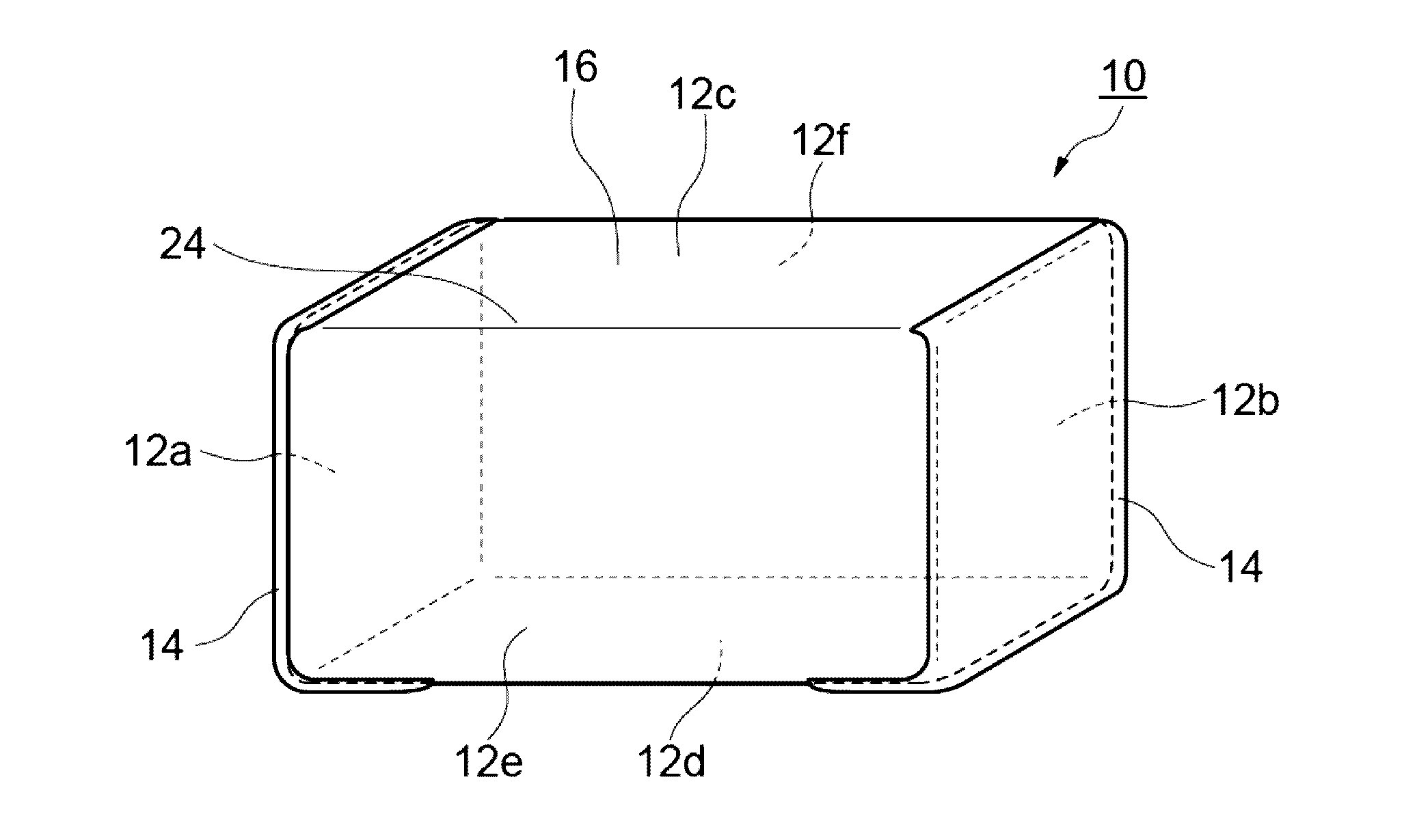

Multilayer ceramic capacitor

a multi-layer ceramic and capacitor technology, applied in the direction of fixed capacitors, stacked capacitors, fixed capacitor details, etc., can solve the problems of lower reliability and lower and achieve the effect of lowering the reliability of multi-layer ceramic capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

