Safety system for a traction kite with releasable adjustable bar stopper

a safety system and adjustable technology, applied in the direction of marine propulsion, special-purpose vessels, vessel construction, etc., can solve the problems of re-assembling the control system, carrying a high pulling load, and central load bearing line,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Best Mode

MODE FOR THE INVENTION

Mode for Invention

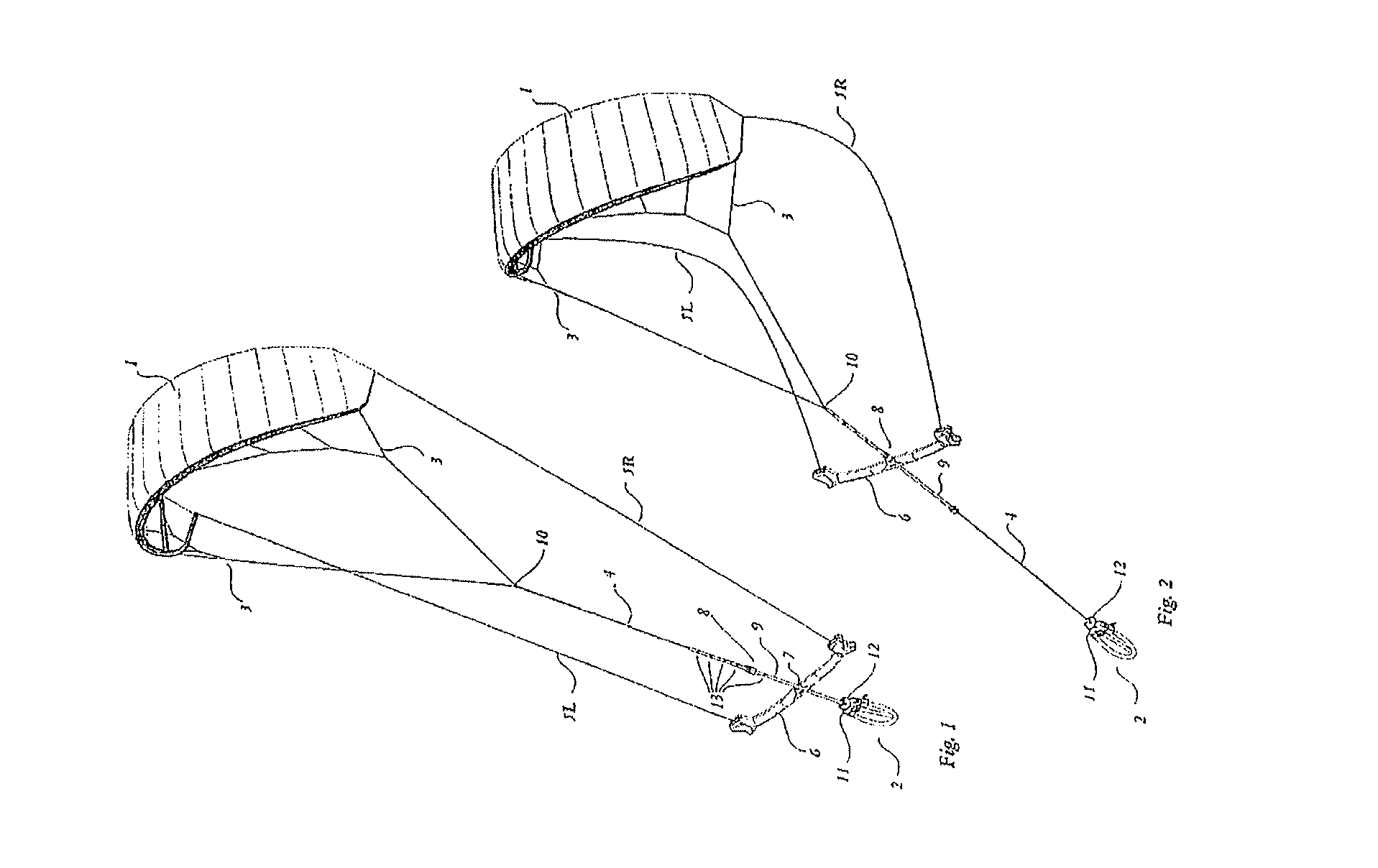

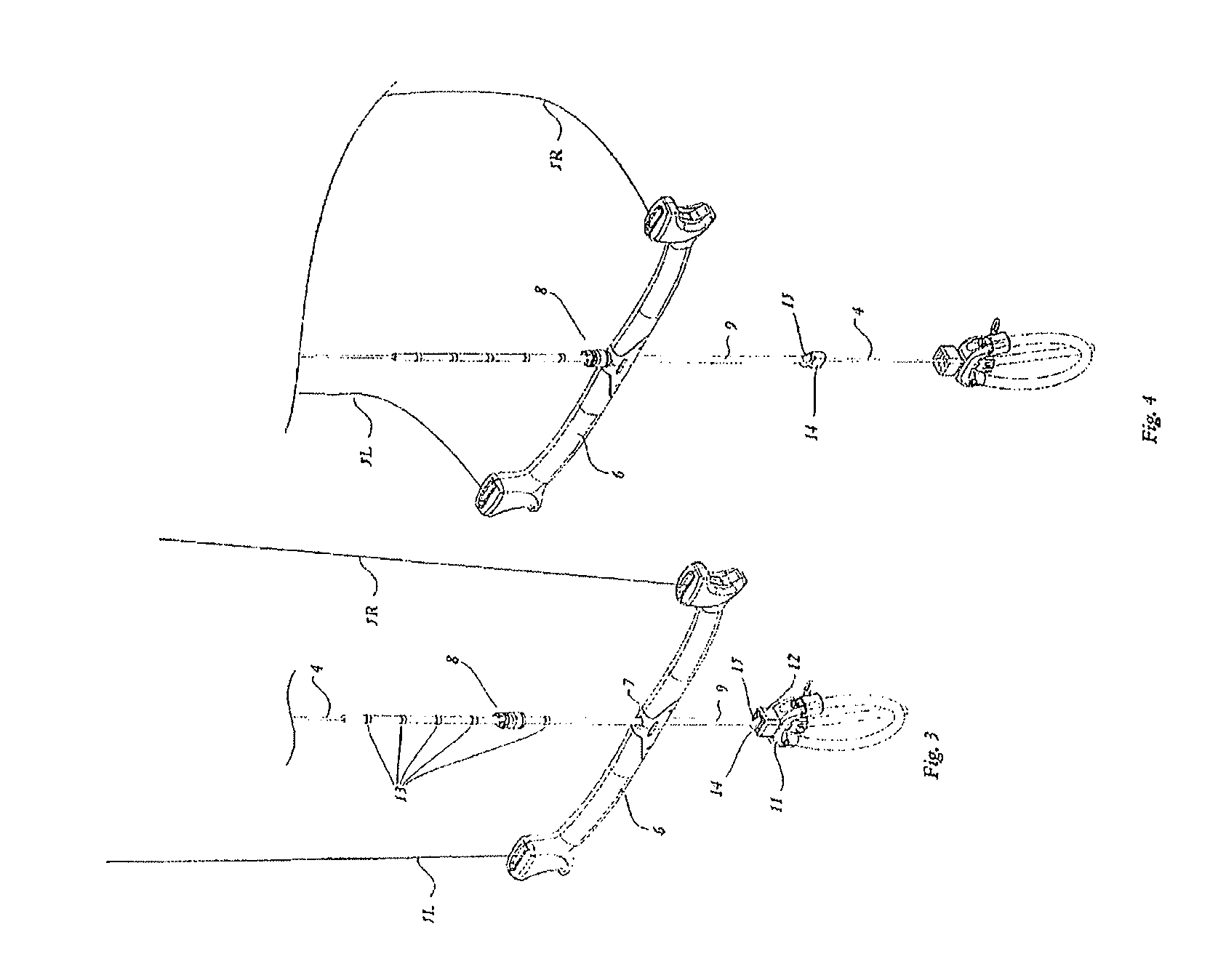

[0025]The present invention is further demonstrated by FIG. 1. A kite 1, with anchoring means 2, is provided with a typical 3-point control system which has multiple lines 3 attached to the forward edge which converge in to a central load bearing line 4 which attaches to the anchoring means 2, where the length of the lines 3 and central load bearing 4 together define length A, and two control lines SL and SR, attached to both ends of the trailing edge, each attached to one end a control bar 6. The bar is provided with a centrally placed hole 7 through which the central load bearing line can slide. A releasable adjustable bar stopper 8 according to the present invention is attached to a retaining means 9 and situated between the control bar 6 and a stopper ball 10. The retaining means attaches releasable to a system hub 11 of the anchoring means, provided with a release cuff 12. In general use, the flying kite is controlled by movement...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap