Heat Pipe with Inner Zeolite Coated Structure

a technology of heat pipe and inner zeolite, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of wicks being easily oxidized, failure, and only transferring heat upwards, and achieves maximum evaporation heat transfer capability and capillary force. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The following description of the preferred embodiment is provided to understand the features and the structures of the present invention.

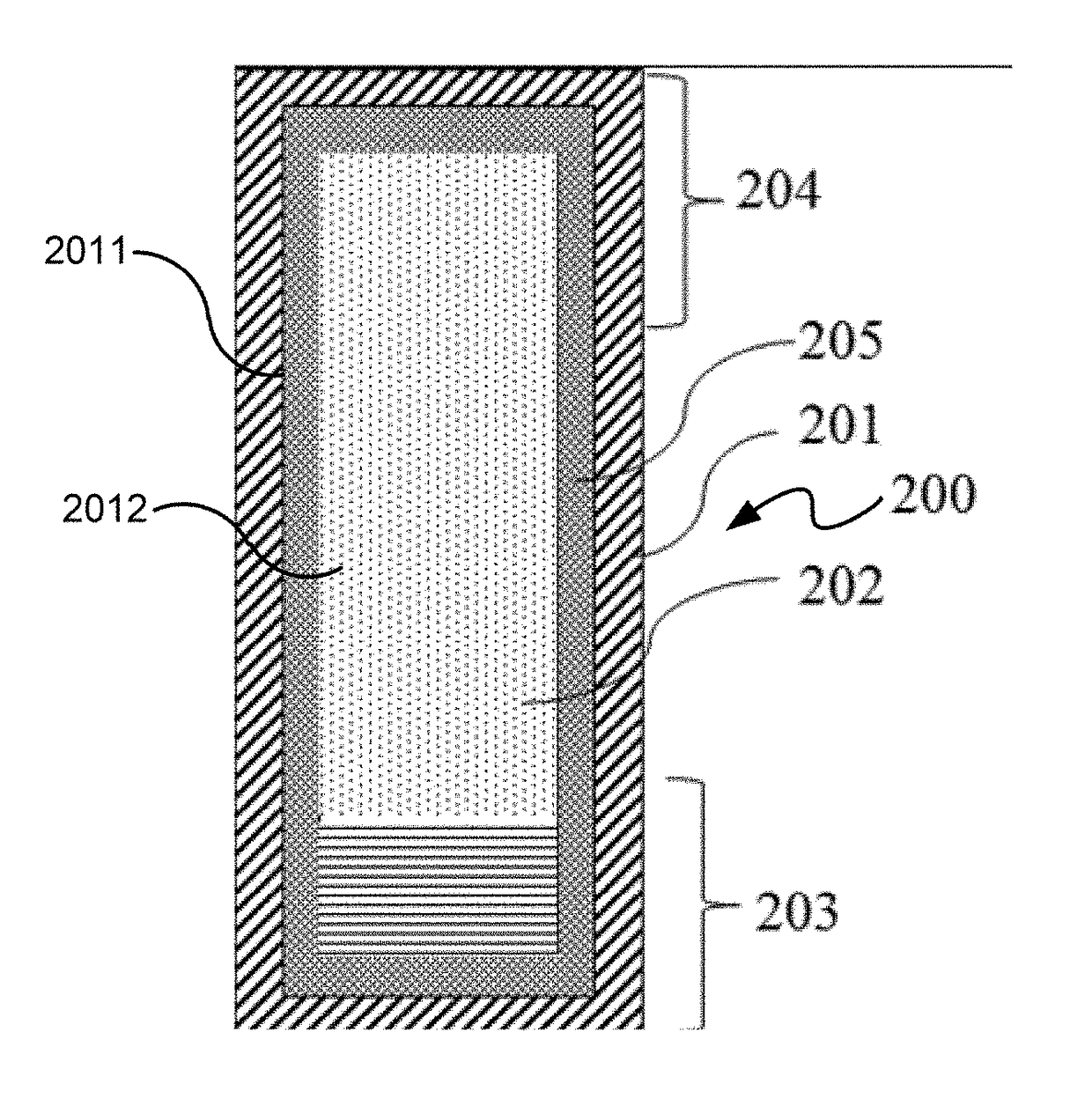

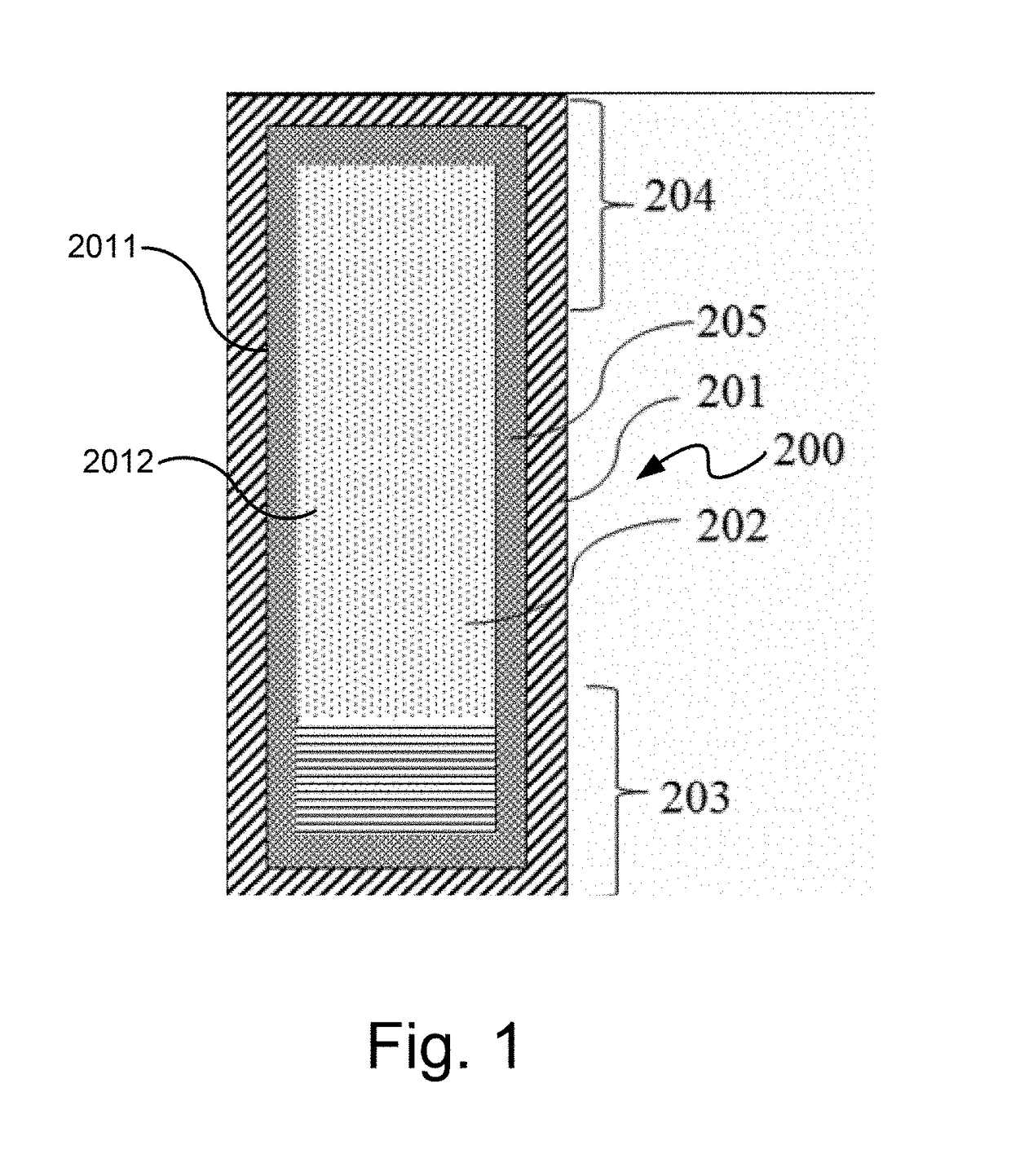

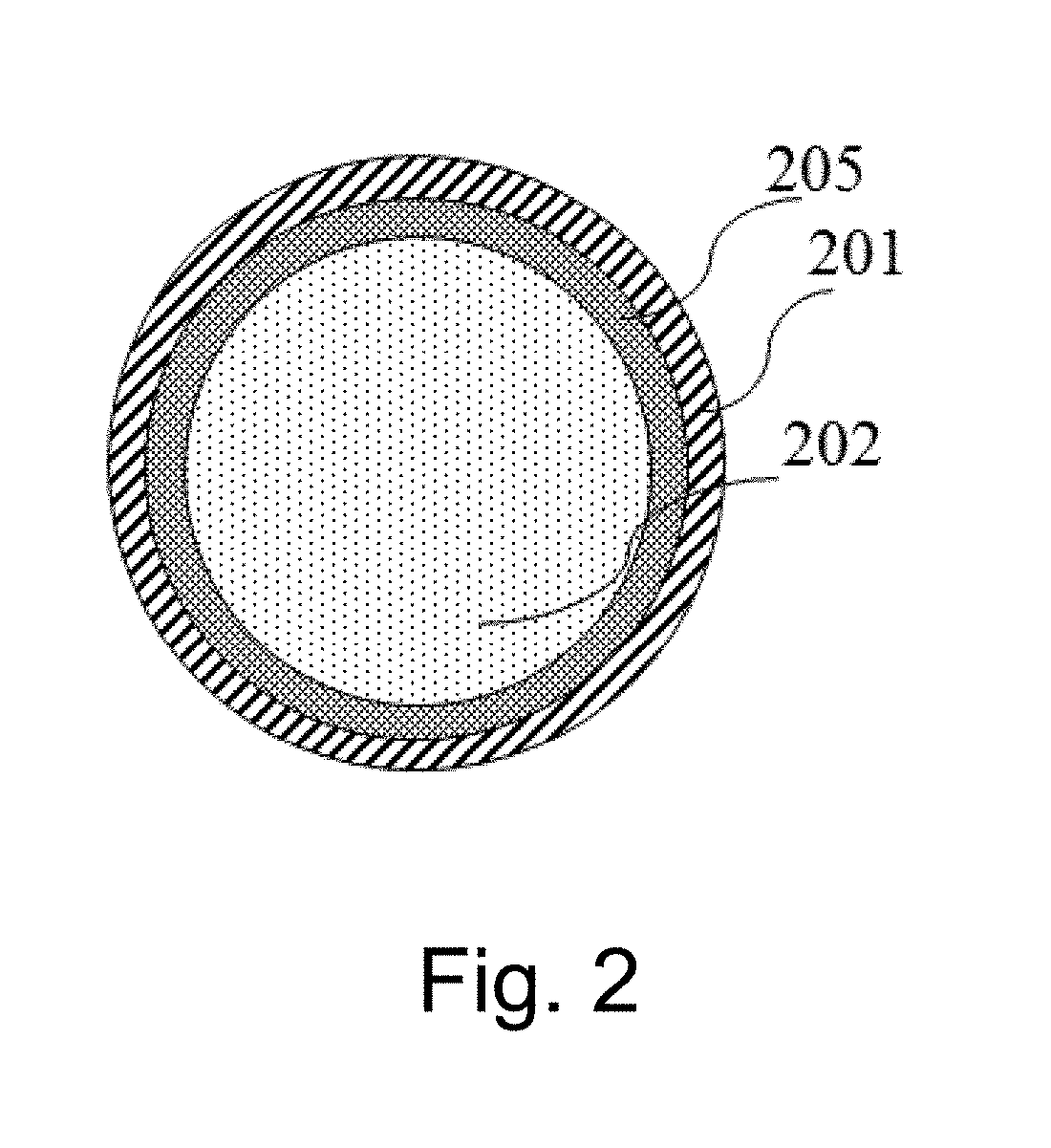

[0019]Please refer to FIG. 1˜FIG. 6, which are a vertical cross-sectional view showing a preferred embodiment according to the present invention; horizontal cross-sectional views showing a zeolite single-layer coating and a zeolite dual-layer coating; a flow block diagram showing fabrication of the present invention; a cross-sectional view showing a zeolite coating on surface of micro grooves; and a view showing zeolite crystals. As shown in the figures, the present invention is a heat pipe 200 for cooling or recycling waste heat with high efficiency, comprising a shell 201, and a zeolite coating 205.

[0020]The shell 201 has an evaporator section 203 and a condenser section 204 located away from the evaporator section 203. The shell 201 has an inner surface 2011. The inner surface 2011 surrounds an enclosed chamber 2012. The enclosed chamber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com