Ink jet recording method and recorded matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

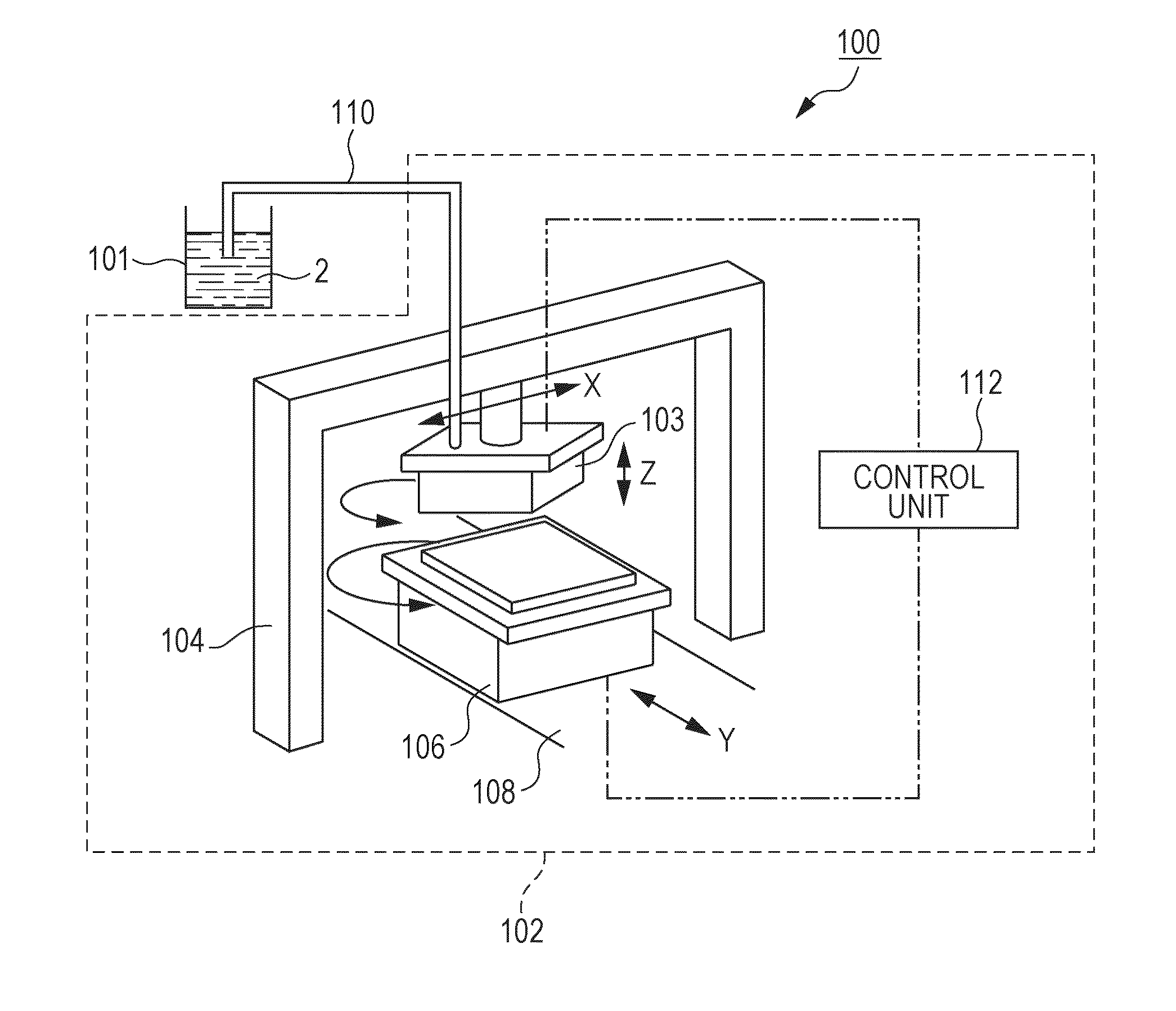

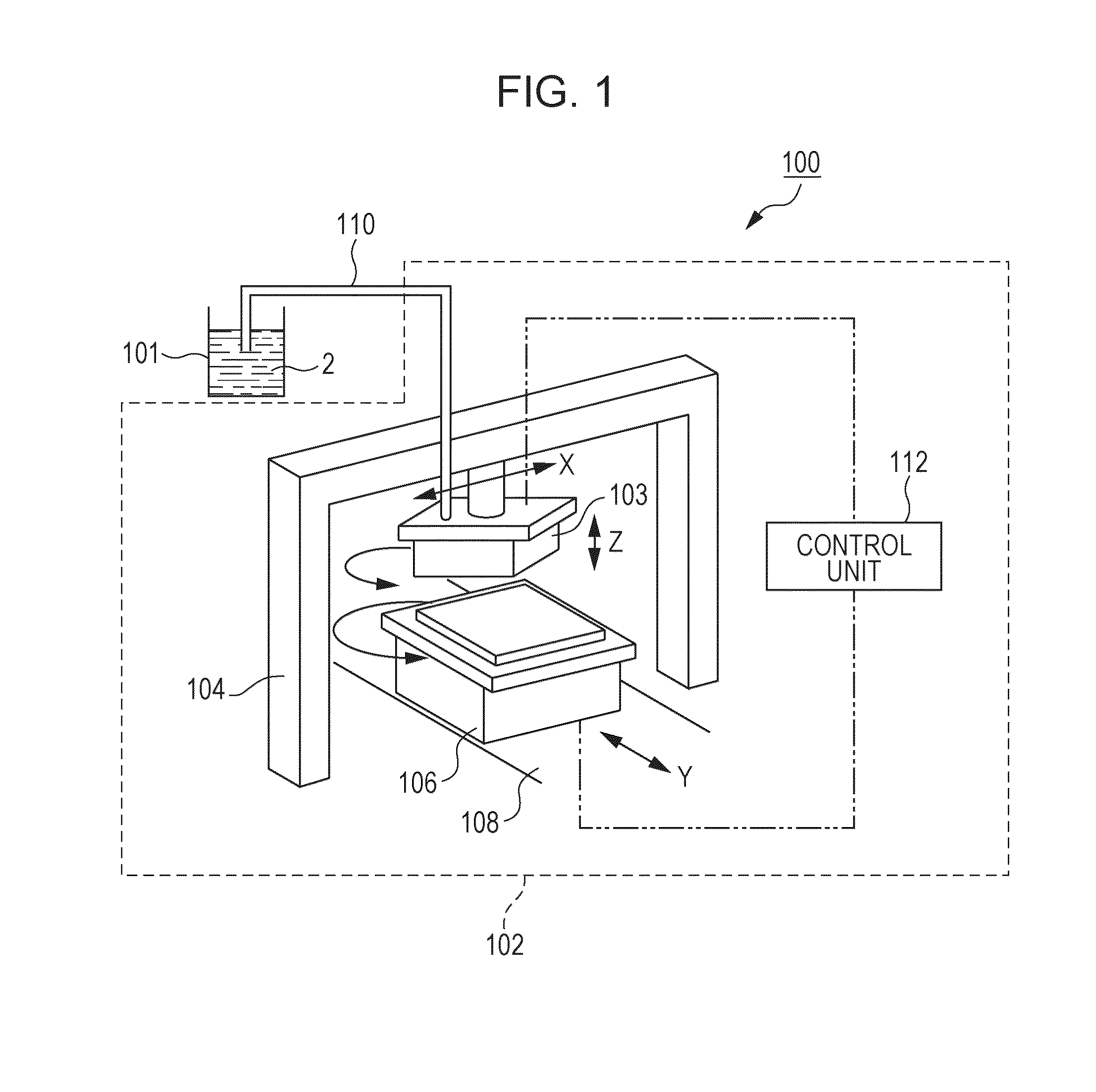

Method used

Image

Examples

example 1

[0142]First, the ink composition (first ink composition) is prepared as below.

[0143]Water, C.I. Pigment Blue 15:3 (average particle size: 100 nm) as a resin dispersed pigment, resin particles (glass transition point: 20° C., average particle size: 100 nm) configured by a styrene-acrylic copolymer, 1,2-hexanediol as the alkane diol with 4 or more to 8 or fewer carbon atoms, glycerin, and triethanolamine as amine derivative were mixed, and an ink composition (first ink composition) was obtained.

