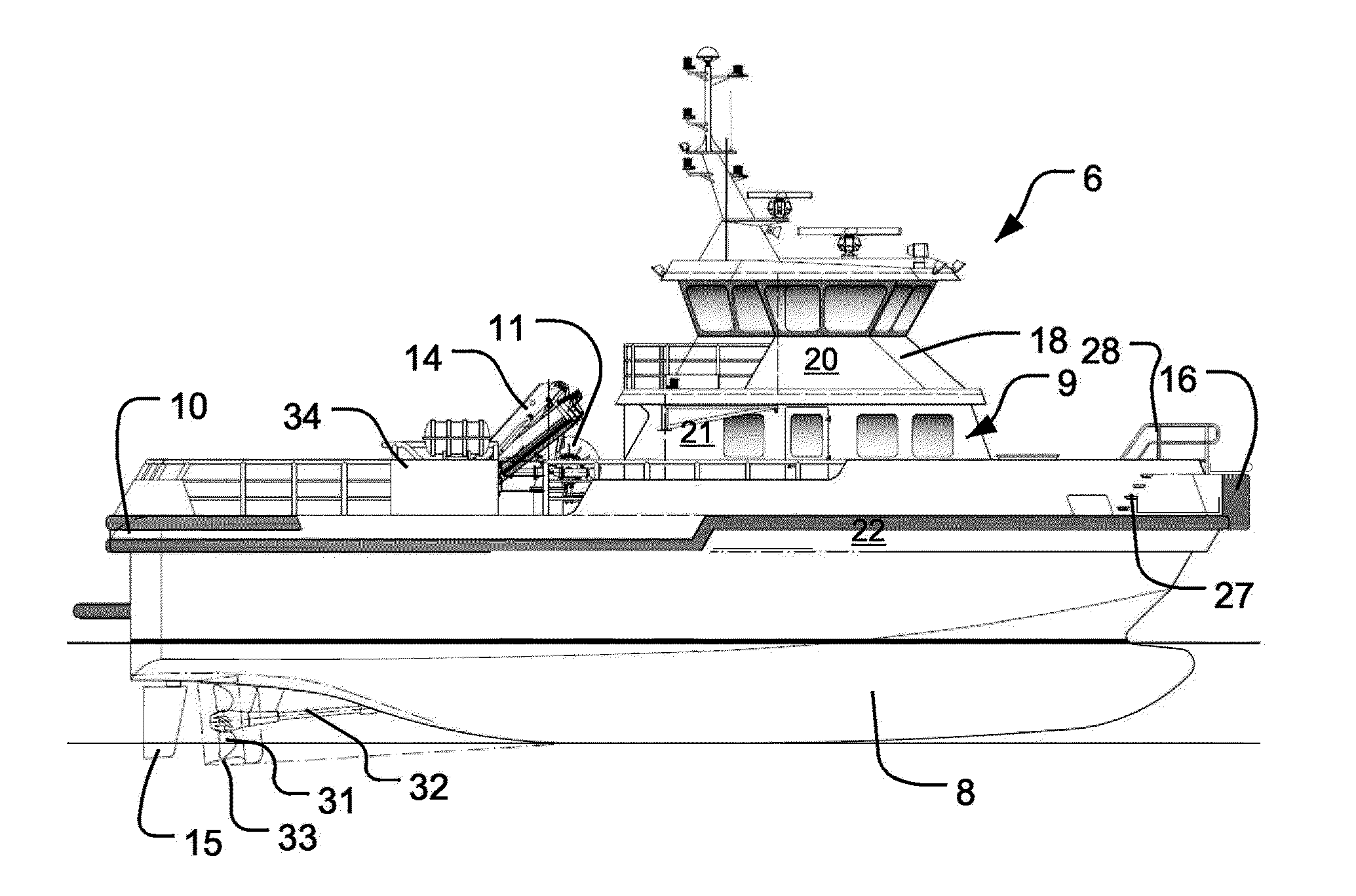

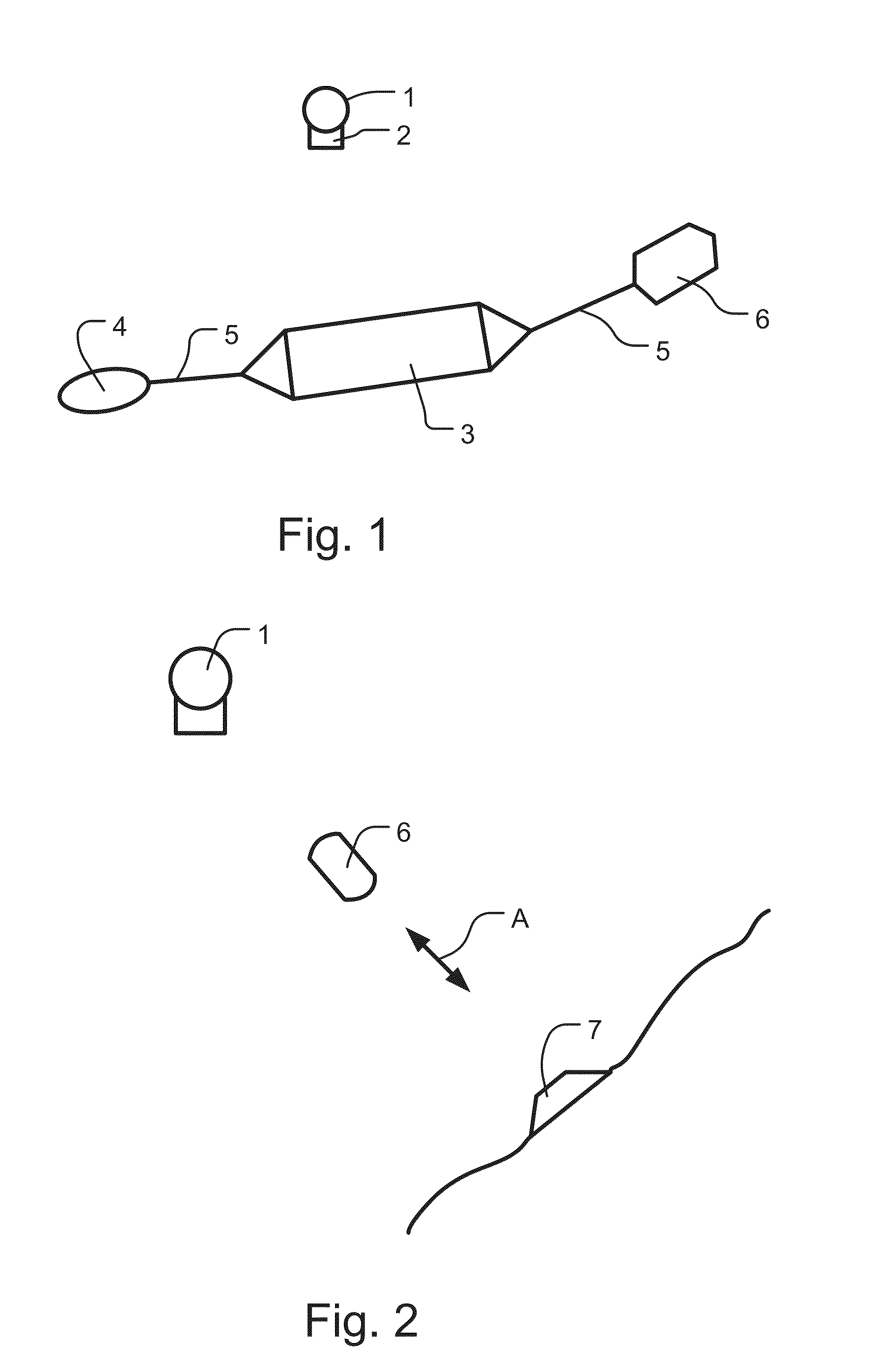

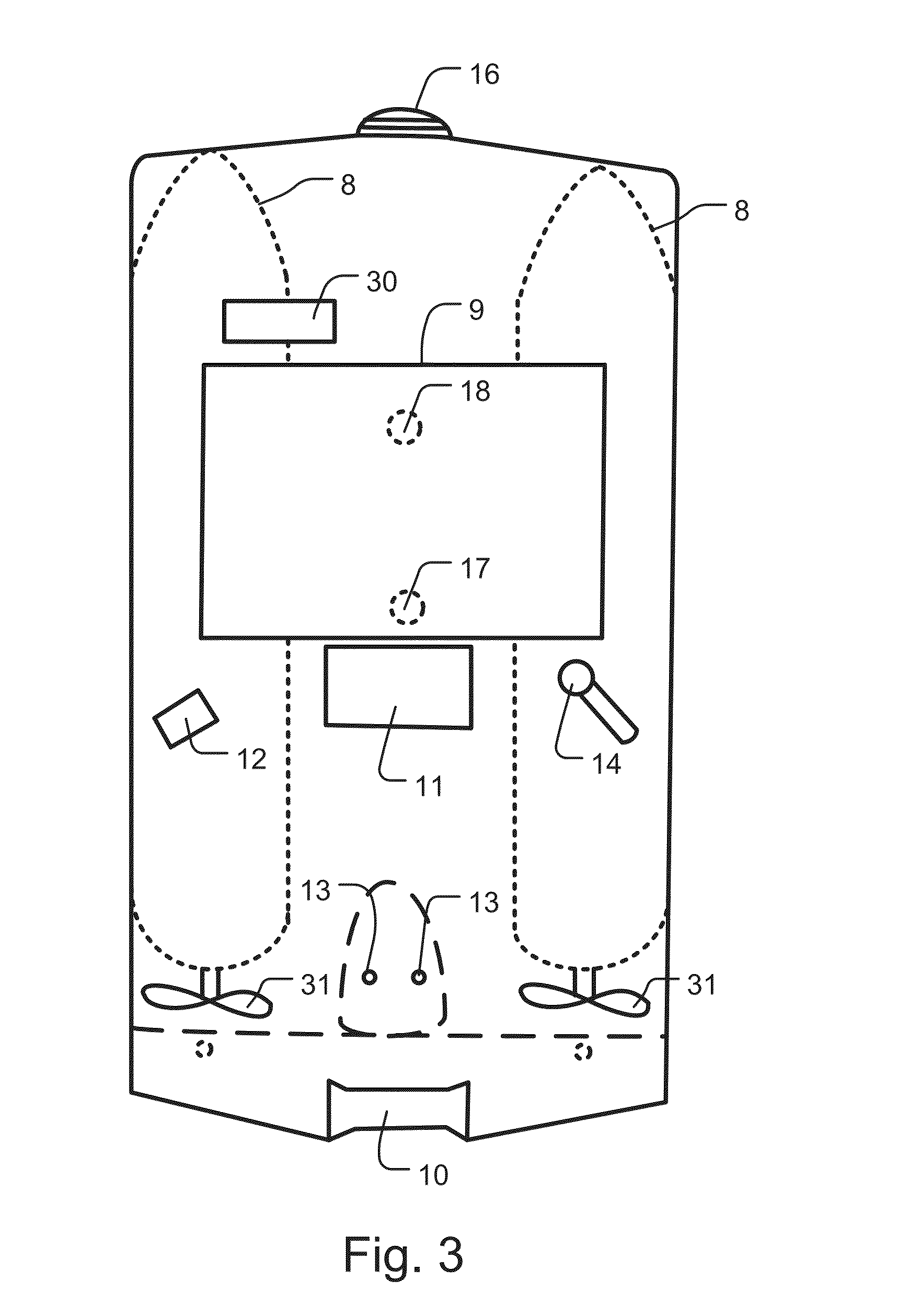

[0034]The supply vessel has two hull sections 8 interconnected by a deck structure 22 and a deckhouse 9. The deckhouse has a lower part 21 with a passenger main saloon provided with a plurality of passenger chairs, such as 12 chairs. Next to the saloon the deckhouse has a lavatory, and the saloon may be provided with galley corner with dishwasher and cooking facilities. In an upper part 20 the deckhouse is provided with a bridge having at least a forward 18 and an aft 17 maneuvering position with skipper chairs, echo sounder, vhf radios and radar or other navigational and safety equipment.

[0035]In the bow the supply vessel is provided with a fender 16 at the middle of the bow. The aft deck has a tug layout. A towing winch 11 is located just aft of the de...

second embodiment

[0043]In the second embodiment the supply vessel has the following main particulars:

Length overall23 mBreadth12 mDepth to upper deck4.50 mSpeedabove 20 knotsBollard pull25 tTowing winch30 tTugger winch3 tPassengers12Crew4Propulsion engines2 × 1100 hp

[0044]A propulsion engine 29 is arranged in each hull section 8, and via a propeller shaft 32 the propeller 31 is driven by the engine. The propeller may have adjustable pitch, and is located in a propeller nozzle 33. Each engine room is provided with ventilation air through air intakes 34 and 35. Each engine can deliver a power of 1100 hp.

[0045]The stern roller 10 located in a central location aft of the towing winch can be a fixed curved surface in the hull of the vessel, which curved surface allows the chains, wires or other equipment handled by the tugger winch and the towing winch to roll over and along the surface when entering or leaving the vessel. The stern roller can also be a circular cylindrical body mounted at the stern with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com