Produced water steam generation process using produced water boiler with gas turbine

a technology of produced water and gas turbine, which is applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of large amount of downtime in cleaning the boiler tube, ineffective heat transfer of the boiler, and large amount of downtime of the boiler tube, so as to avoid duplication of heat transfer surface area and add value. , the effect of simplifying the lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

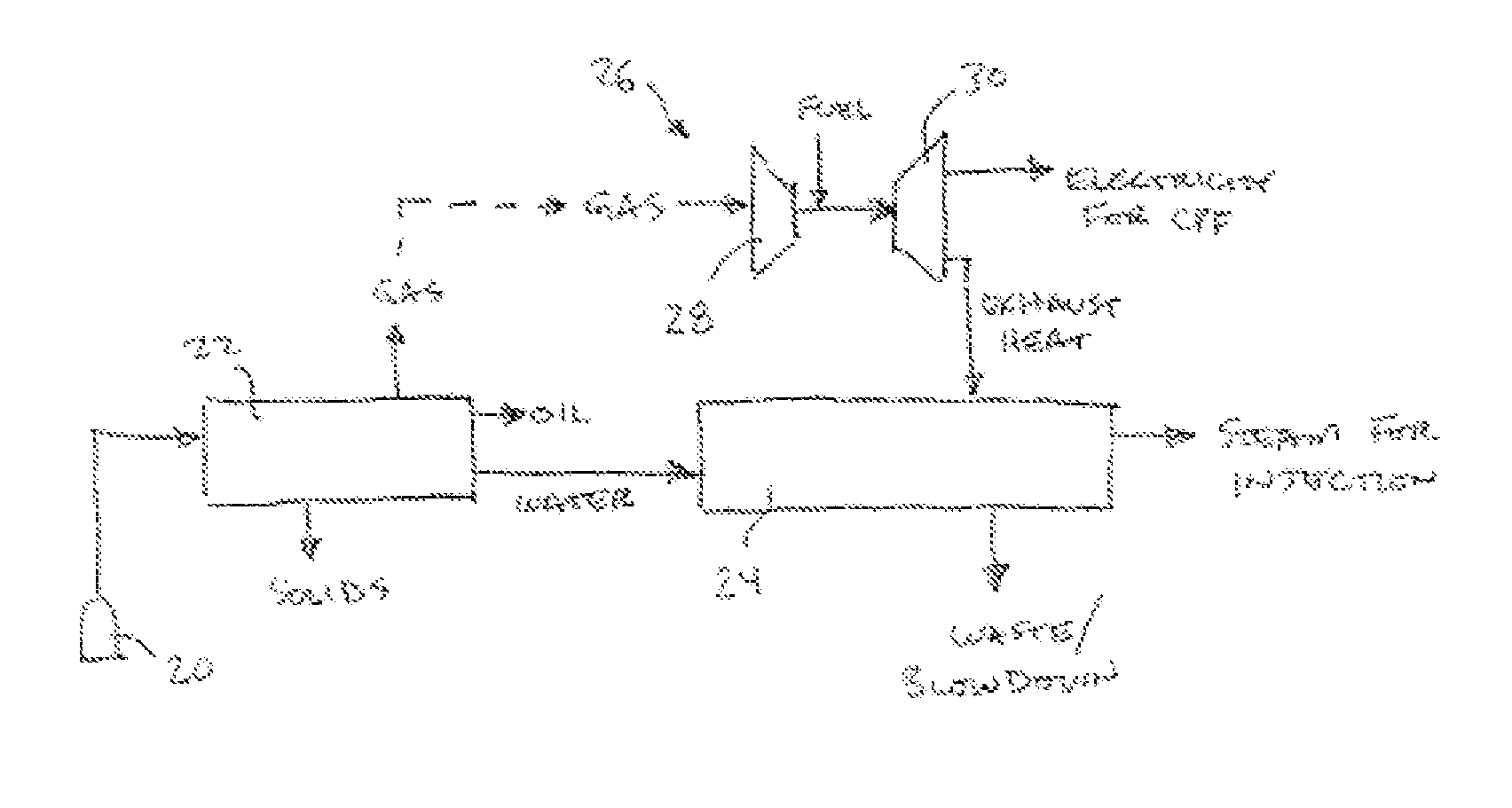

