Passive way to improve heat distribution in packed bed storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

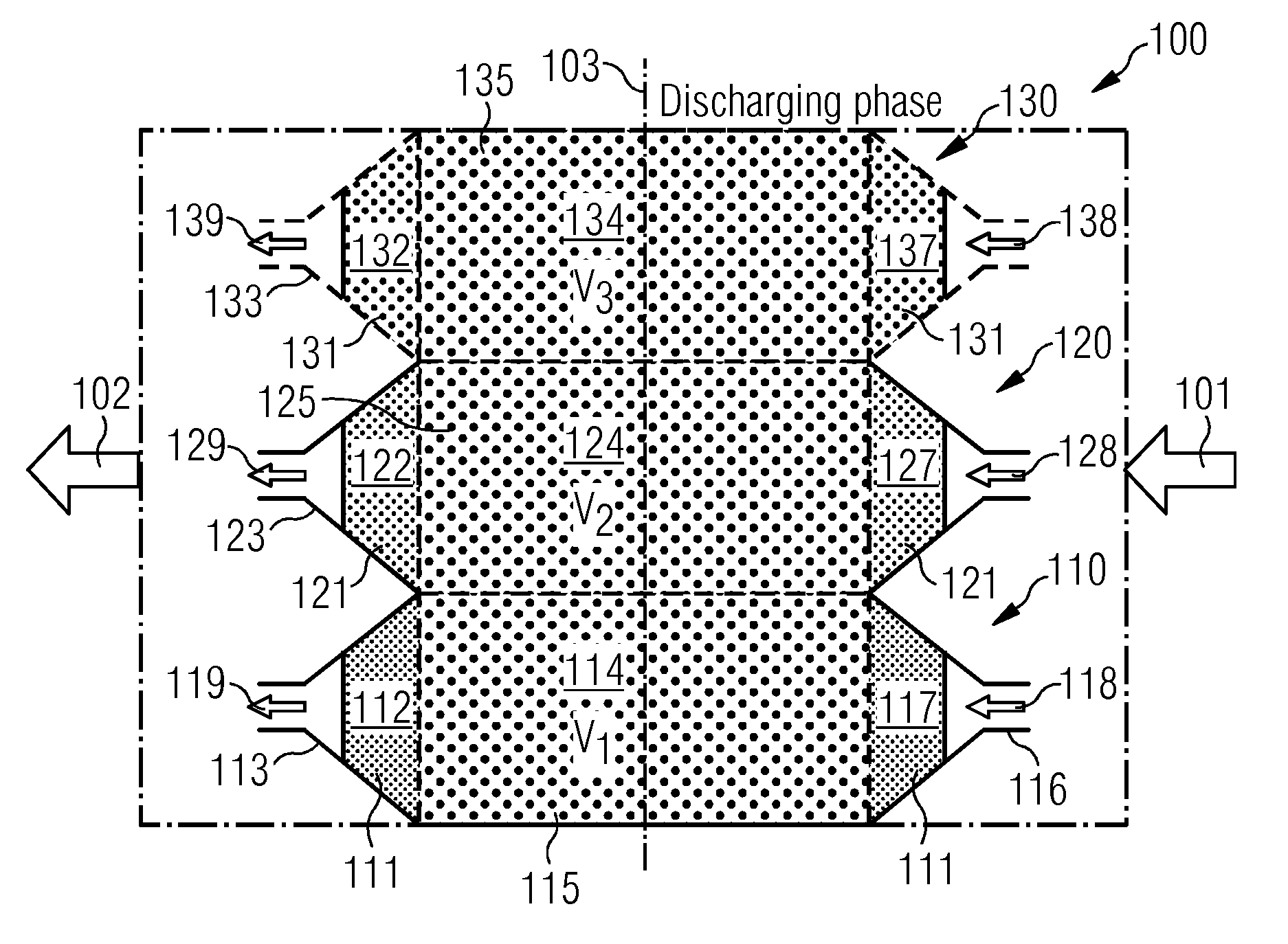

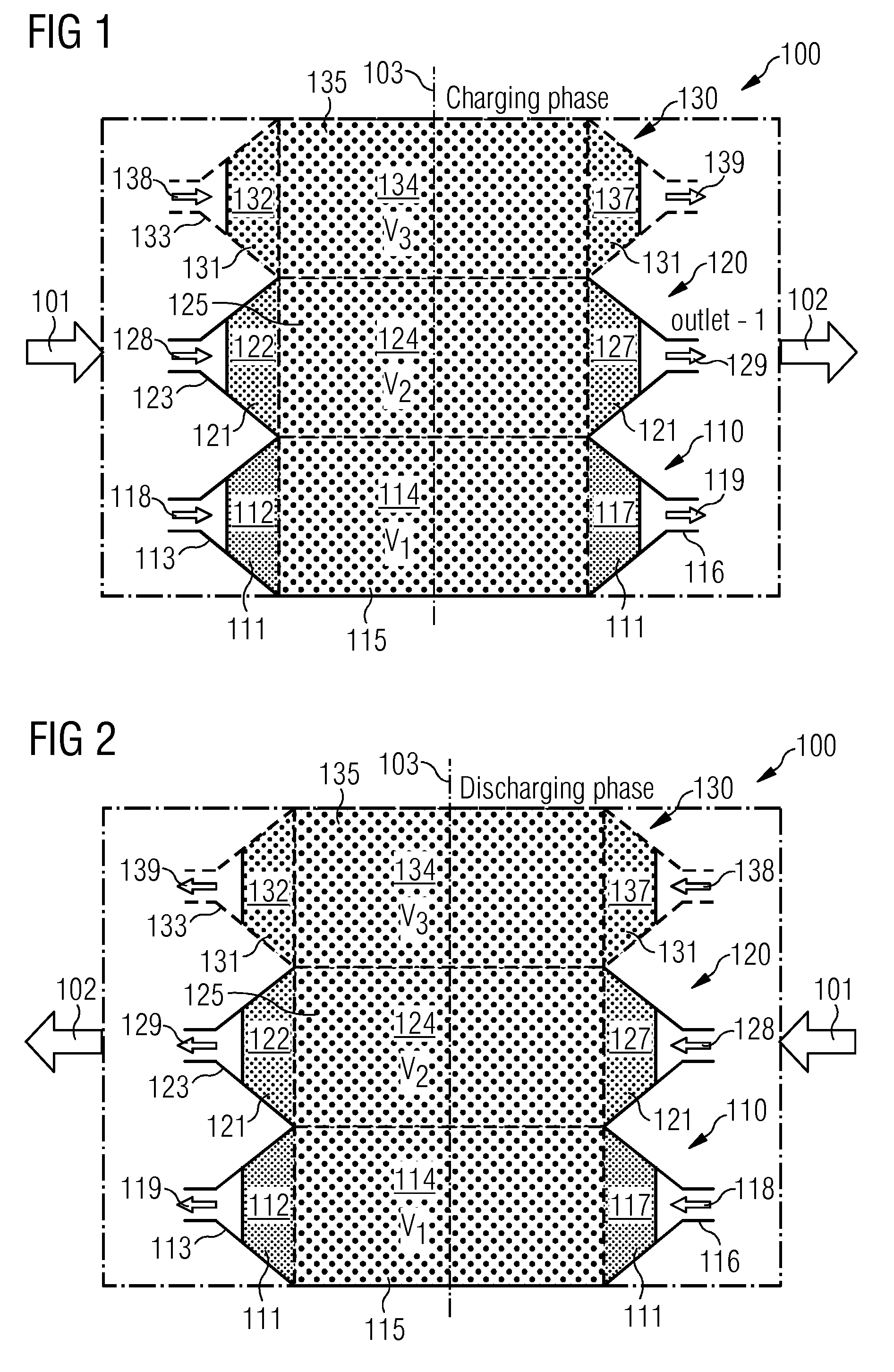

[0050]The illustration in the drawings is in schematic form. It is noted that in different figures, similar or identical elements are provided with the same reference signs.

[0051]FIG. 1 and FIG. 2 show a schematic view of a storage system 100 according to an exemplary embodiment of the present invention. The system 100 comprises a first housing section 110 with a first storage volume V1, wherein the first housing comprises a first opening 113 for connecting the first storage volume V1 to an environment. A first type 111 of first heat storing elements is arranged within the first housing section 110. The system further comprises a second housing section 120 with a second storage volume V2, wherein the second housing section 120 comprises a second opening 123 for connecting the second storage volume V2 to the environment, wherein the first storage volume V1 and the second storage volume V2 are interconnected for forming a common storage volume. A second type 121 of second heat storing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com