Steam Micro Turbine Engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

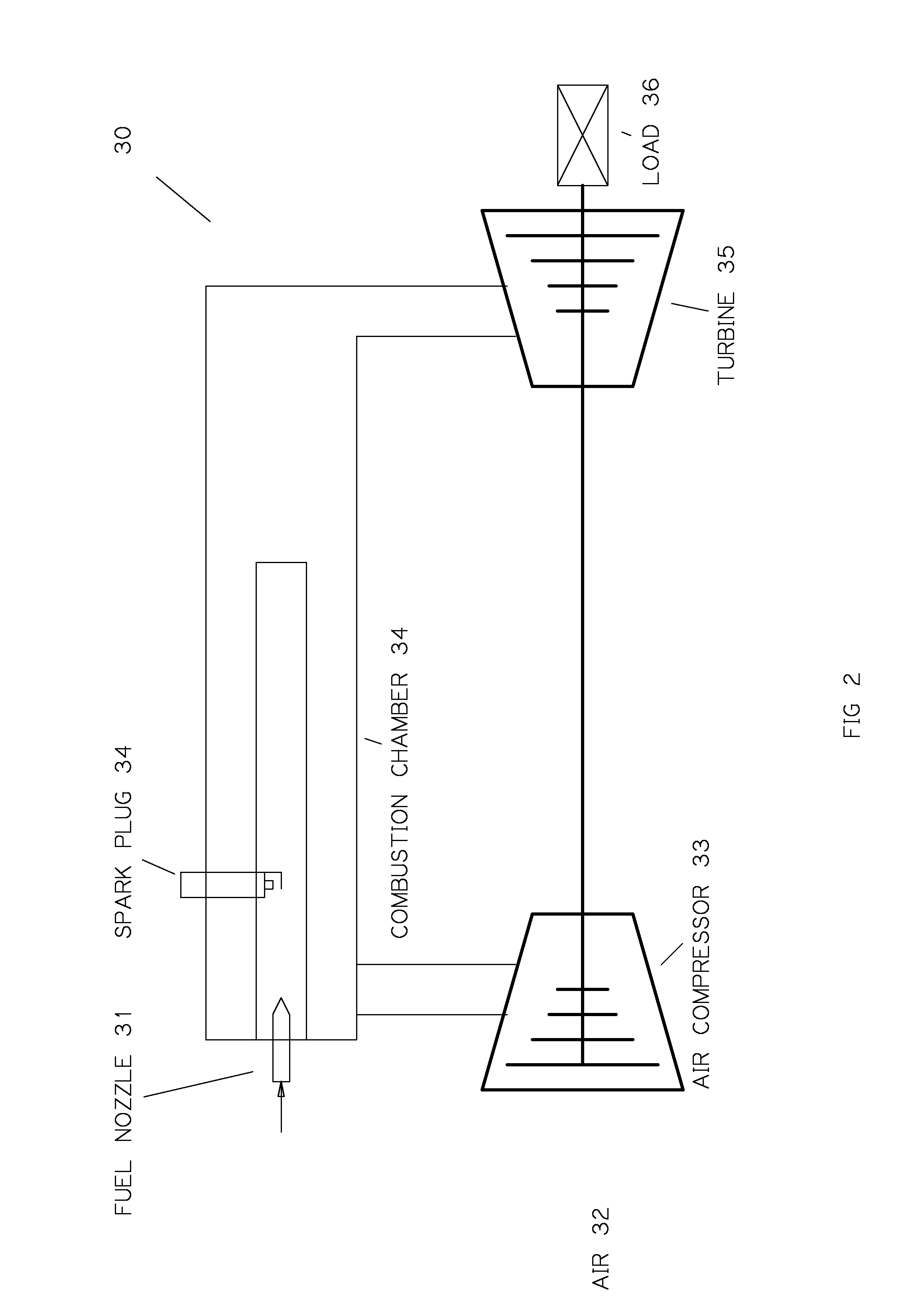

[0023]With reference to FIG. 2, a traditional micro turbine engine 30 comprises of air compressor 33, combustion chamber 34, turbine 35, spark plug 34 and fuel nozzle 31. A fresh air steam is compressed by the compressor 33 and enters into combustion chamber 34. It is mixed with the fuel injected by fuel nozzle 31. The spark plug 34 ignites the air-fuel mixture. The mixture is heated by energy released by the chemical reaction in the burn process and expanding with higher volume and velocity. This exhaust gas flows through turbine to extract energy for useful mechanical work.

