Brass alloy and method for manufacturing the same

a technology of brass alloy and manufacturing method, which is applied in the field of brass alloy, can solve the problems of easy dezincification corrosion phenomenon, easy dissolution in the form of solid or gas, and large damage to human hematopoietic and nervous systems, and achieve the effects of easy cutting, good dezincification resistance, and convenient tensile strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

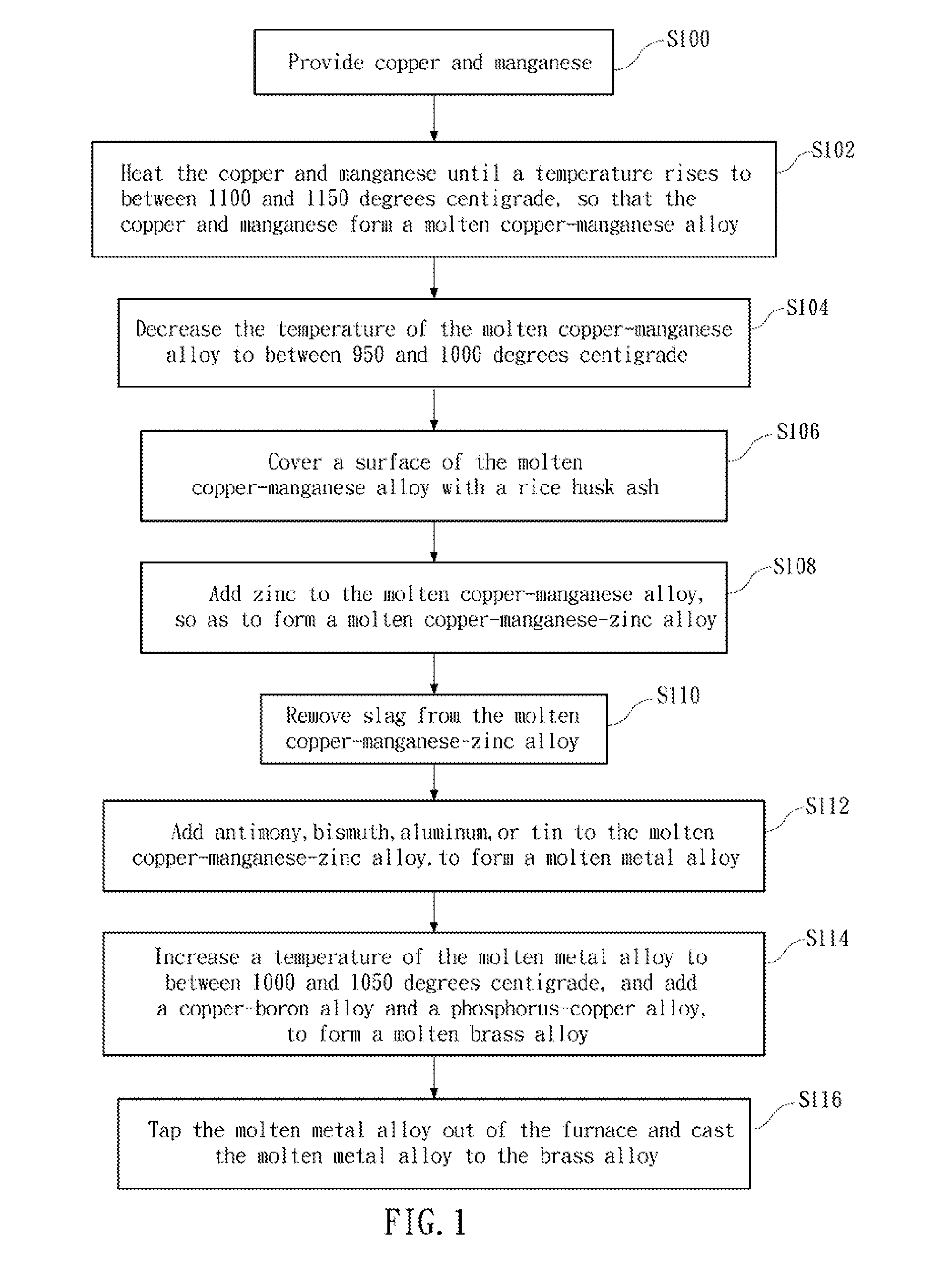

Method used

Image

Examples

Embodiment Construction

[0015]With a method for manufacturing a brass alloy according to an embodiment of the present invention, the brass alloy has machinability equivalent to that of a conventional leaded brass, desirable tensile strength and elongation, and good dezincification resistance, and does not contain lead, and therefore is a perfect alloy material to replace the conventional leaded brass to manufacture products. With its weight percentage counted as 100 wt %, the brass alloy includes the following elements: 60 wt % to 65 wt % of copper, 0.1 wt % to 0.35 wt % of bismuth, 0.15 wt % to 0.5 wt % of antimony, a balance of zinc, and an inevitable impurity. The brass alloy may further include one or a mixture of more than one selected from aluminum, tin, phosphorus, manganese, and boron, and total content of the selected mixture accounts for 0.2 wt % to 2 wt % of the brass alloy. In addition, during manufacturing, an inevitable impurity is brought into the brass alloy due to purity of a material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com