Ultraviolet Reflective Rough Adhesive Contact

a technology of reflective contact and adhesive contact, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical apparatus, etc., can solve the problems of resistive losses at the contact junction, low overall efficiency of these devices, and difficult to form good ohmic contact to the semiconductor layer, etc., to achieve good contact adhesion, increase light extraction efficiency, and low electrical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

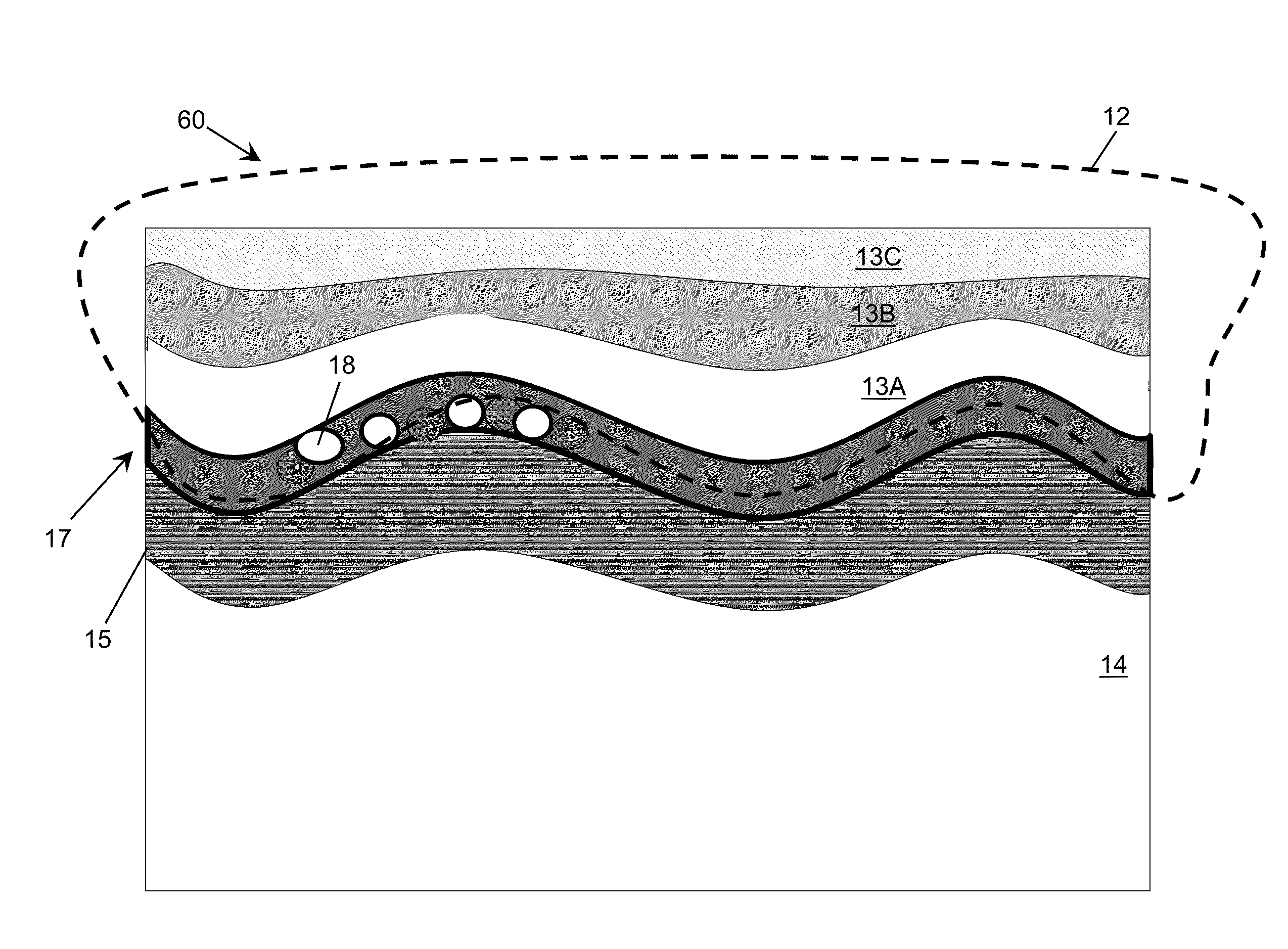

