Reaction chamber with removable liner

a technology of reaction chamber and liner, which is applied in the direction of chemical vapor deposition coating, coating, metal material coating process, etc., can solve the problems of substrate coating failure, unusable use, reactant byproduct contamination of reaction chamber such as gas deposition chamber, etc., and achieve the effect of reducing the volume of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

ALD System First Embodiment

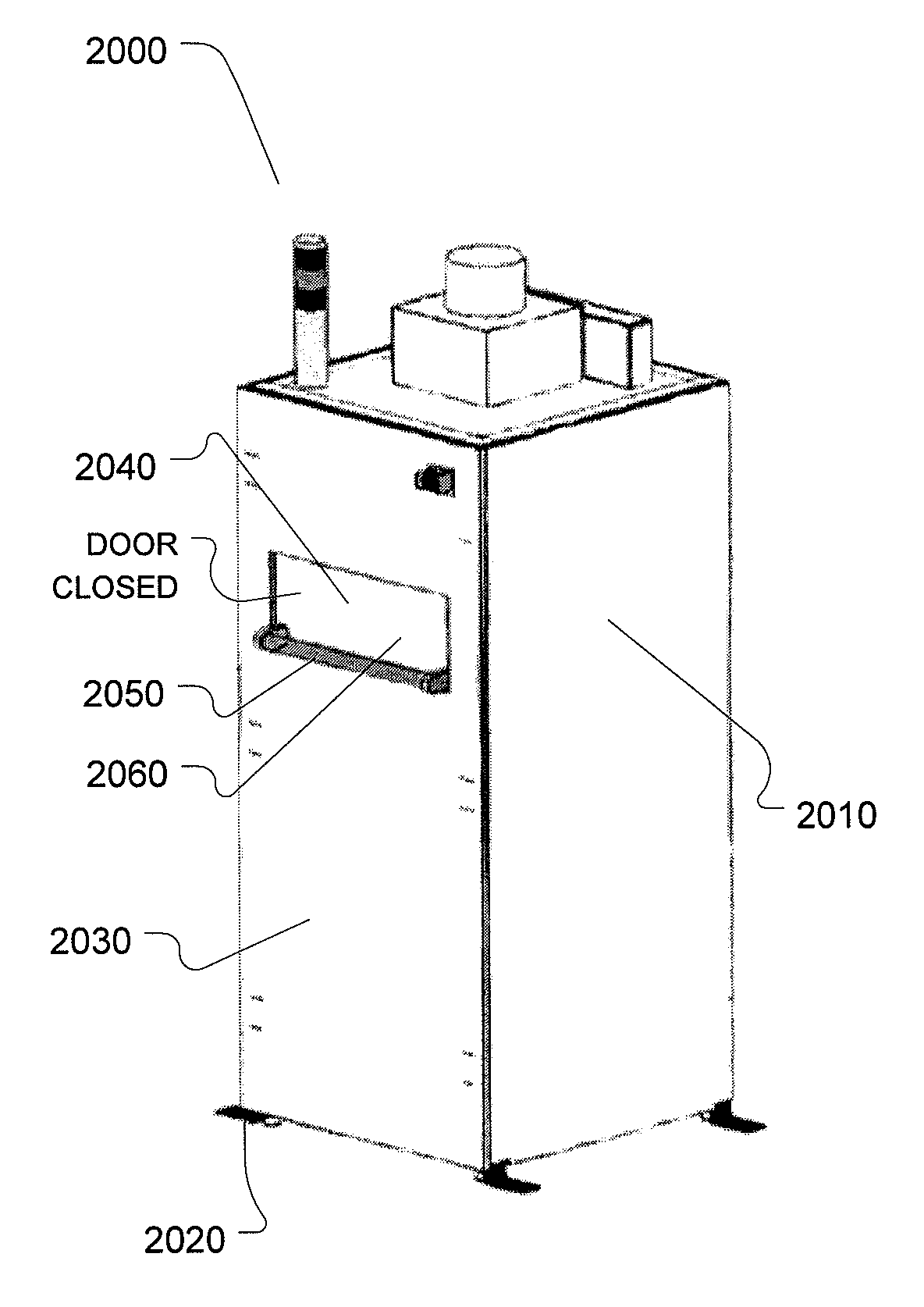

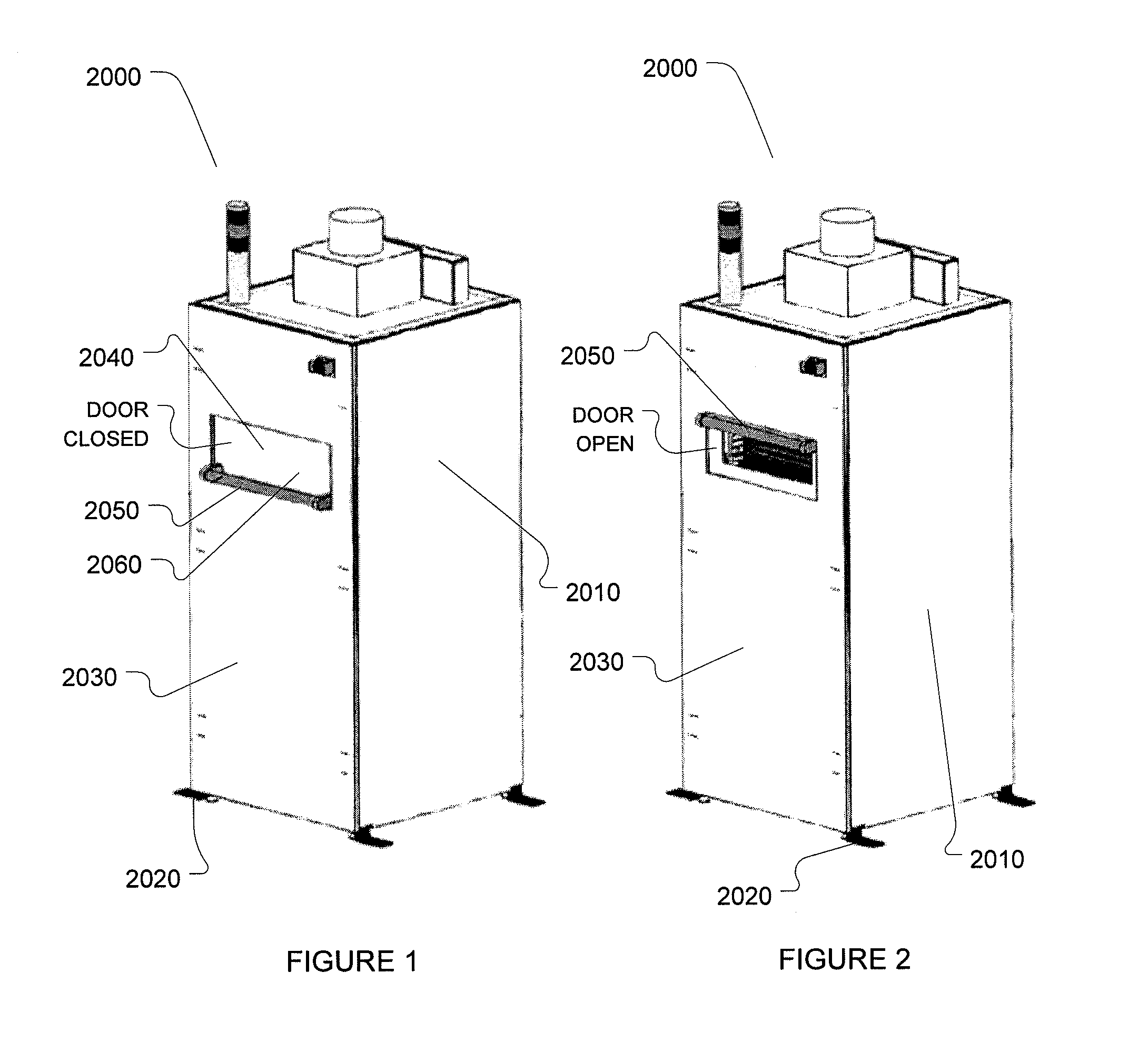

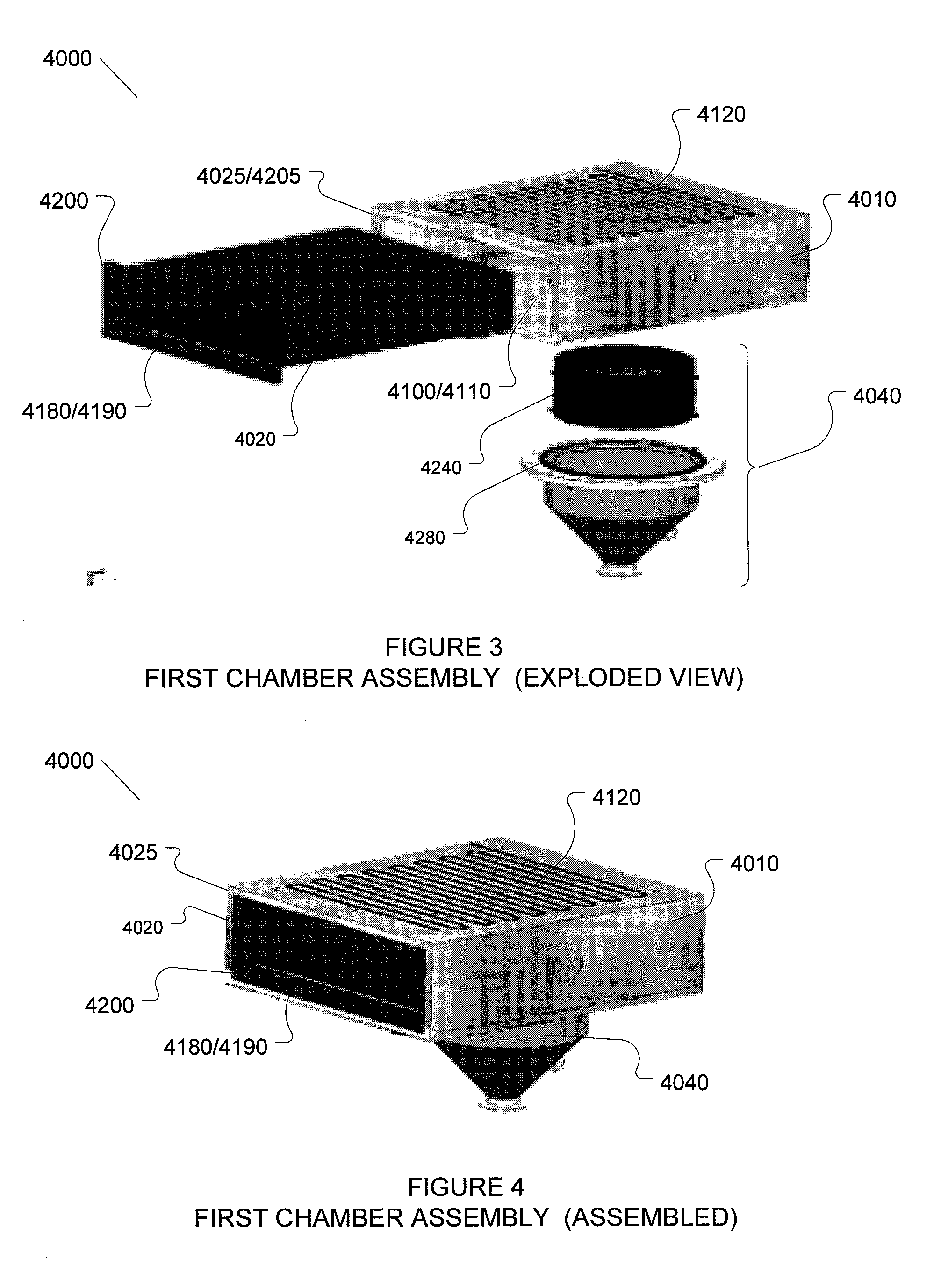

[0042]Referring to FIGS. 1 and 2, an exemplary first embodiment of an atomic layer deposition system (ALD) (2000) configured according to the present invention is constructed with a floor standing system cabinet (2010) supported on four feet (2020) having a front face (2030) that includes an access door assembly (2040). The access door assembly (2040) includes a door handle (2050) mounted on an outer door panel (2060). Both the outer door panel (2060) and the door handle are thermally insulated to protect an operator when handling the door handle (2050). The access door assembly (2040) is shown in a closed or operating position in FIG. 1 and in an