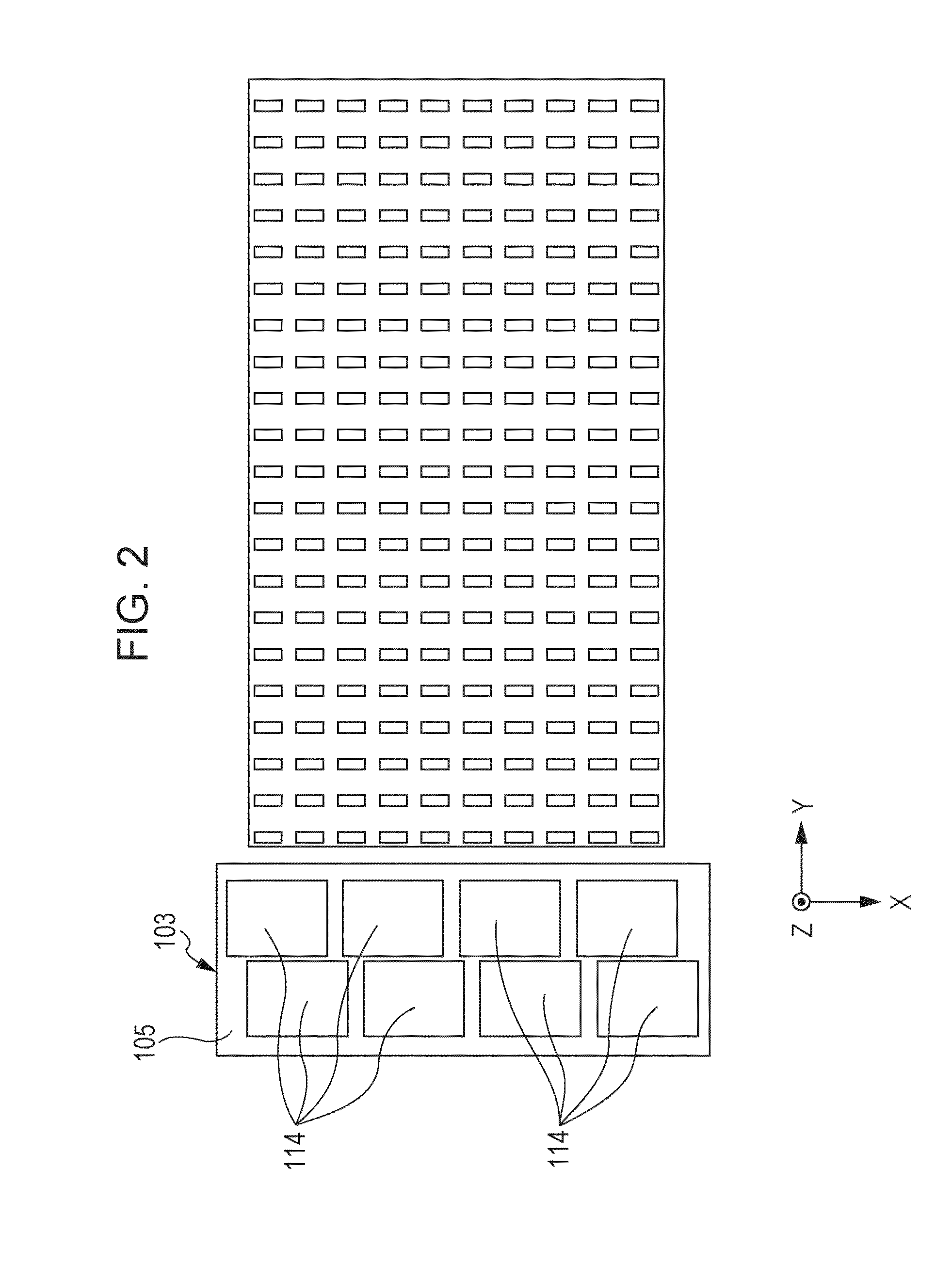

[0144]Next, the ink composition (first ink composition) prepared as above was filled in the interior of a discharge head (resolution per unit length: 360 dpi) using a piezoelectric element attached to an ink jet recording method printer PX-G930 (manufactured by Seiko Epson). After filling, the ink composition is applied with respect to the recording medium described in Table in a predetermined pattern, and a recorded matter is obtained.

[0145]Moreover, the recording medium A below is used as the...

examples 2 to 10

[0147]By adjusting the type and usage amount of the components used in the preparation of the ink composition, the constitutions shown in Table were prepared and further, other the using the recording medium shown in Table, a recorded matter was manufactured similarly to Example 1.

[0148]Moreover, recording medium B is a film-based matte paper (MC Matte Synthetic Paper, manufactured by Seiko Epson) including an absorbing layer, the nonpolar component γsd of the surface free energy is 19.6 mN / m, and the polar component γsp of the surface free energy exceeds 20 mN / m.

[0149]Recording medium C is a recording paper (Xerox 4200, manufactured by Xerox), the nonpolar component γsd of the surface free energy is 26.3 mN / m, and the polar component γsp of the surface free energy is 0.3 mN / m.

[0150]Recording medium D is a recording paper (Xerox P, manufactured by Xerox), the nonpolar component γsd of the surface free energy is 38.2 mN / m, and the polar component γsp of the surface free energy is 3.7...

example 11

[0152]In Example 11, the ink composition disclosed in Example 1 was used as the first ink composition, and furthermore, outside of use together with the ink composition disclosed in Example 4 as the second ink composition, a recorded matter was prepared similarly to Example 1.

Comparative Examples 1 to 4, Reference Examples 1 and 2

[0153]Other than using the ink composition and recording medium as shown in Table, the recorded matter is manufactured in the same manner as Example 1.

[0154]Moreover, in the table, C.I. Pigment Blue 15:3 is represented by “PB15:3” and carbon black by “CB”, an styrene-acrylic copolymer by “St-Ac”, 1,2-hexanediol as an alkane diol with 4 or more to 8 or fewer carbon atoms by “1,2-HD”, 1,2-pentanediol by “1,2-PD”, the alkylene glycol alkyl ether in formula (2) for which R1 is an n-butyl group, R2 is a hydrogen atom, n is 3, and k is 0 by “GE1”, the alkylene glycol alkyl ether of formula (2) for which R1 is a methyl group, R2 is a methyl group, n is 1, and k is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com