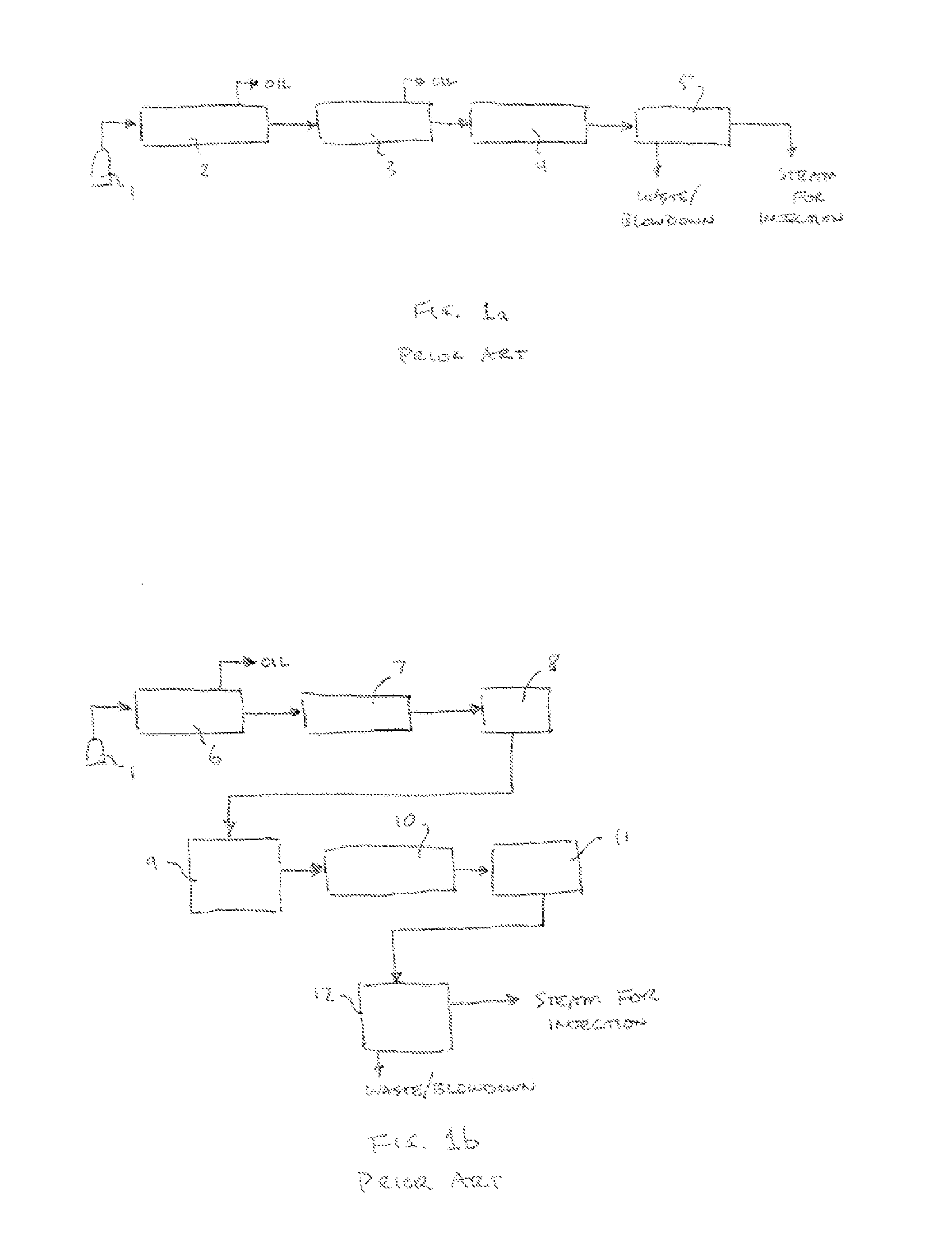

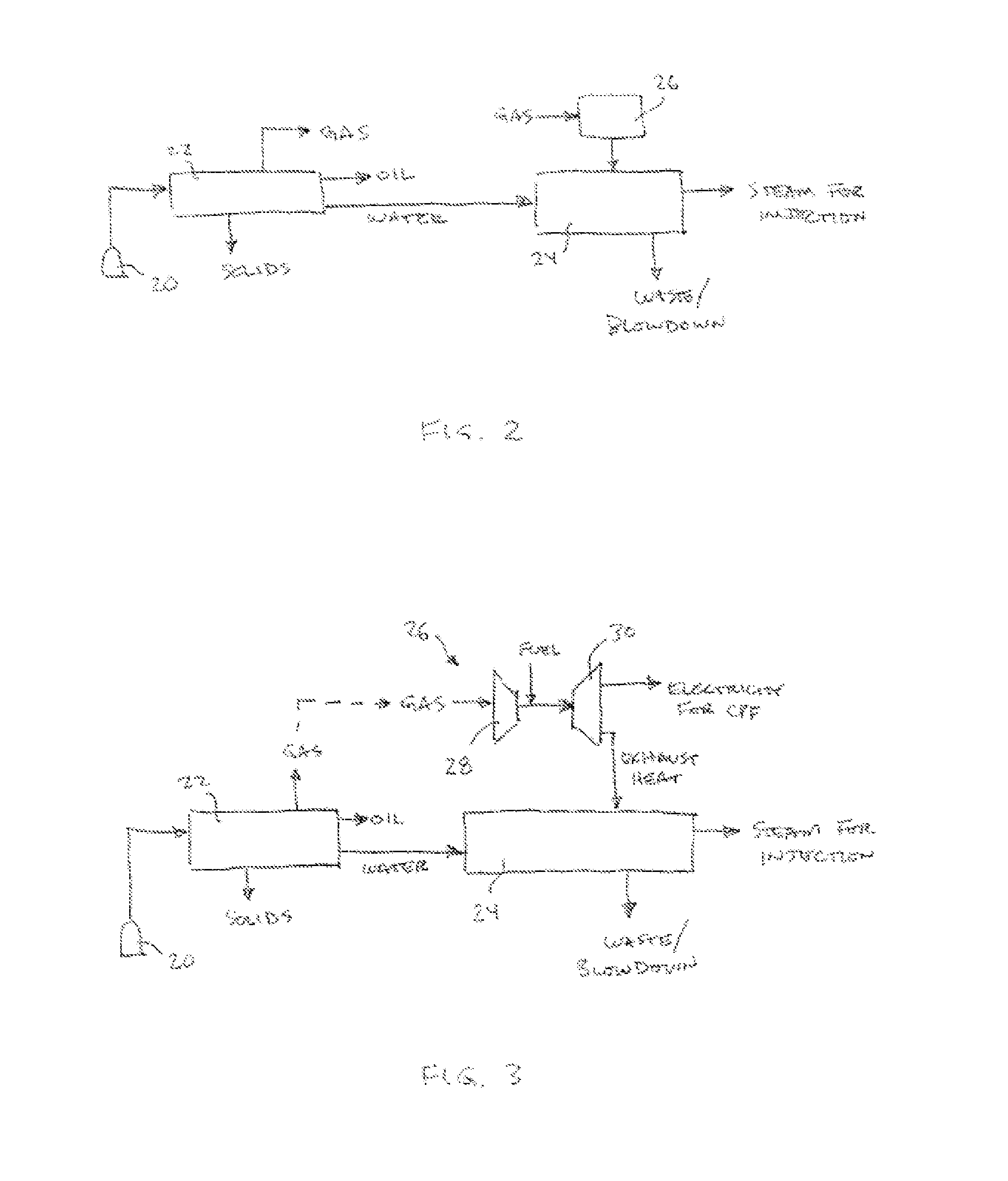

[0022]As mentioned above, conventional produced water steam generation systems involve a number of subsystems to separate and purify the produced water to a state that is acceptable as feedwater for the steam generation equipment. As is shown in FIG. 1A, the subsystems of a conventional prior art system for processing water produced from a wellhead 1 include a gas / oil / free water / solids separation stage 2, a produced water removal stage 3, a produced water treatment impurity removal stage 4 and steam generation 5. The oil / produced water separation stage 2 is designed to remove most of the oil from the water, the oil then being stored or pipelined elsewhere for processing, while the produced water—still somewhat contaminated with minor amounts of oil—must undergo additional processing in the oil removal stage 3 (in which further removed oil is recovered and processed). The produced water treatment impurity removal stage 4, as discussed above, removes various impurities from the de-oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com