Rigid board plastic flooring and its production method

a technology of rigid board and plastic flooring, applied in the field of flooring products, can solve the problems of plasticizers that can cause serious effects, reduce the survival rate of animals, reduce the hepatorenal function, and reduce the erythrocyte count, so as to achieve the effect of great strength and more environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following further explains the invention by combining the figures:

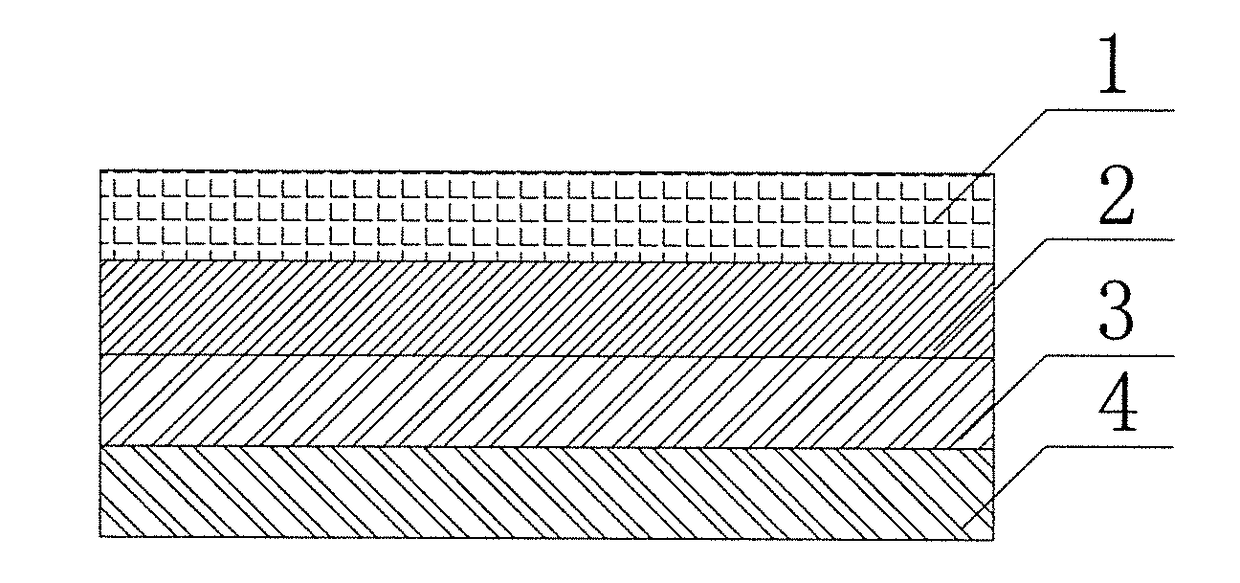

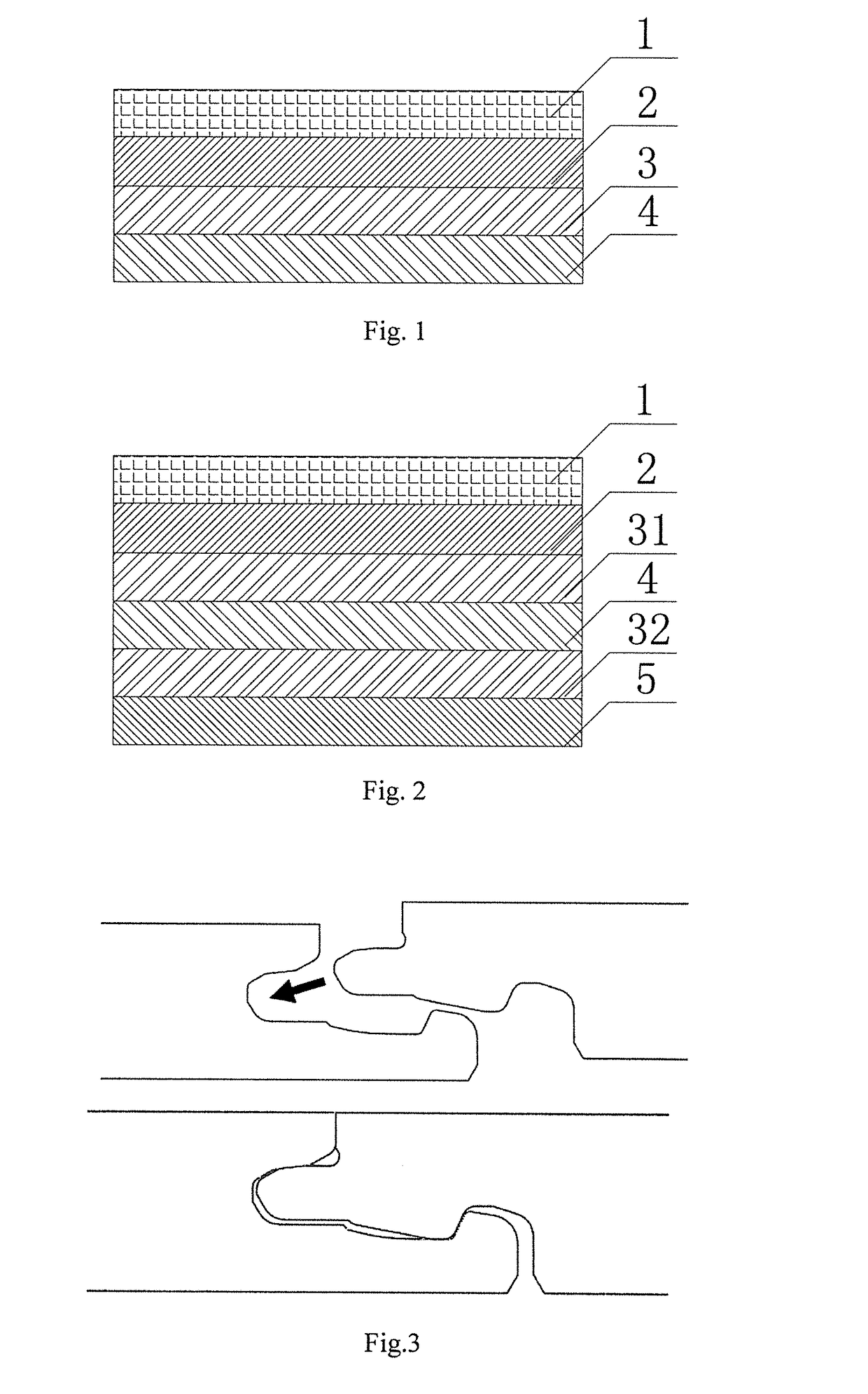

[0031]As shown in FIG. 1, the product comprises a wear layer 1, a decoration layer 2, a connecting layer 3 and a bottom layer 4, which are connected in sequence. The surface layer shall include a transparent wear layer of 0.1-1.0 mm thickness and can be prepared from transparent polymer materials such as PP, PE, PVC, PET, ABS, PC, POM, PMMA, PS, PEEK, PTFE, PVDF, etc. The second layer includes a decoration layer and this can be prepared from polymer materials such as PP, PE, PVC, PET, ABS, PC, POM, PMMA, PS, PEEK, PTFE, PVDF, etc. The third layer includes a connecting layer of 0.01-0.5 mm thickness and 5-300 g / m2 in terms of gram weight and can be prepared from the membrane or cloth which is not adhesive at room temperature and can stick the upper layer and the lower layer together when heated to 50-200° C. Moreover, the fourth layer shall include a bottom layer of 2.0-10.0 mm thickness made from polymer har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com