Highly soluble stevia sweetener

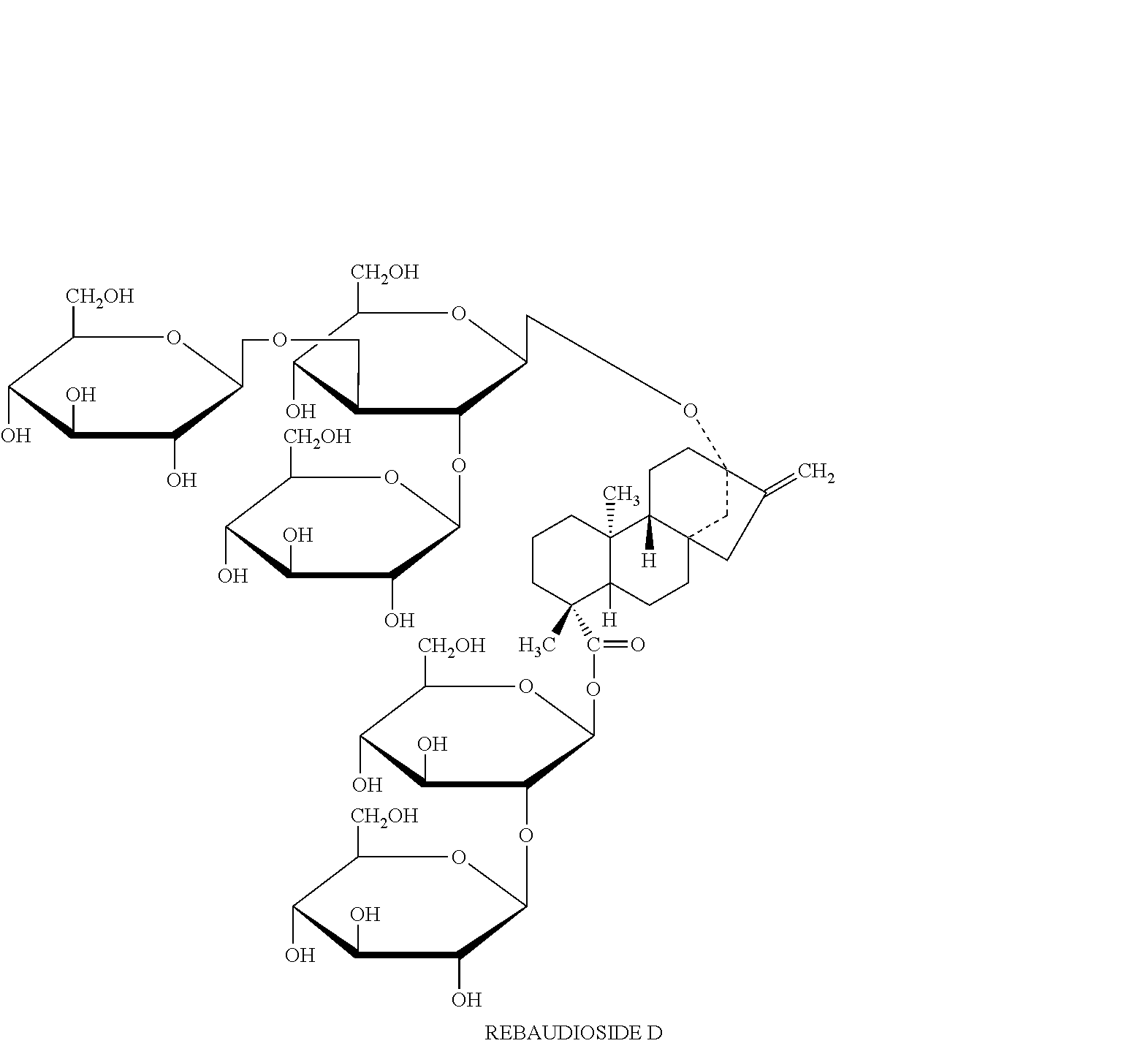

a sweetener and stevia technology, applied in the field of highly soluble sweet glycosides, can solve the problems of inability to use heat for dissolving reb d in compositions containing heat sensitive components, undesirable changes in organoleptic properties, and thermal degradation of mixture components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Reb D Concentrated Solution

[0036]100 g of rebaudioside D produced by PureCircle Sdn Bhd (Malaysia), with 98.1% purity (dry weight basis), having water solubility of 0.03% at room temperature was mixed with 400 g of water and incubated in thermostatted oil bath. The temperature was increased at 1° C. per minute to 121° C. The mixture was maintained at 121° C. for 1 hour and then the temperature was decreased to 80° C., at 1° C. per minute to make Solution#1.

example 2

Preparation of Reb D and Reb A Concentrated Solution

[0037]70 g of rebaudioside D with 98.1% purity (dry weight basis), having water solubility of 0.03% and 30 g of rebaudioside A with 98.6% purity (dry weight basis), and having water solubility of 5.5%, both produced by PureCircle Sdn Bhd (Malaysia), were mixed with 400 g water and subjected to heat treatment as described in EXAMPLE 1 to make Solution#2.

example 3

Preparation of Reb D and Reb B Concentrated Solution

[0038]70 g of rebaudioside D with 98.1% purity (dry weight basis), having water solubility of 0.03% and 30 g of rebaudioside B with 99.0% purity (dry weight basis), and having water solubility of 0.01%, both produced by PureCircle Sdn Bhd (Malaysia), were mixed with 400g water and subjected to heat treatment as described in EXAMPLE 1 to make Solution#3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com