Centrifugal pump

a centrifugal pump and centrifugal pump technology, applied in the direction of piston pumps, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of low change in cooling capacity, low circulation amount change of cooling water, and inability to generate easy change in cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

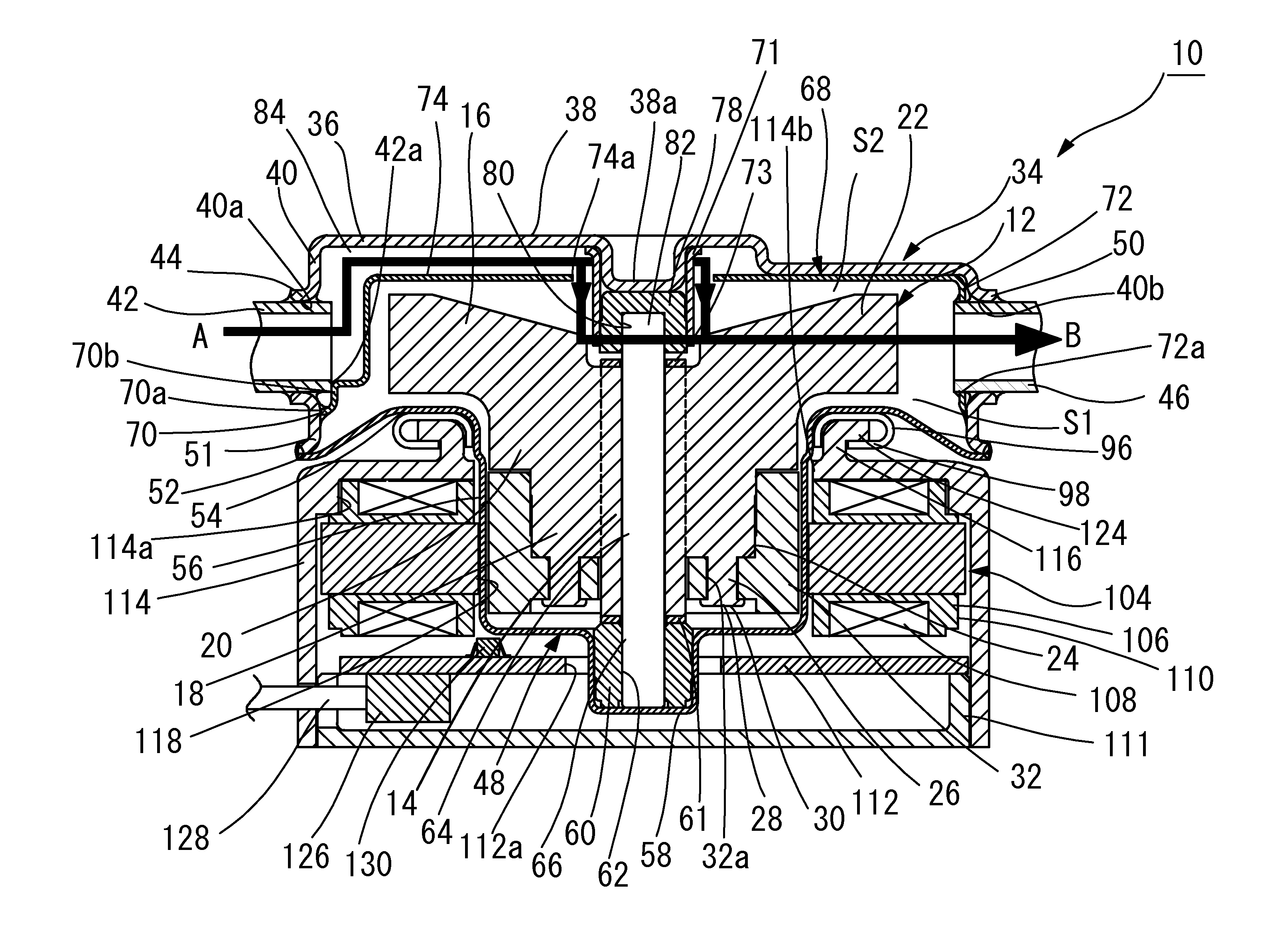

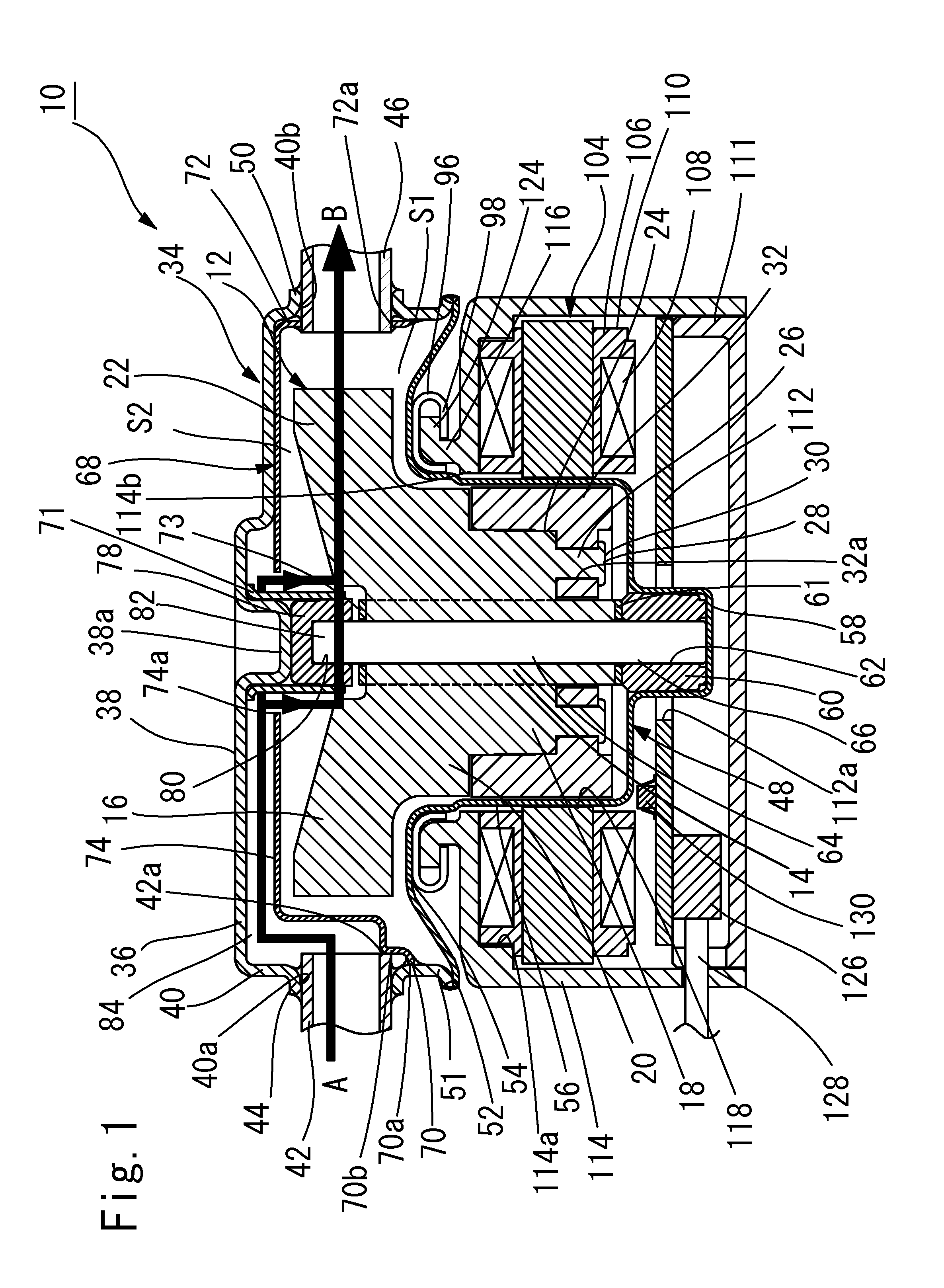

[0142]FIG. 1 is a longitudinal sectional view of an embodiment of the centrifugal pump.

