Wiring film and active matrix substrate using the same, and method for manufacturing wiring film

a technology of active matrix substrate and wiring film, which is applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of reducing the breakdown voltage of the insulating film, the inclination of the sidewall of the tapered al wiring film acutely changes accordingly, and the film has poor step coverage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

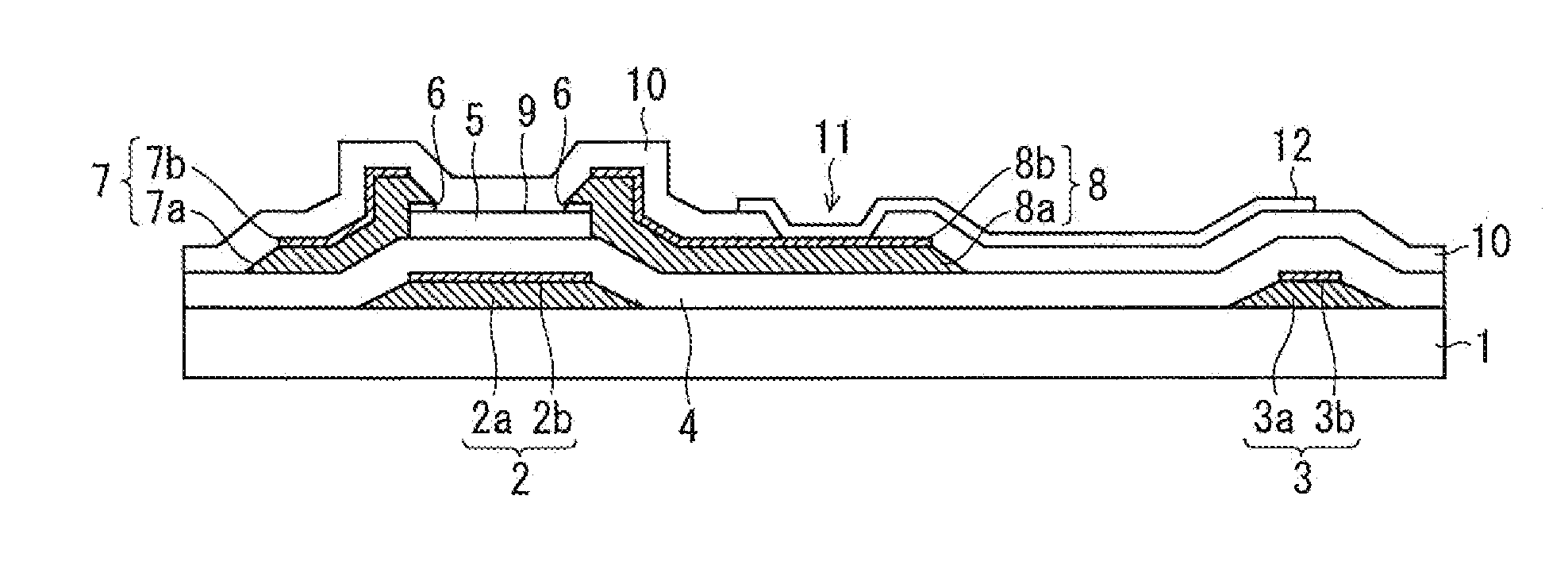

