Controlling dry etch process characteristics using waferless dry clean optical emission spectroscopy

a technology of optical emission spectroscopy and control process, which is applied in the direction of hollow article cleaning, plasma technique, and test/measurement of semiconductor/solid-state devices, etc., can solve the problems of device failure, defect generation and device variation of the etch profile, and reduce the variation of the dry etch wafer-to-wafer process, and minimize the accumulation of deposition. , the effect of improving the control of the etch wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

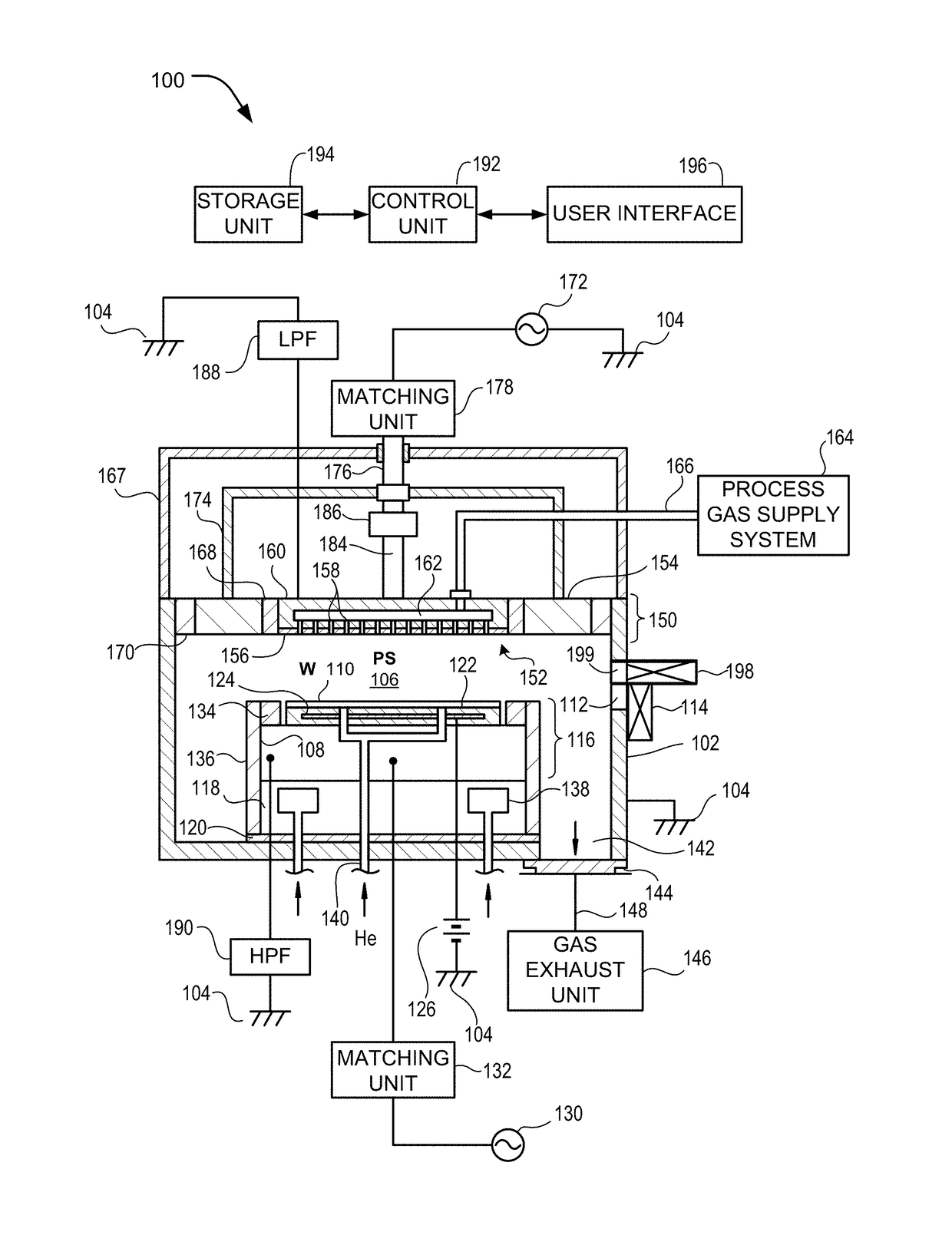

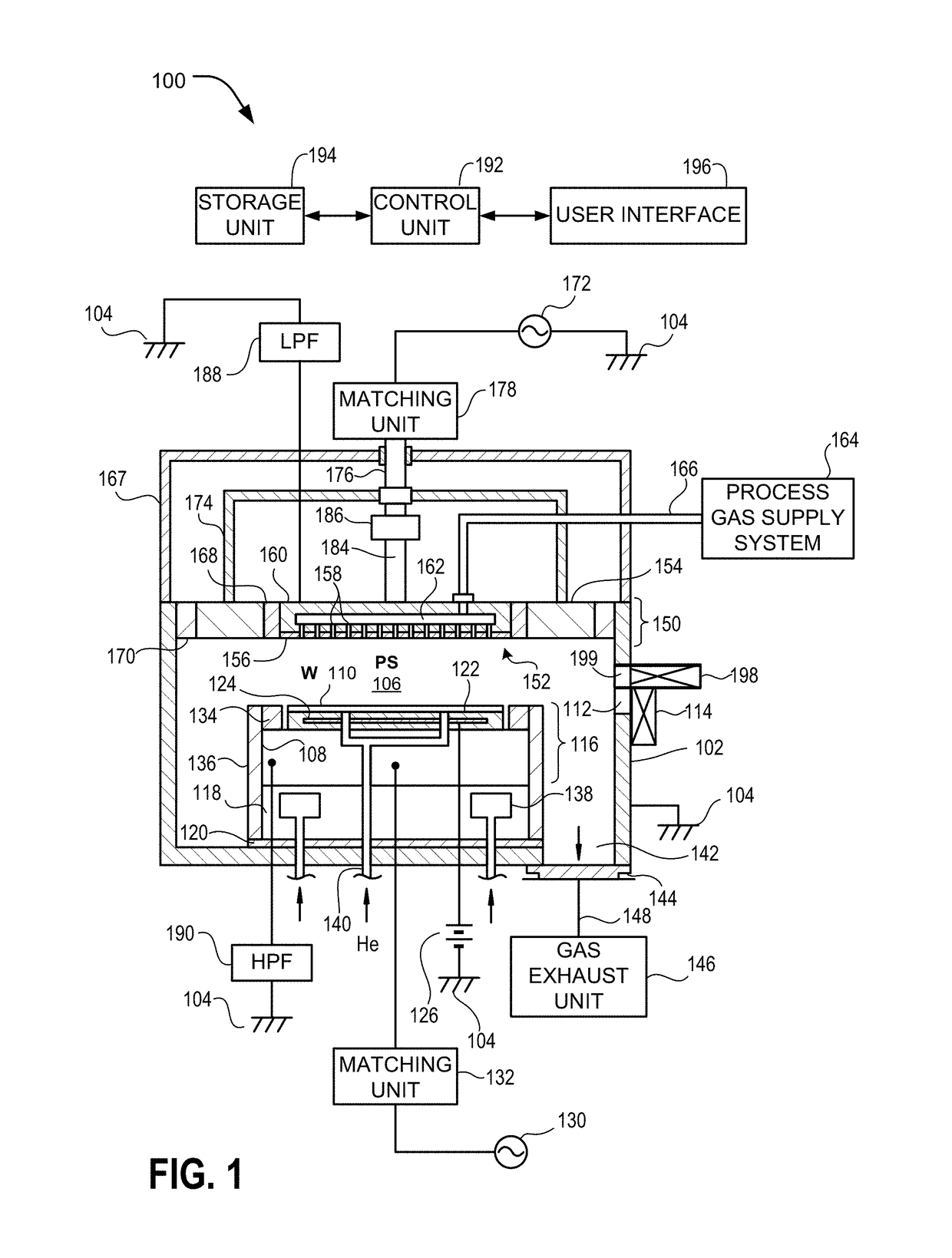

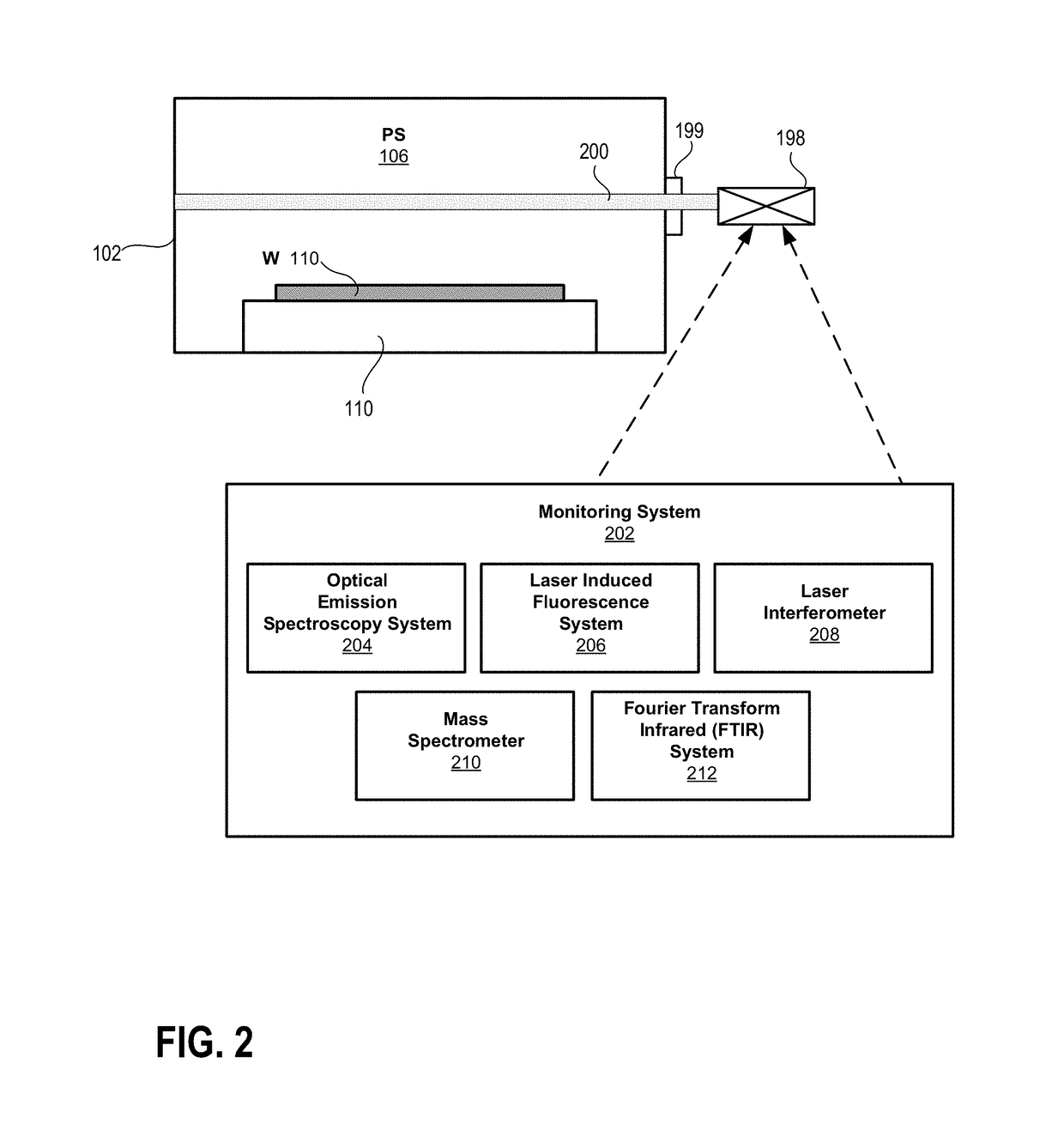

[0012]Described herein are architectures, platforms and methods for analyzing residue constituents in a waferless dry clean (WLDC) process, and in particular analysis using Optical Emission Spectroscopy (OES). A process control monitor / metric such as OES can be utilized to analyze the effectiveness of a WLDC process by evaluation of carbon (C) and fluorine (F) based wavelengths in the spectra for a batch of wafers.

[0013]Moreover, a WLDC process can be optimized based on OES spectra of undesirable residue constituents being removed by the dry cleaning process following one particular device wafer process. Typically, an ineffective WLDC process will never show the leveling out in OES intensity for the wavelength examined of a constituent that is intended to be removed by the WLDC. However, the OES spectra of this constituent would show the leveling out in intensity once the endpoint was reached for the WLDC process; this endpoint time can be utilized for determining the ideal completi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com