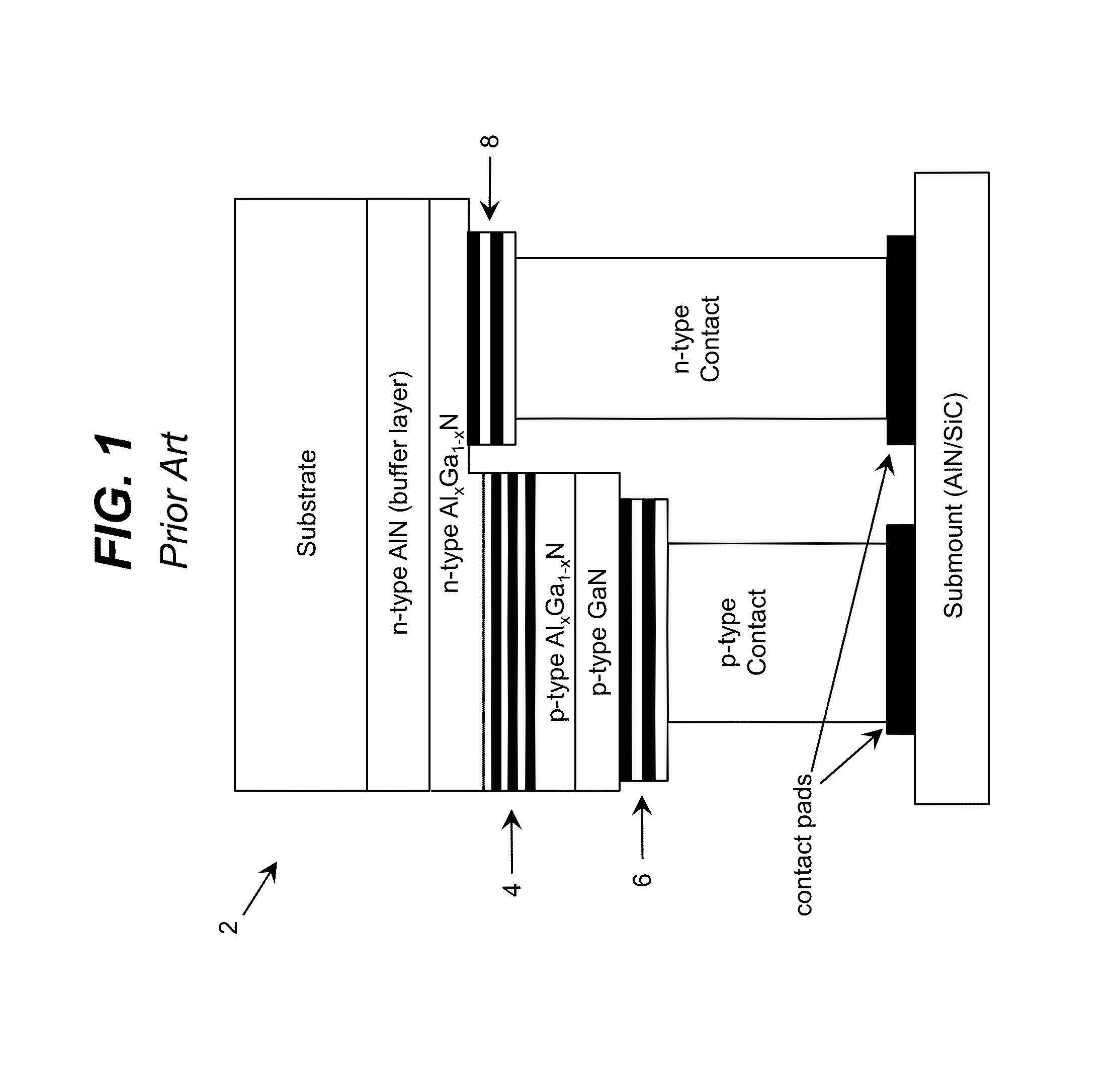

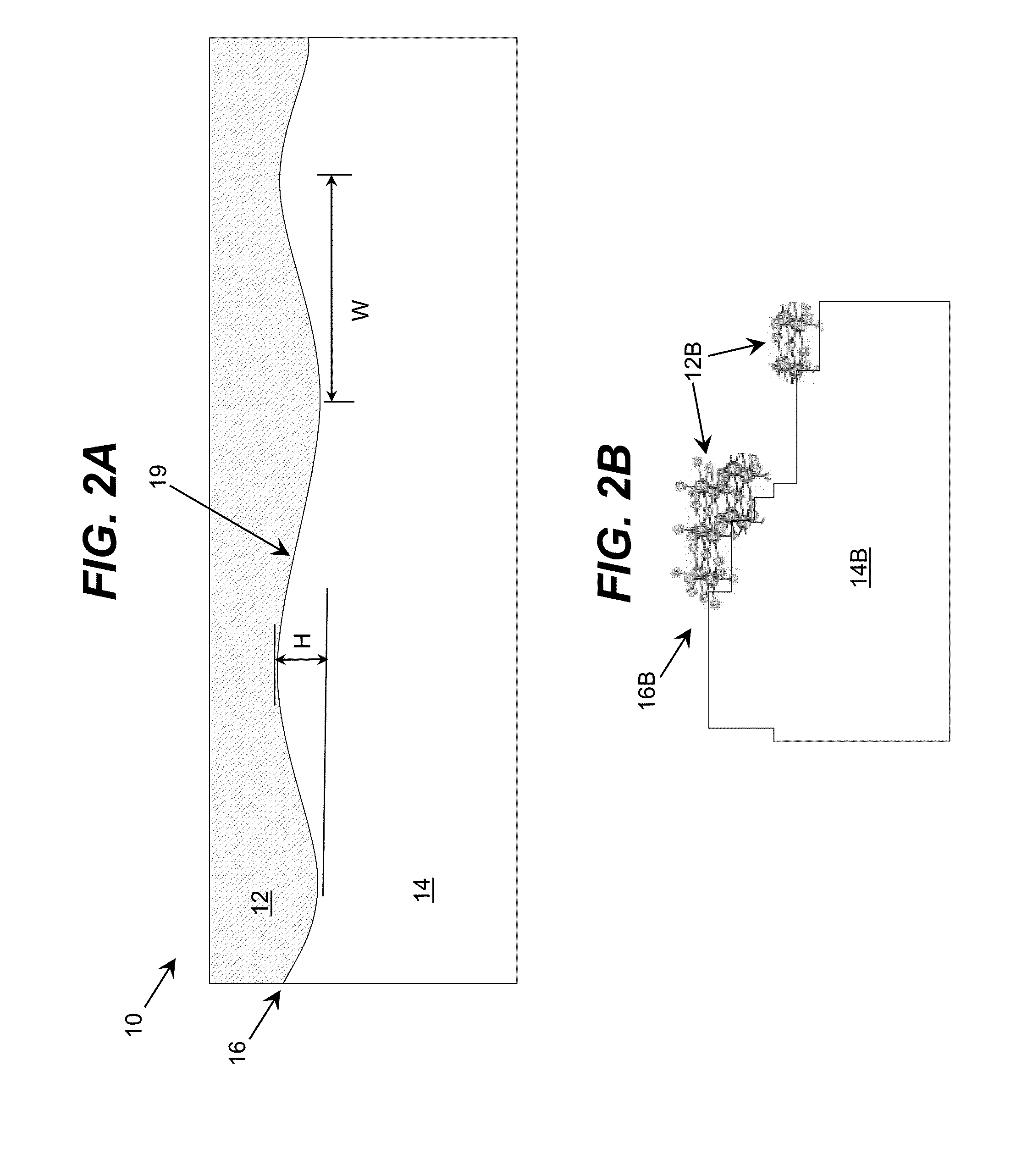

[0034]As indicated above, aspects of the invention provide a device including a first semiconductor layer and a contact to the first semiconductor layer. An interface between the first semiconductor layer and the contact includes a first roughness profile having a characteristic height and a characteristic width. The characteristic height can correspond to an average vertical distance between crests and adjacent valleys in the first roughness profile. The characteristic width can correspond to an average lateral distance between the crests and adjacent valleys in the first roughness profile. As used herein, unless otherwise noted, the term “set” means one or more (i.e., at least one) and the phrase “any solution” means any now known or later developed solution.

[0035]Furthermore, it is understood that a contact formed between two layers is considered “ohmic” or “conducting” when an overall resistance of the contact is no larger than the larger of the following two resistances: a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com