Biocompatible material in granules made of metal material or metal alloys and use of said granules for vertebroplasty

a biocompatible metal and granule technology, applied in the field of transcutaneous vertebroplasty or kyphoplasty surgery, can solve the problems of high exothermicity, high development of heat generated by polymerization reaction, and localised bone necrosis problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

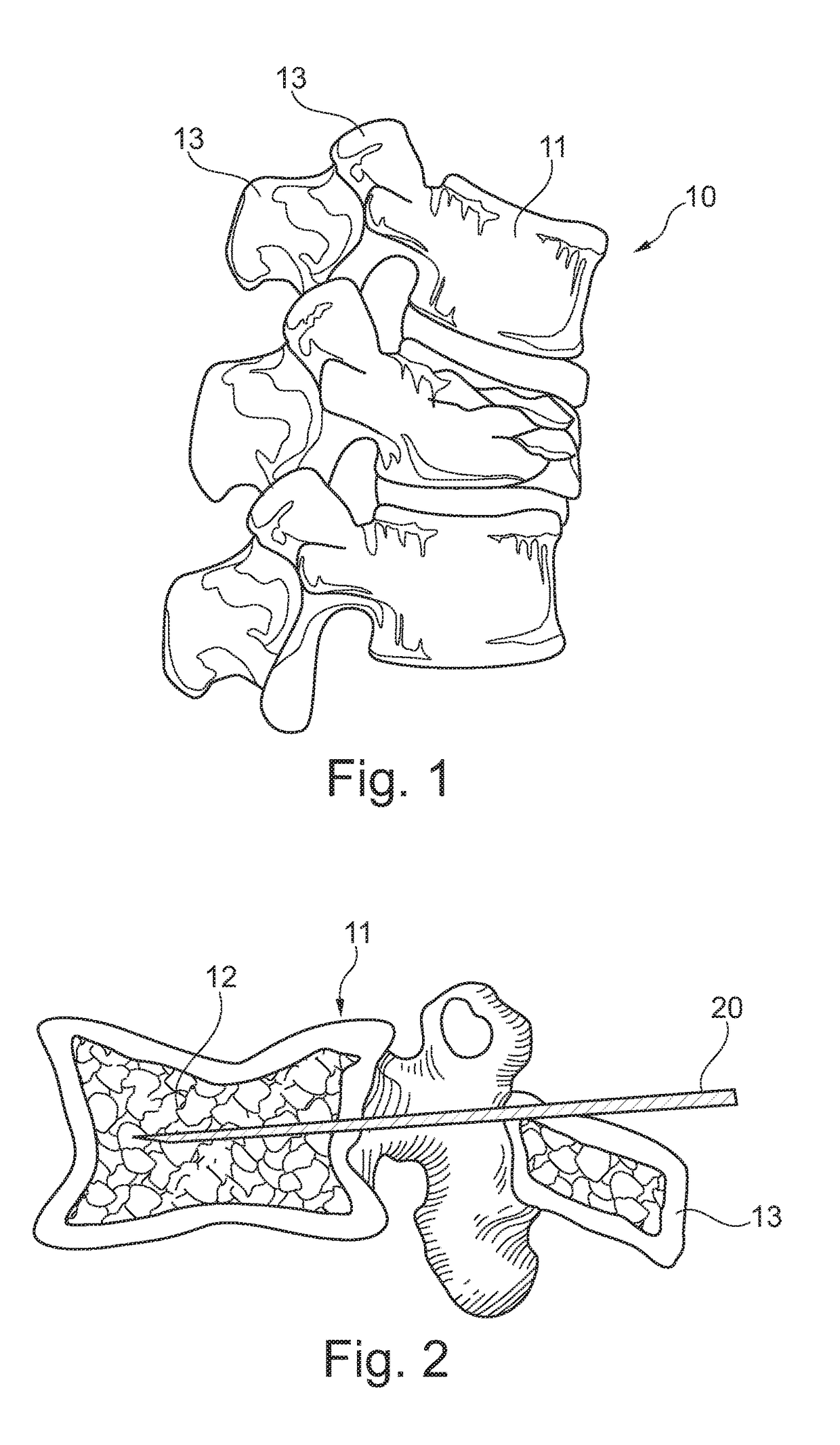

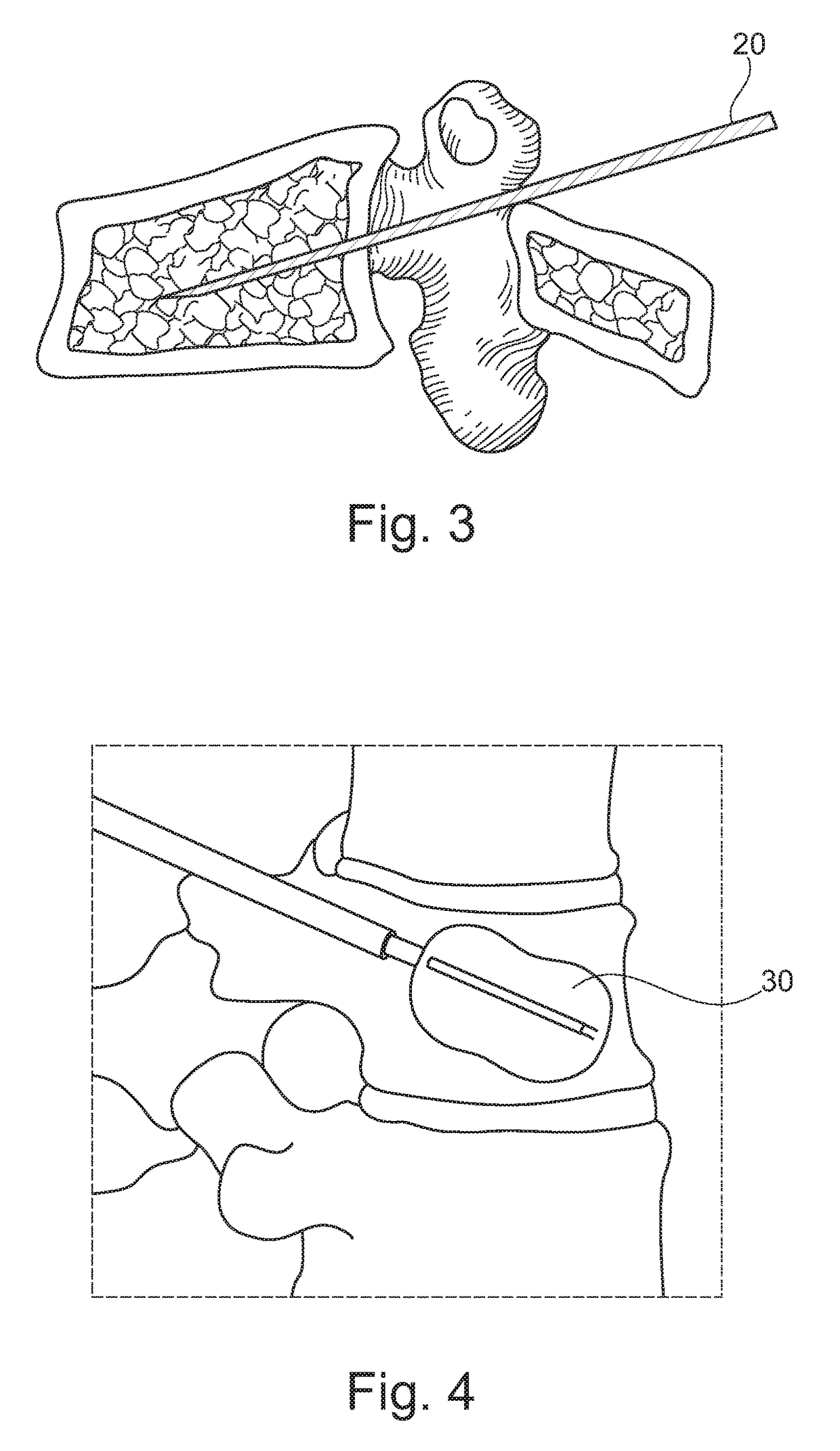

[0034]According to the present invention, granules made of biocompatible metal material, more particularly based on titanium and / or its alloys, are produced with characteristics such as to make the insertion of granules and osseointegration, once in place, simultaneously possible during the surgical phase.

