High-strength rigging and preparation method thereof

a rigging and high-strength technology, applied in the field of polymer material application, can solve the problems of high cost and relatively low strength utilization ratio, and achieve the effects of reducing the probability of burrs, good structural integrity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0040]As shown in FIG. 3, the embodiment provides a preparation method of a high-strength rigging, at least comprising the following step:

step S101: preparing a body of the high-strength rigging from an ultra-high molecular weight polyethylene thin film or strip.

[0041]In addition to the body, the high-strength rigging provided in each embodiment of the invention may comprises a sheath and other structures, and the body is a main part for bearing force.

[0042]Preparing the body of the high-strength rigging from the ultra-high molecular weight polyethylene thin film or strip specifically comprises: converging the ultra-high molecular weight polyethylene thin film or strip to prepare a single yarn and using the prepared single yarns to replace traditional ultra-high molecular weight polyethylene fibers to prepare the rigging, for example, various wires, riggings, strips and the like.

[0043]In addition, the ultra-high molecular weight polyethylene thin film or strip can also be used for d...

embodiment 2

[0048]The embodiment provides a preparation method of a high-strength rigging, comprising the step of converging or converging and twisting the ultra-high molecular weight polyethylene thin film or strip into a single yarn to obtain a body.

[0049]The body of the high-strength rigging in the embodiment is the single yam formed by converging the ultra-high molecular weight polyethylene thin film or strip, or the single yam formed by converging and twisting the ultra-high molecular weight polyethylene thin film or strip, thereby having a linear structure.

[0050]The ultra-high molecular weight polyethylene thin film or strip is converged along the straightening direction of a molecular chain thereof.

[0051]Preparing the body by converging the ultra-high molecular weight polyethylene thin film or strip specifically comprises: placing the ultra-high molecular weight polyethylene thin film or strip on a reeling and unreeling device for converging to obtain the single yam, as the stress direct...

embodiment 3

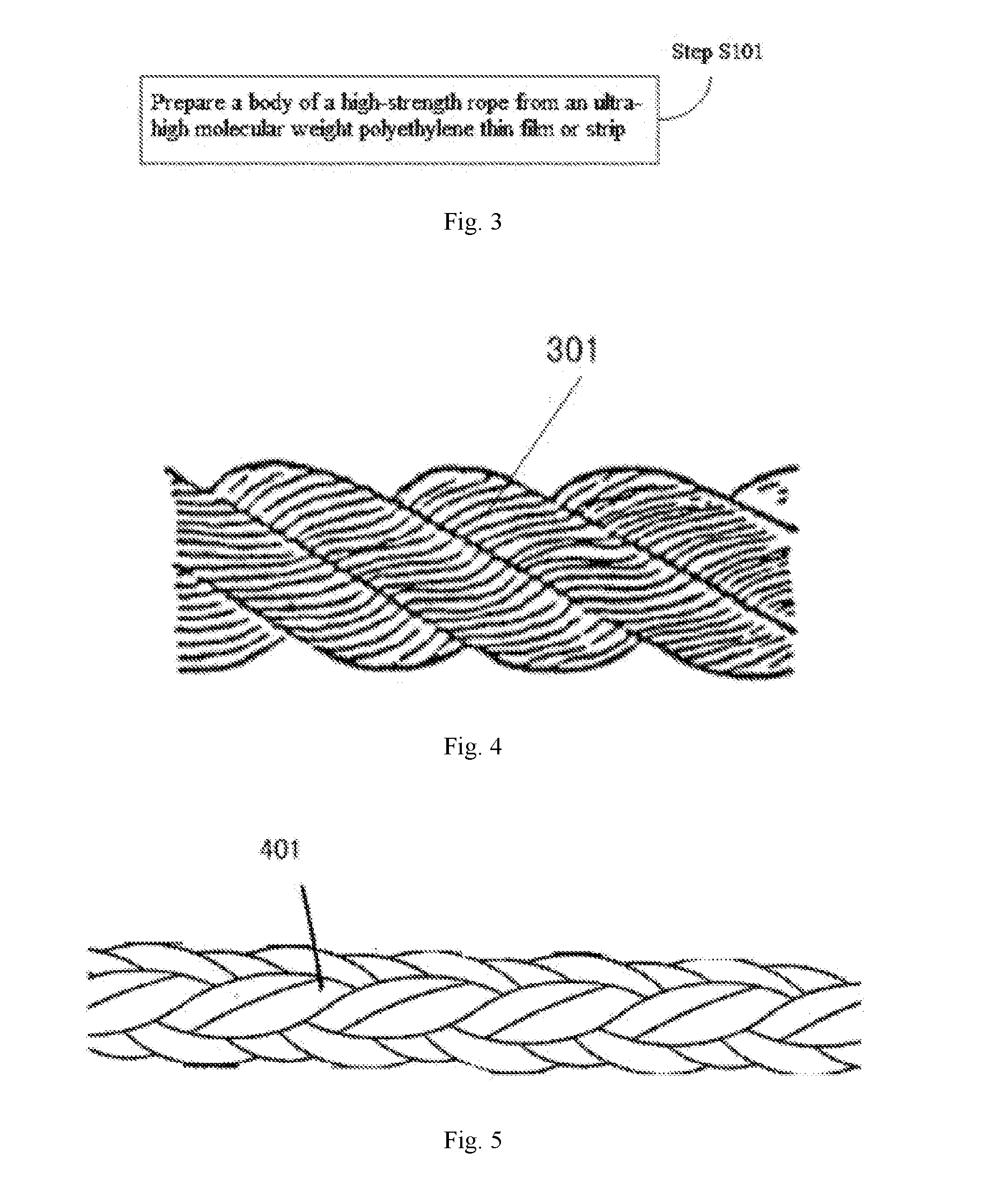

[0054]The embodiment provides a preparation method of a high-strength rigging, comprising integrally arranging multiple single yarns to form the body, wherein each single yarn is prepared by converging or converging and twisting the ultra-high molecular weight polyethylene thin film or strip.

[0055]The high-strength rigging in the embodiment at least comprises the body prepared by the ultra-high molecular weight polyethylene thin film or strip, the body comprises multiple single yarns, each single yarn is prepared by converging the ultra-high molecular weight polyethylene thin film or strip, or each single yarn is prepared by converging and twisting the ultra-high molecular weight polyethylene thin film or strip, and the high-strength rigging in the embodiment has a rigging-like structure.

[0056]Each single yarn is converted along the straightening direction of a molecular chain of the ultra-high molecular weight polyethylene thin film or strip.

[0057]Using the multiple single yarns, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com