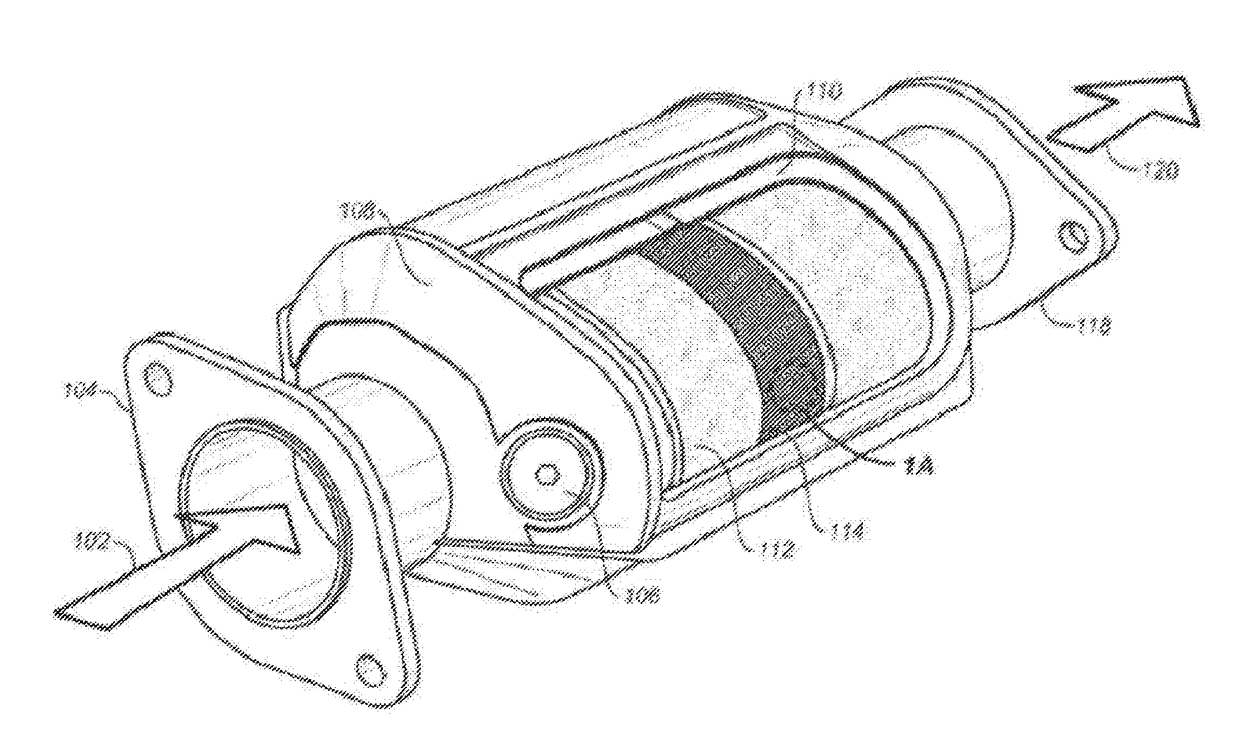

Compositions of lean NOX trap (LNT) systems and methods of making and using same

a technology of nox traps and compounds, applied in the field of catalysts, can solve the problems of high oxygen content, high loading of expensive pgms, and inhibition of the catalytic reduction of nosub>x

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Two-Layer Washcoat Configuration-Separate Oxidation and Reduction Washcoat Layers, Combined Reduction and NOx Storage Layer