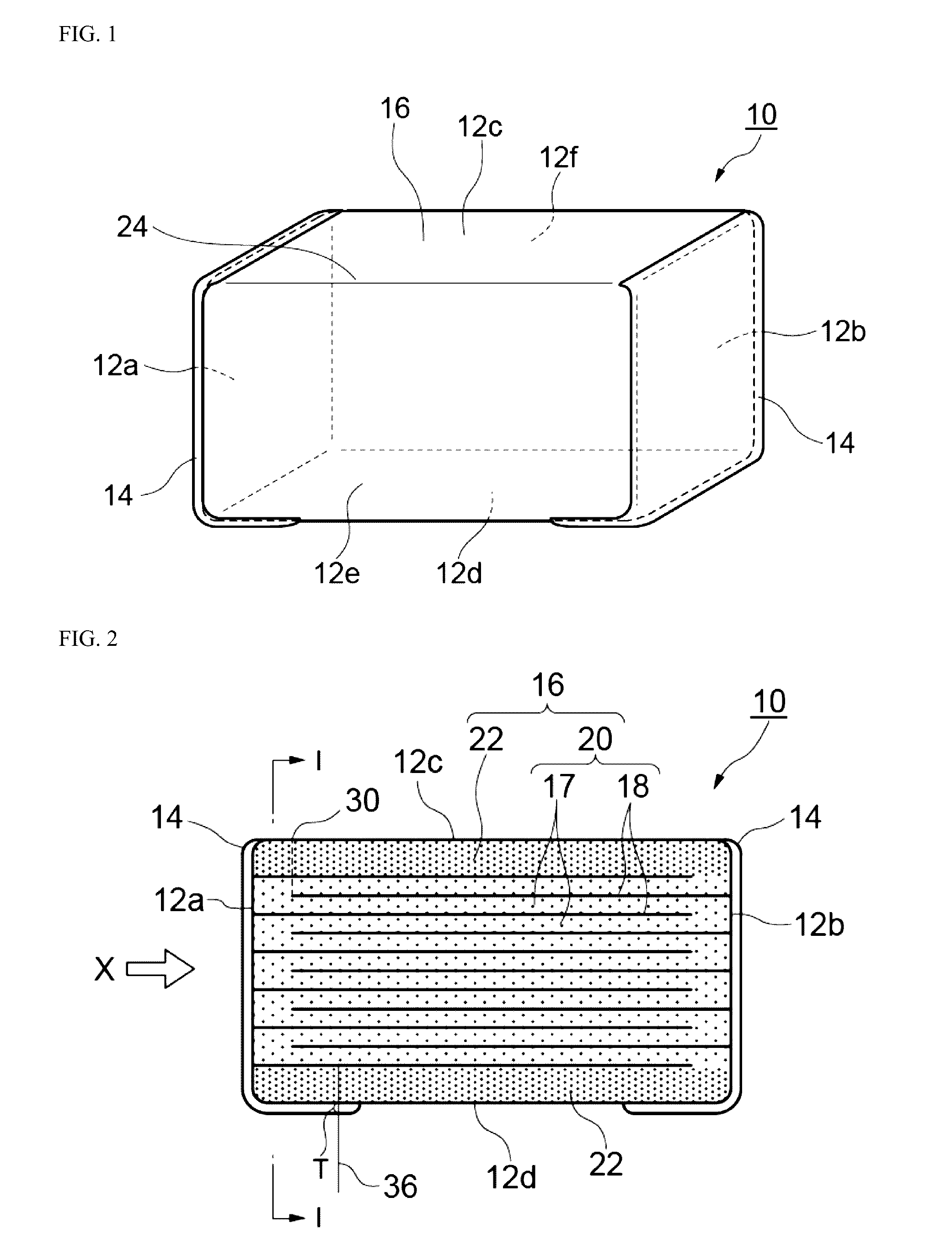

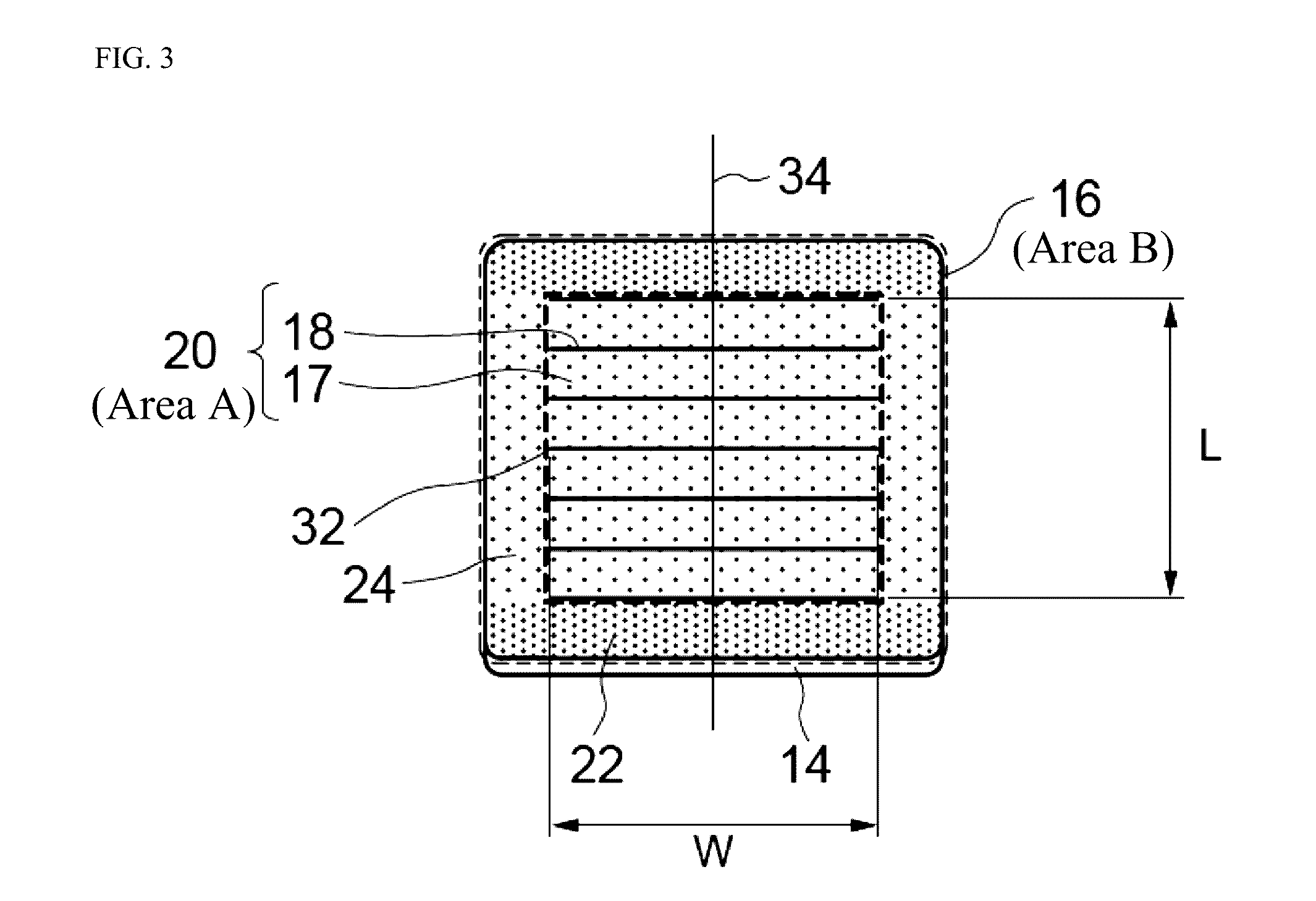

Method used

Image

Examples

examples

[0112]The present invention is explained in greater detail below using examples. It should be noted, however, that the present invention is not limited to these examples in any way.

[0113][Manufacturing of Multilayer Ceramic Capacitor]

[0114]To 100 mol of barium titanate of 0.1 μm in average grain size, Dy and Mg were each added by 1.0 mol, and V and Mn were each added by 0.5 mol, into which organic solvent whose primary constituent is alcohol, polyvinyl butyral resin, dispersant, and plasticizer were mixed and dispersed to produce a coating slurry. Then, this slurry was coated on a base material using a die-coater to produce a dielectric green sheet. The amount of slurry supplied to the die-coater was adjusted to control the thickness of sheet.

[0115]Next, the aforementioned dielectric green sheet was screen-printed with a conductive paste prepared by mixing and dispersing Ni powder of 200 nm in average grain size, organic solvent whose primary constituent is alcohol, ethyl cellulose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com