Solar cells having graded doped regions and methods of making solar cells having graded doped regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

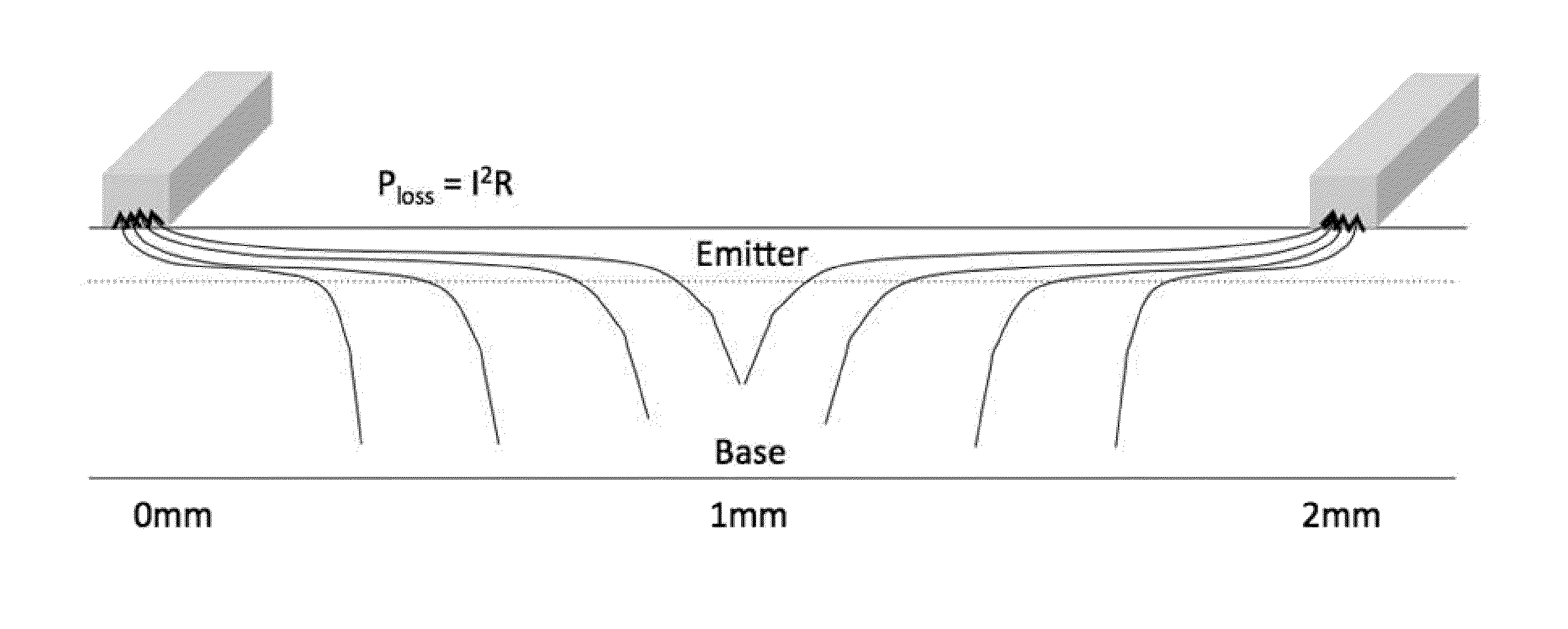

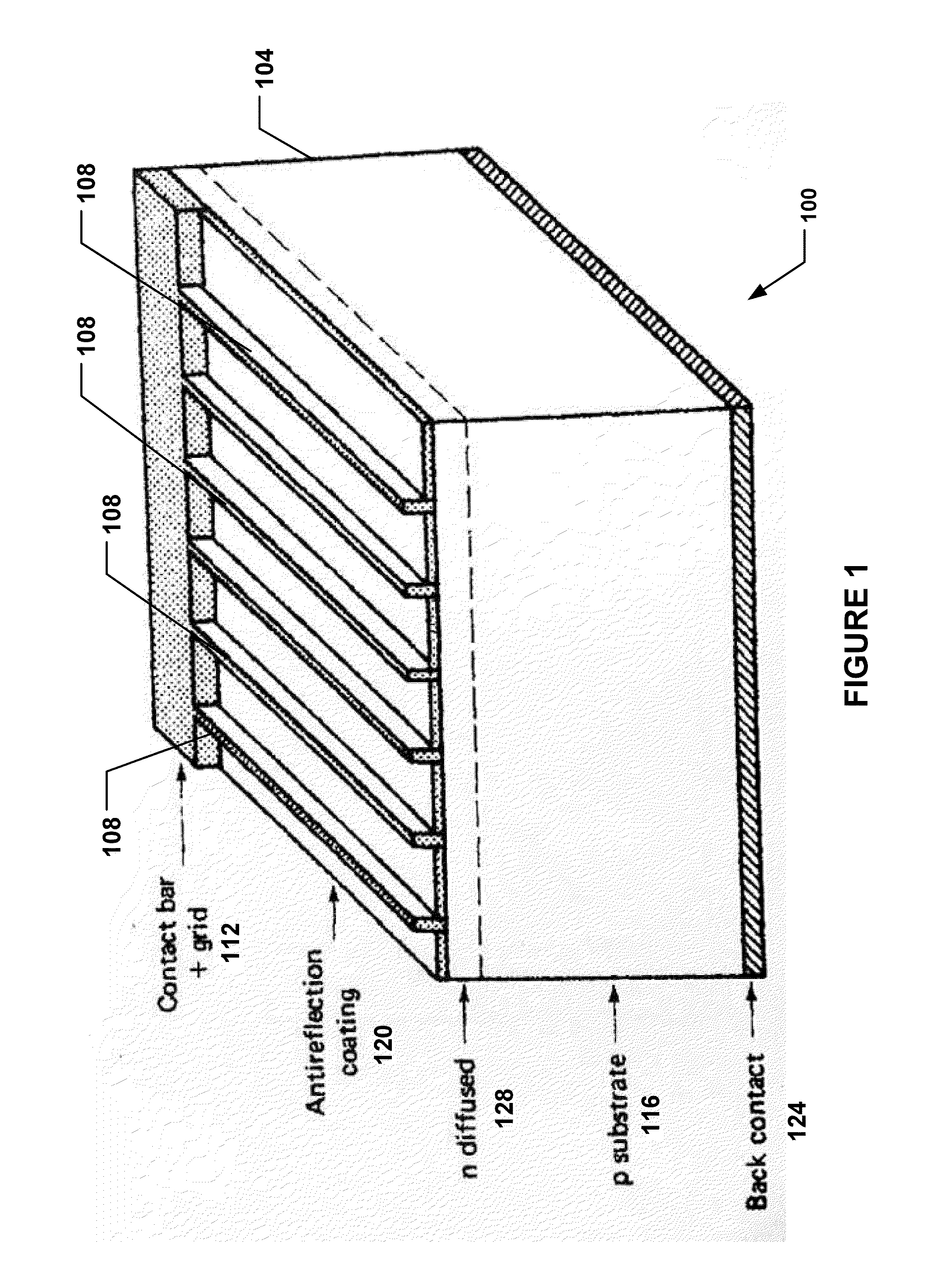

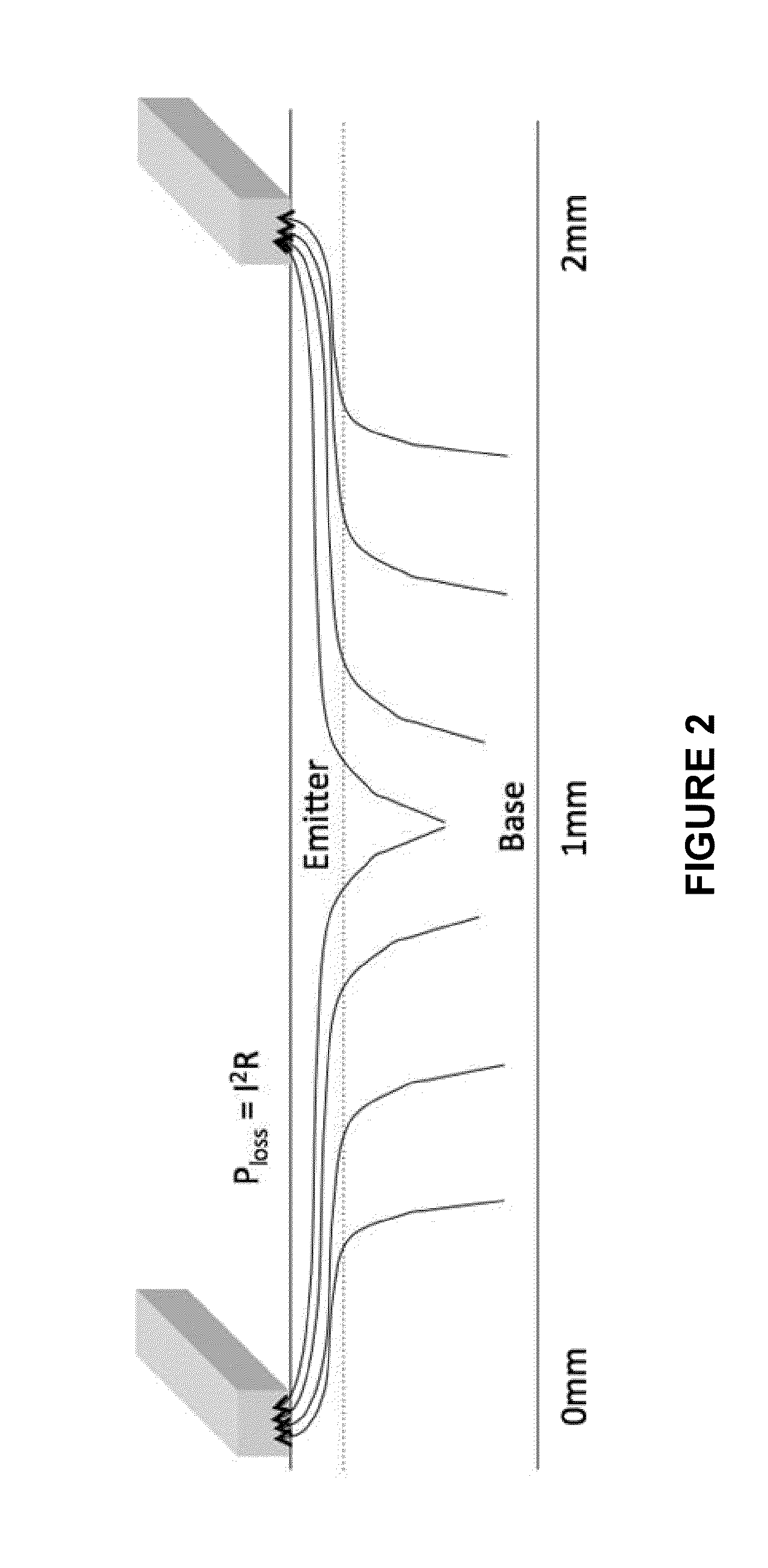

[0034]Embodiments of the invention are directed to photovoltaic (solar) cells having graded doping regions, such as graded emitters. Since the power loss is not uniform across the graded doping region, a more optimal solution to reduce the power loss described above is to decrease the sheet resistance in the regions of highest current.

[0035]Graded doping lowers the sheet resistance in the regions of highest current in proportion to the I2R losses. Graded doping can be used in any region that collects current and / or experiences current crowding. Embodiments of the invention are also directed to graded back surface fields or graded doping for base contacts. Graded emitters or other graded doping regions are formed by grading the dopant concentration. Sheet resistance is generally proportional to doping concentration. The dopant profile of the graded doping region can be selected so that there is a lower sheet resistance near the metal contacts and a higher sheet resistance at a furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com