System for handling riser pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

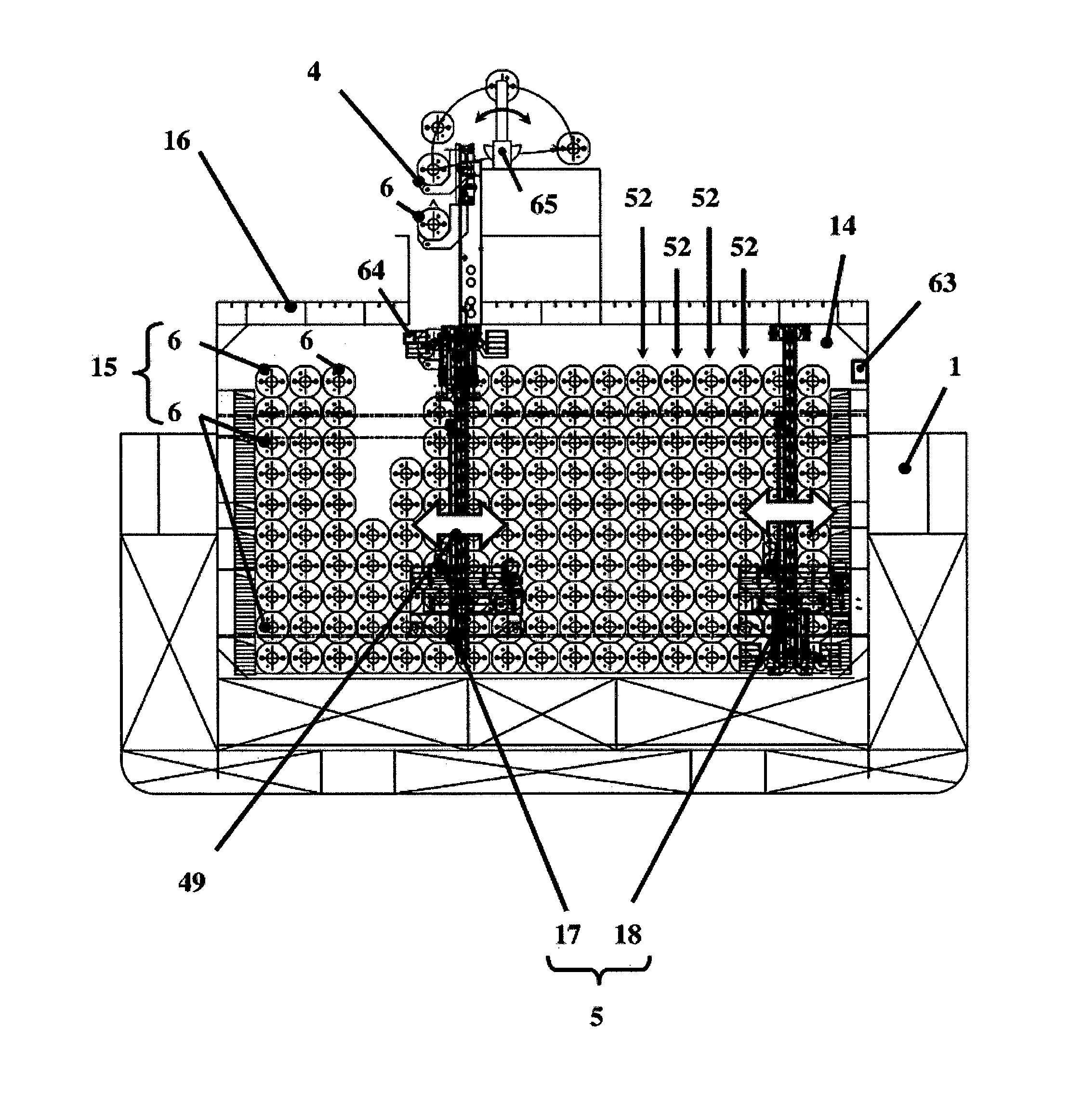

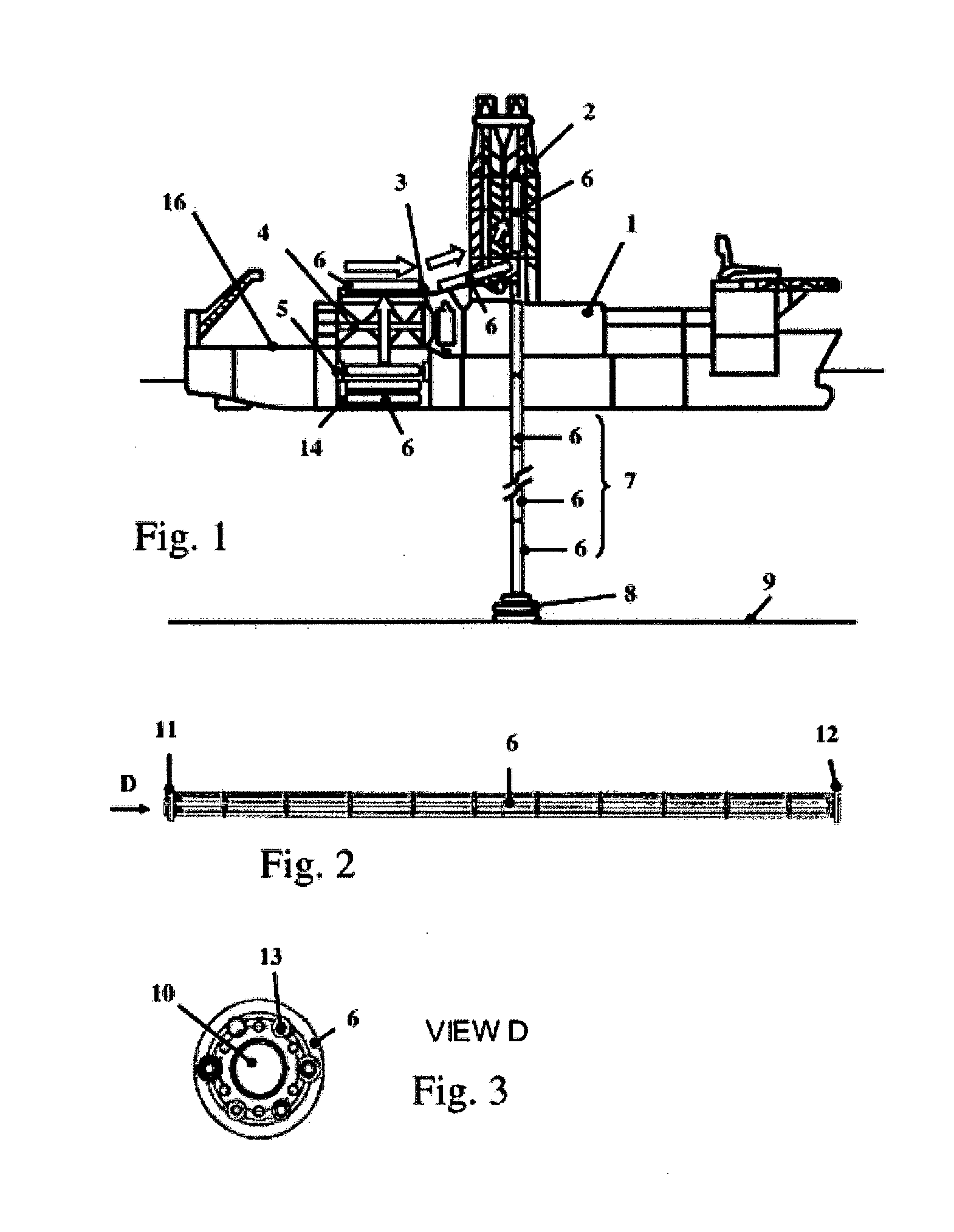

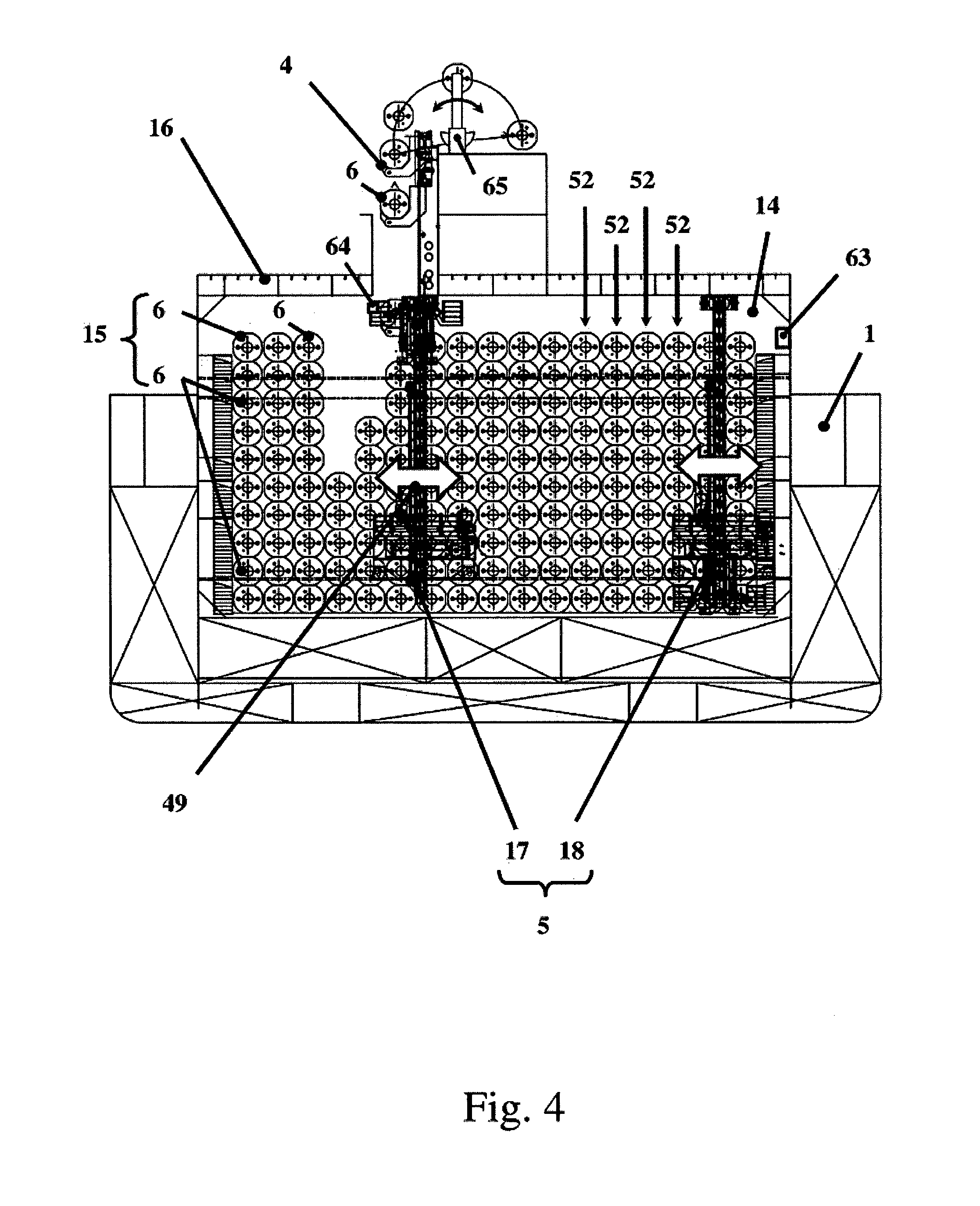

[0081]With reference to the figures (FIG. 1) the present invention finds application in the movement of tubular elements (6) from a storage zone (14) of a vessel (1) towards at least one laying or use zone (2) of the tubular elements. For example, without limitation for the purpose of the present invention, in the case of a drillship or in the case of a semisubmersible drilling rig, the tubular elements will be risers that are taken from a storage zone (14) that can be a hold or a deposition zone on the deck. The risers (6) are (FIG. 2, FIG. 3) normally tubular elements flanged in correspondence with a first end (11) and in correspondence with a second end (12) that are opposite ends with respect to the longitudinal development of the tubular element in the form of a riser. The riser (FIG. 3) includes a main hole (10) and a number of auxiliary lines (13) for the passage of the control fluids, as well as floating pushing elements inserted around the structure of the riser itself. Onc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com