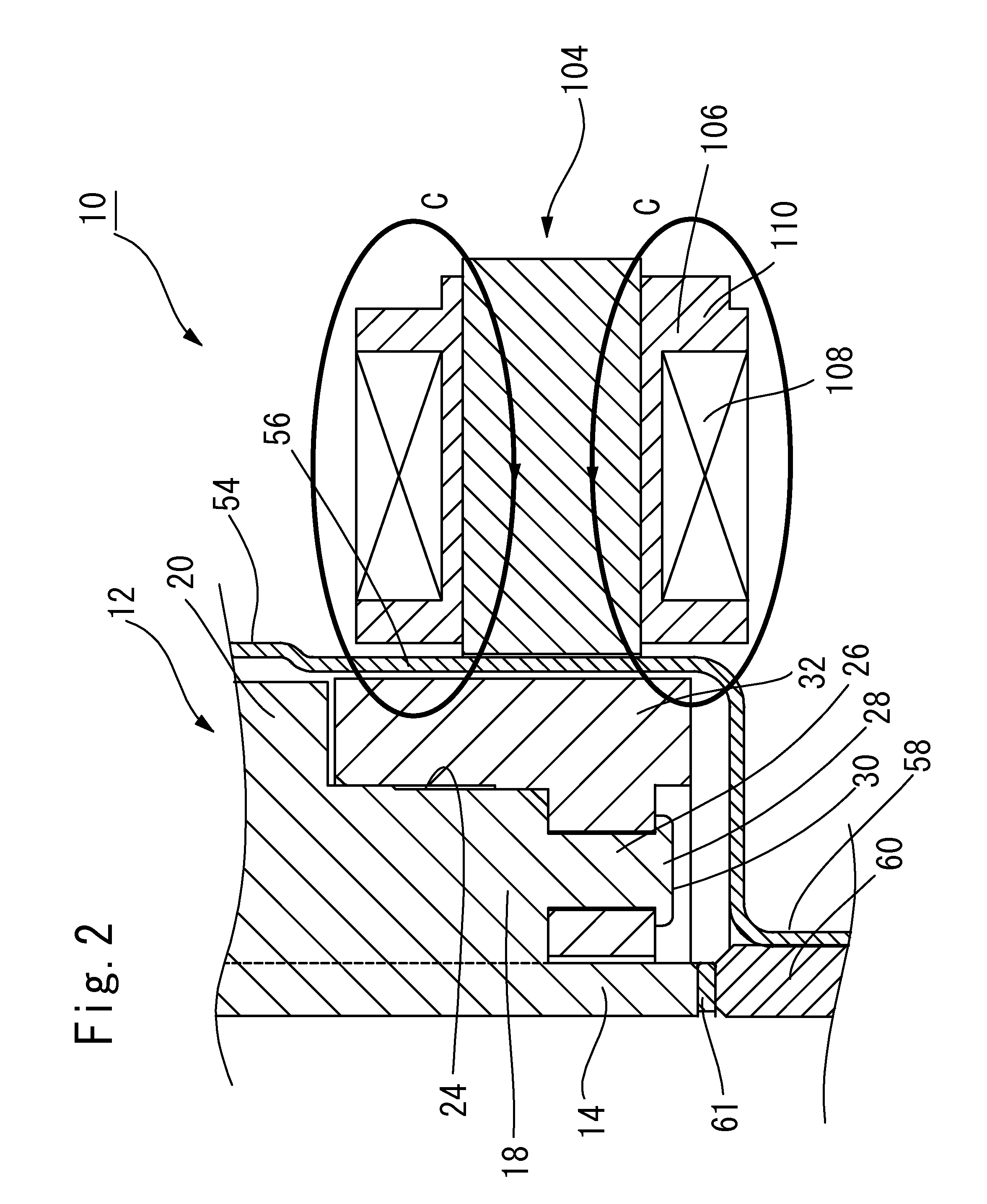

[0143]FIG. 2 is a partial enlarged sectional view of the centrifugal pump of FIG. 1.

[0144]FIG. 3 is a schematic cross-sectional view, in which disposing of the internal space S1, the fluid introducing passage 84, and the rotating accommodating space S2 of the centrifugal pump of FIG. 1.

[0145]In addition, in the specification, the wordings, such as “upper side”, “upper portion”, “upper”, “lower side”, “lower portion”, and “lower” which show vertical direction, indicate the vertical direction in each drawing.

[0146]Moreover, they indicate a relative position of each member and they do not indicate absolute position.

[0147]In FIG. 1-FIG. 2, reference numeral 10 shows exemplary centrifugal pump as a whole.

[0148]For convenience' sake of the clarification in FIG. 3, a main body casing 34, an upper main body casing 36, a lower main body casing 48, a blade casing 68, a suction side coupling member 42, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com