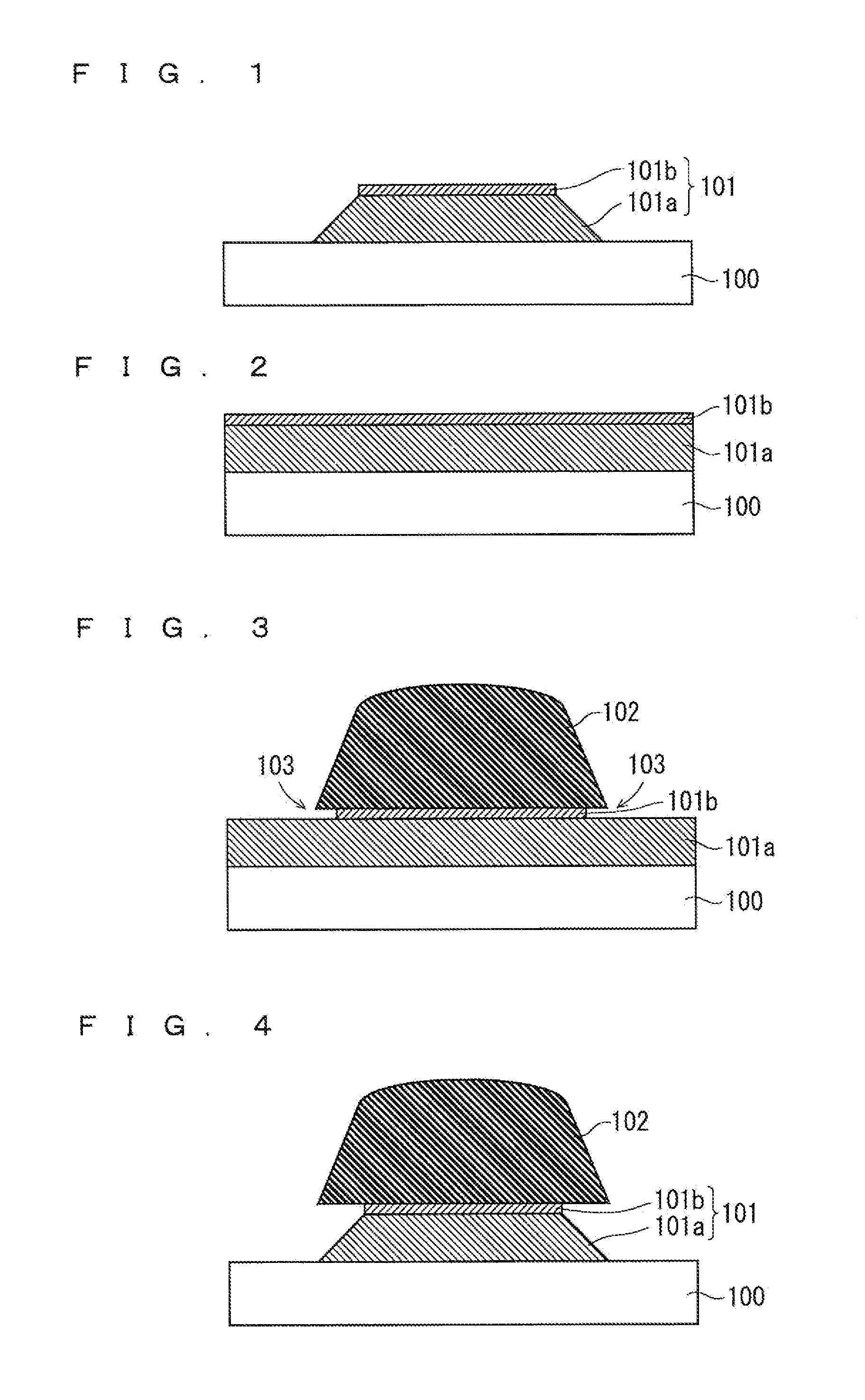

[0025]FIG. 1 is a cross sectional view of a structure of an Al wiring film according to a first preferred embodiment. As illustrated in FIG. 1, an Al wiring film 101 formed on a substrate 100 according to this preferred embodiment has a double-layer structure including a first Al alloy layer 101a and a second Al alloy layer 101b formed thereon, and has a tapered shape in cross section with a width smaller in an upper portion thereof than a width in a bottom portion thereof.