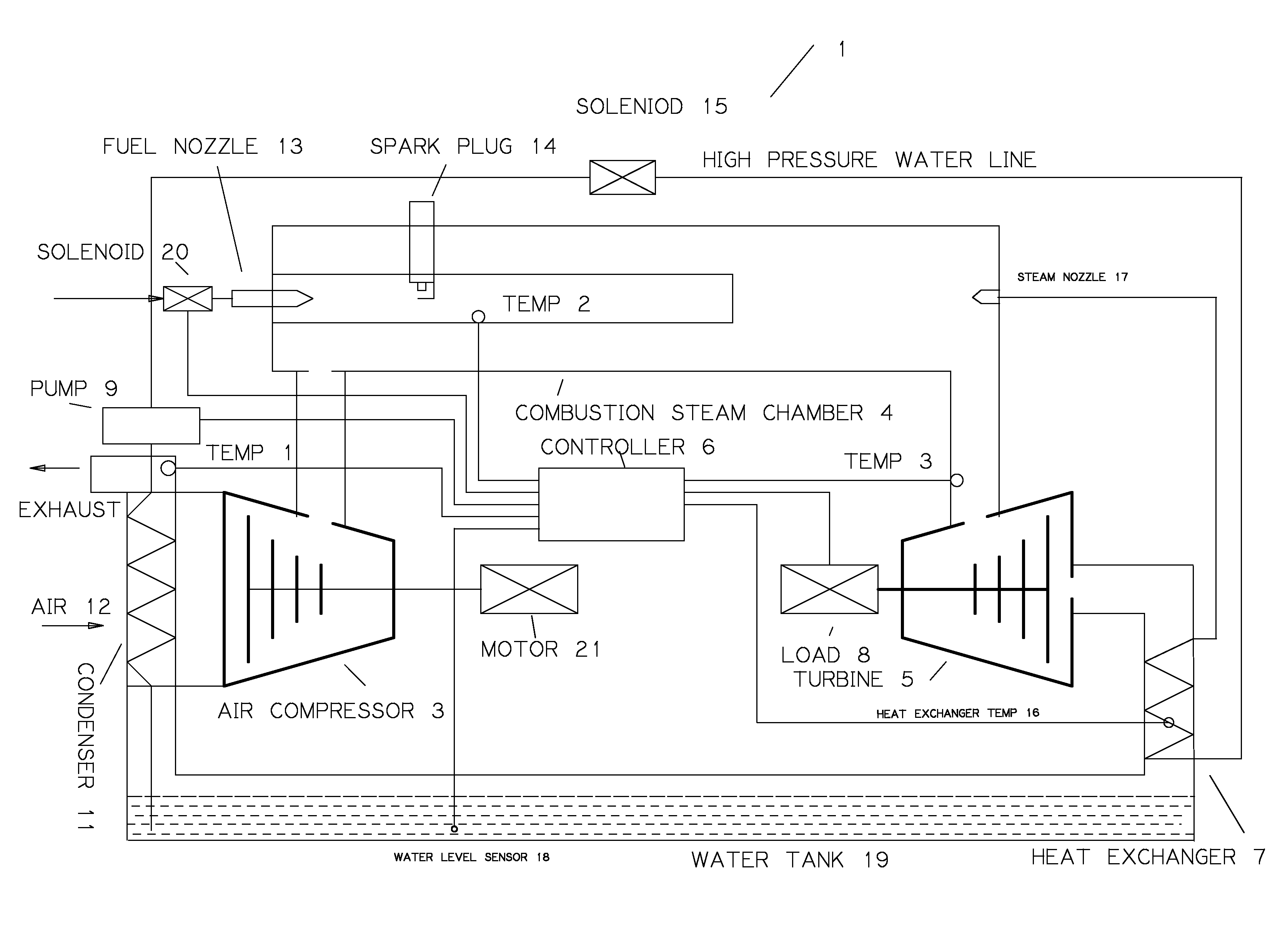

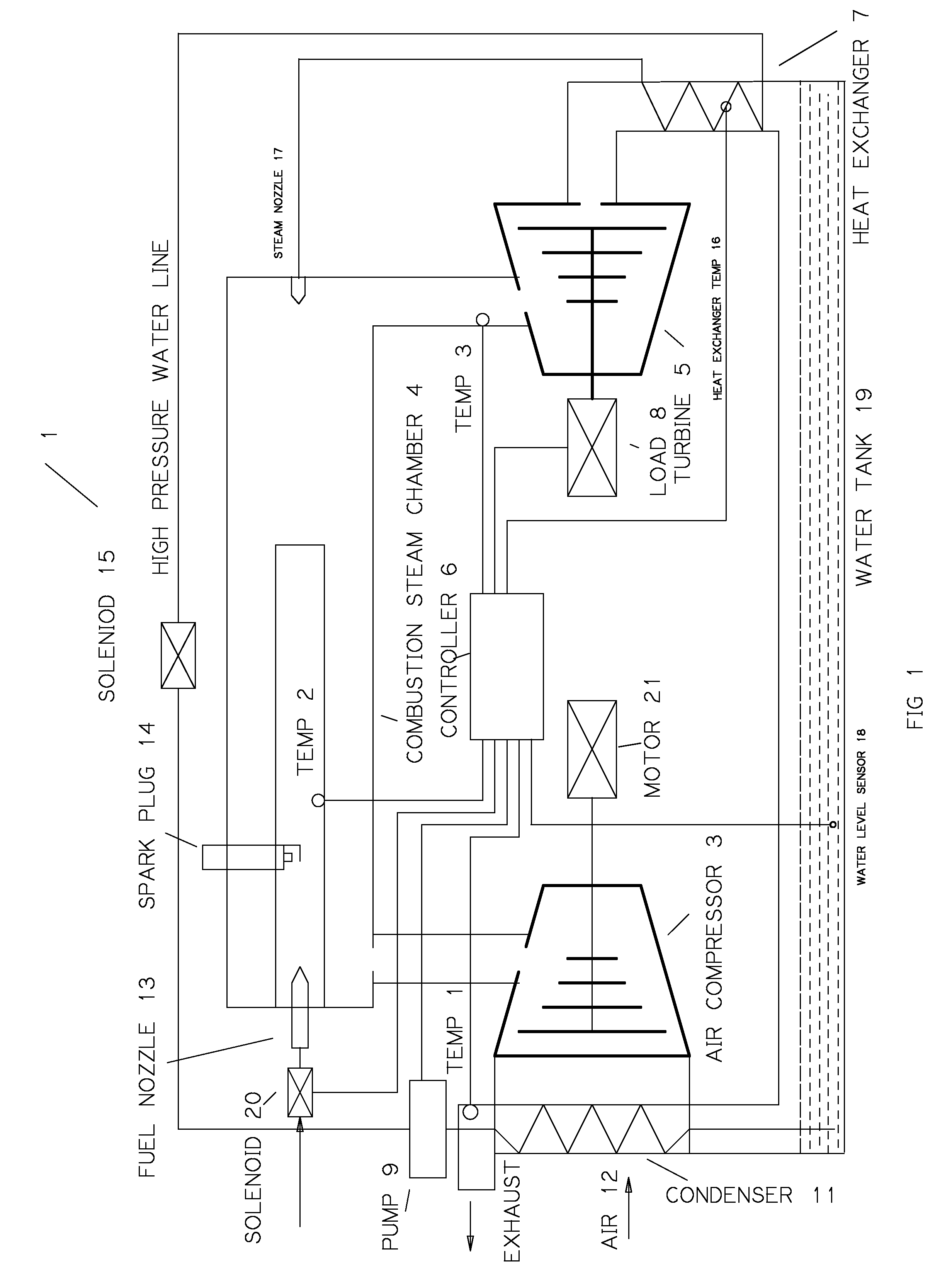

[0024]With reference to FIG. 1, a steam micro turbine engine 1 in accordance to an aspect of the present disclosure comprises of air compressor 3, combustion steam chamber 4, turbine 5, controller 6, water heat exchange 7, water pump 9, spark plug 14, water solenoid 15 and fuel nozzle 13.

[0025]A fresh air stream is heated by a condenser 11 and flows through into the compressor 3. The compressed heated air enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com