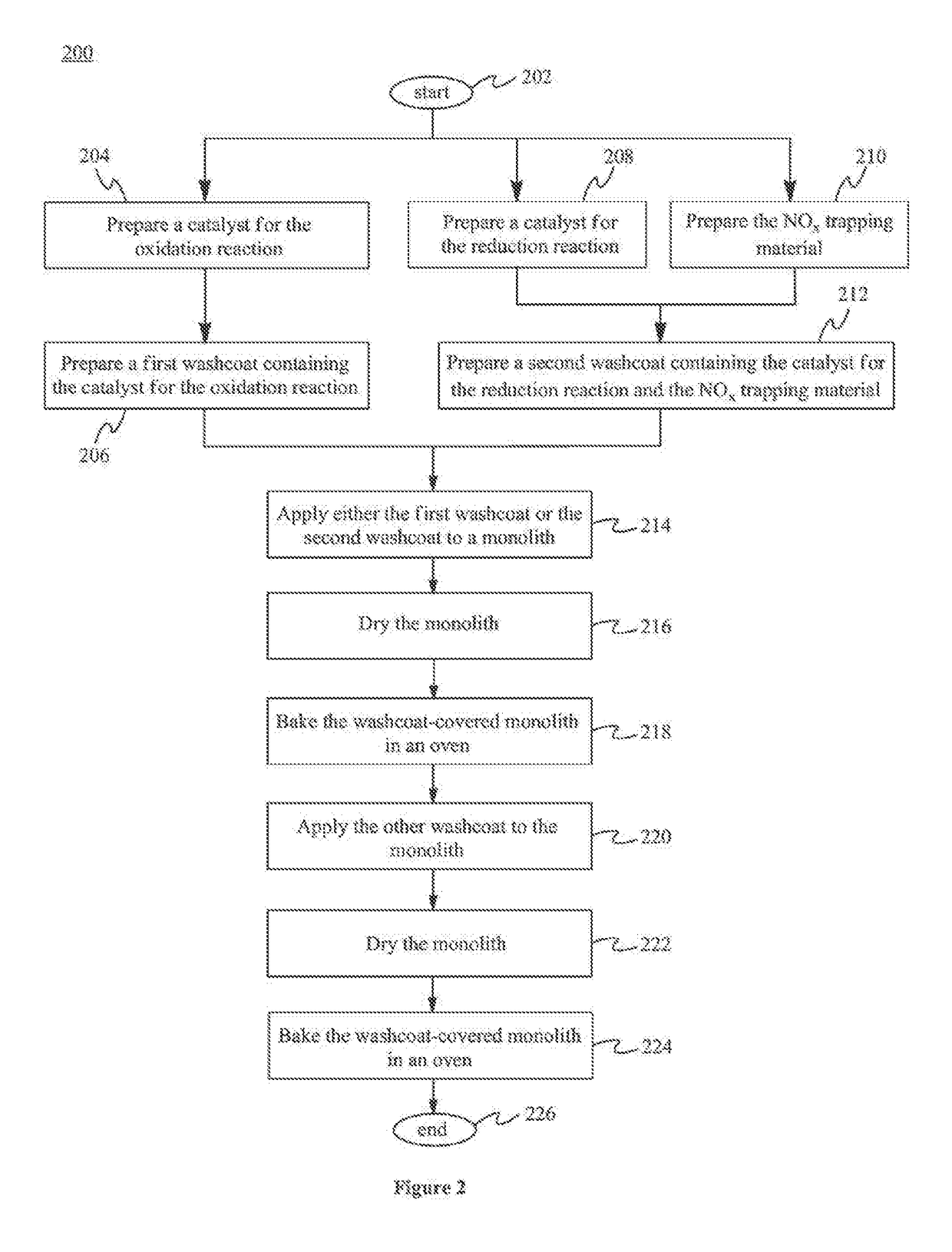

[1096](a) First Washcoat Composition: Approx. 85 g / L as follows:[1097]3% Boehmite;[1098]47% Porous alumina (MI-386 or the like), impregnated with 15% BaO;[1099]50% NNm powder (nano-on-nano-on-micro particle), the powder that contains Pt, Pd, or a mixture of Pt / Pd.[1100](b) Second Washcoat Composition: Approx. 326 g / L as follows:[1101]2% Boehmite;[1102]83% Cerium oxide (HSAS or the like), impregnated with 8% BaO and 0.6% Pt, Pd, or a mixture of Pt / Pd;[1103]15% NNm powder (nano-on-nano-on-micro particle), the powder that contains Rh.

[1104]Mix the washcoat ingredients from (a) with water and acetic acid and adjust the pH to about 4. After adjusting the viscosity to the proper levels, the washcoat is coated onto the substrate with an approximate layer thickness of 85 g / L. Excess washcoat is blown off and recycled. This first washcoat layer is then dried and calcined...

example 2

Three-layer Washcoat Configuration-Separate Oxidation and Reduction Washcoat Layers, Separate Reduction and NOx Storage Layer

[1105](a) First Washcoat Composition: Approx. 85 g / L as follows:[1106]3% Boehmite;[1107]47% Porous alumina (MI-386 or the like), impregnated with 15% BaO;[1108]50% NNm powder (nano-on-nano-on-micro particle), the powder that contains Pt, Pd, or a mixture of Pt / Pd.[1109](b) Second Washcoat Composition: Approx. 75 g / L as follows:[1110]3% Boehmite;[1111]17% Porous alumina (MI-386 or the like);[1112]80% NNm powder (nano-on-nano-on-micro particle), the powder that contains Rh.[1113](c) Third Washcoat Composition: Approx. 275 g / L as follows:[1114]4% Boehmite;[1115]73% Cerium oxide (HSAS or the like), impregnated with 8% BaO;[1116]23% NNm powder (nano-on-nano-on-micro particle), the powder that contains Pt, Pd, or Pt / Pd.

[1117]Mix the washcoat ingredients from (a) with water and acetic acid and adjust the pH to about 4. After adjusting the viscosity to the proper leve...

example 3

Comparison of Catalytic Converter Performance Described Herein to Commercially Available Catalytic Converters

[1118]FIG. 4 illustrates the performance of a coated substrate with reduced PGM in the NOx storage layer component of a catalytic converter (indicated as “PGM-reduced LNT”), and a coated substrate with no PGM in the NOx storage layer component of a catalytic converter (indicated as “PGM-free LNT”), where the coated substrates are prepared according to embodiments of the present invention, compared to a commercially available catalytic converter (indicated as “reference”). The catalysts were artificially aged at 750° C. for 25 hours to simulate operation after 125,000 miles in a car.

[1119]The commercially available coated substrate displays a CO light-off temperature of 113° C. The coated substrate with the reduced PGM loading in the NOx storage layer washcoat displays a CO light-off temperature of 107° C., or about 6° C. lower than the commercially available coated substrate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com