open or loading / unloading position in FIG. 2. The access door assembly (2040) provides access through the system cabinet (2010) to a gas deposition or reaction chamber (4000) described below. The gas deposition chamber (4000) is housed inside the system cabinet (2010) behind the access door assembly (2040). In th...

second embodiment

ALD System Second Embodiment

[0082]A second exemplary embodiment of the present invention comprises a dual chamber gas deposition system (1000) shown in isometric view with the external skins removed in FIG. 11. The system (1000) includes a front face (1180) which is used for loading substrates into each of two gas deposition chambers (1120) and (1150). In a preferred embodiment, the front face (1180) interfaces with a clean room wall and the substrates are loaded and unloaded from inside the clean room through the clean room wall. For that reason, the removable liners installed into and removable from each of the gas deposition chambers of the second exemplary embodiment are installed and removed through a back face, opposed to the front face (1180).

[0083]A right side face (1130) includes a single user interface device (1200) which can be used to enter commands for operating both of the gas deposition chamber assemblies (1120) and (1150). In alternate embodiments, each gas depositio...

third embodiment

ALD System Third Embodiment

[0113]Referring now to FIGS. 14 and 18-19, a third embodiment of a chamber assembly (8100) according to the present invention is configured substantially like the reaction chamber (3000) described above except that the X-axis dimension of the chamber assembly (8100) is more than doubled and a removable liner (8110) is configured with six substrate trays (8120) instead on one substrate support surface. The substrate trays (8120) are supported in two stacks of three trays each with side by side substrate trays being substantially coplanar. Substrate trays (8120) are supported at each end thereof by a plurality of tray supports (8130) fixedly attached to the removable liner (8110). Each substrate tray (8120) supports a single substrate (7000) in a substantially horizontal orientation with a surface to be coated facing up.

[0114]The removable liner (8110) houses a reaction chamber (8140) suitable for batch coating six rectangular substrates (7000) supported on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dimension | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| operating temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com