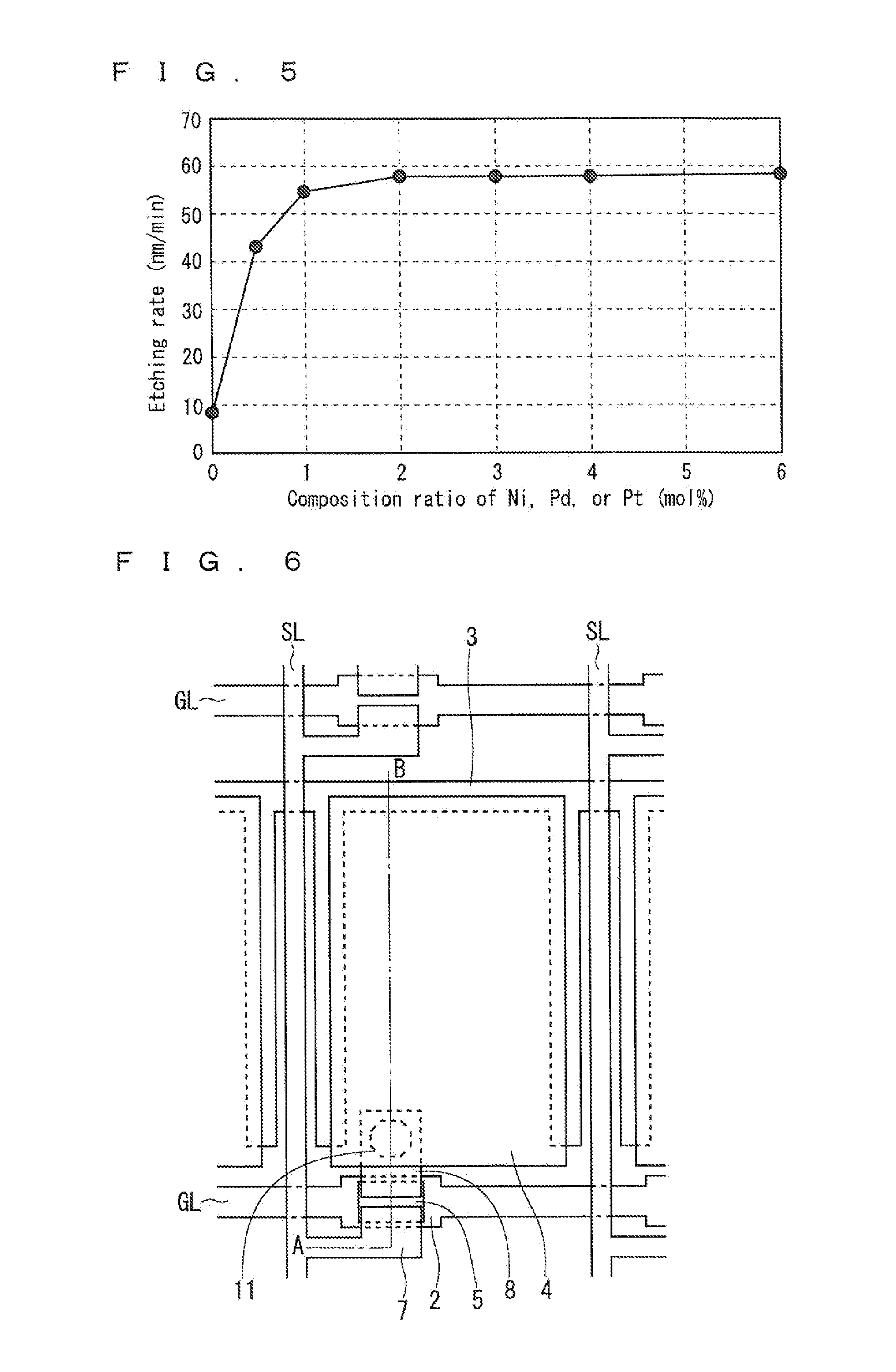

[0026]The first Al alloy layer 101a is a layer including Al as a main component. This is not restricted to the Al alloy, but pure Al may also be used. The second Al alloy layer 101b is made of an Al alloy containing at least one element of nickel (Ni), palladium (Pd), and platinum (Pt). The composition of the Al alloy of the first Al alloy layer 101a is different from the composition of the Al alloy of the second Al alloy layer 101b.

[0027]In addition, the substrate 100 serving as a base for the Al wiring film 101...

second preferred embodiment

[0066]FIG. 12 is a cross sectional view of a structure of an Al wiring film according to a second preferred embodiment. As illustrated in FIG. 12, an Al wiring film 201 formed on a substrate 100 according to this preferred embodiment has a triple-layer structure including a first Al alloy layer 201a, a second Al alloy layer 201b, and a third Al alloy layer 201c which are laminated in this order, and has a tapered shape in cross section with a width smaller in an upper portion thereof than a width in a bottom portion thereof.

[0067]The first Al alloy layer 201a is made of an Al alloy containing at least one element of Ni, Pd, and Pt. The second Al alloy layer 201b is made of an Al alloy containing nitrogen (N). The third Al alloy layer 201c is made of an Al alloy containing at least one element of Ni, Pd, and Pt. The first Al alloy layer 201a and the third Al alloy layer 201c may have an identical composition. Also, the second Al alloy layer 201b may be formed by adding nitrogen to an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com