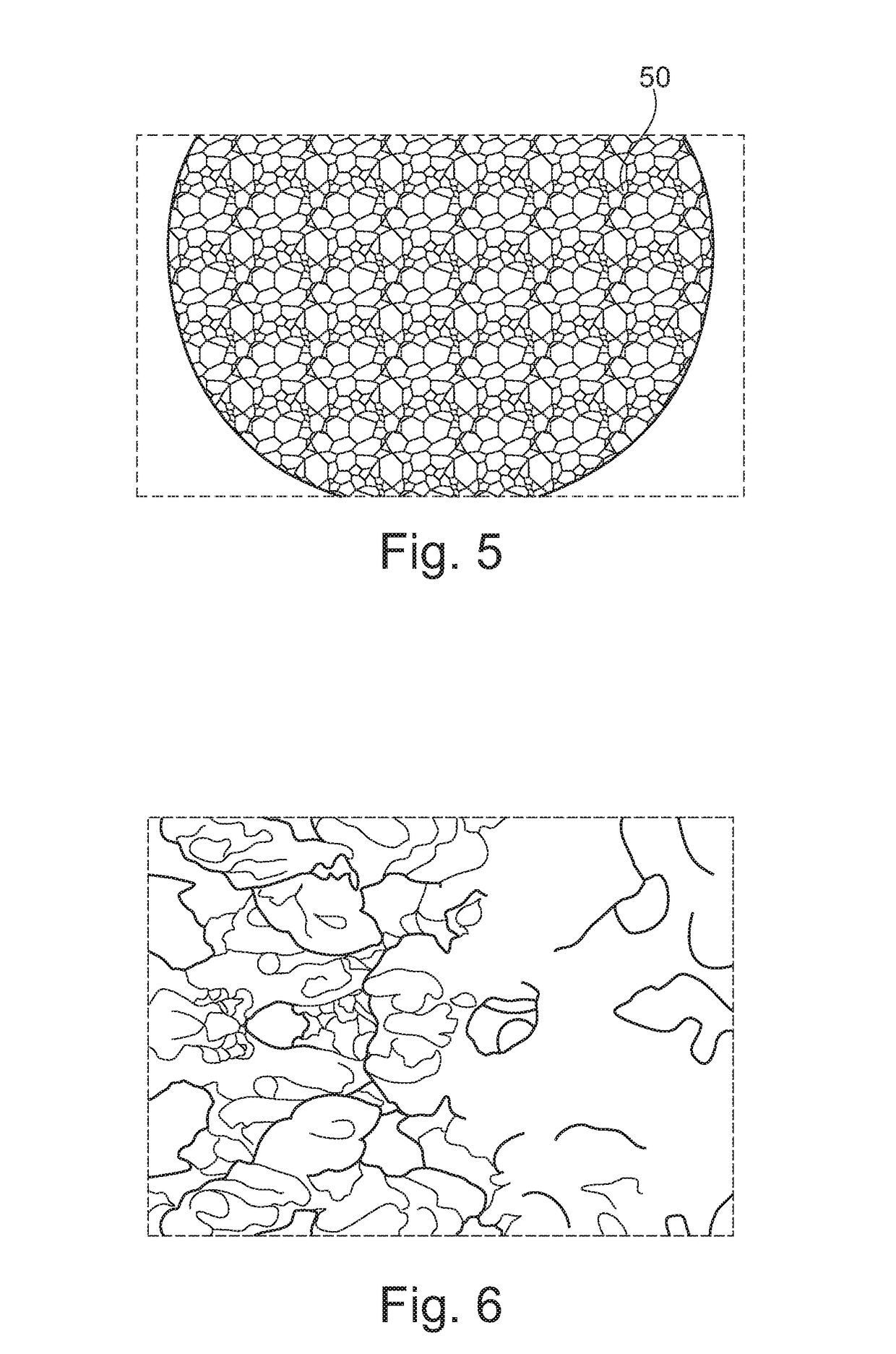

[0035]The term “granules” is used in the present description to indicate solid particles having any geometry whatsoever, preferably, but not exclusively an approximately spherical geometry, and having average size of the order of a few millimetres, preferably less than 7 mm, even more preferably but not necessarily between 4 and 6 mm.

[0036]In the case in which these granules have a spherical geometry, they will be characterized by an outer diameter of a few millimetres, preferably less than 7 mm, more preferably but not necessarily between 4 and 6 mm.

[0037]According to a preferred embodiment of the present invention, said granules will have spherical shape, in particular they will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore diameter | aaaaa | aaaaa |

| pore diameter | aaaaa | aaaaa |

| pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com