Method for Coating a Substrate and Metal Alloy Vacuum Deposition Facility

a vacuum deposition facility and substrate technology, applied in vacuum evaporation coating, chemical vapor deposition coating, coatings, etc., can solve the problems of difficult industrial implementation of this process, inconceivable, complicated and expensive subsequent diffusion heat treatment, etc., and achieve simple industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

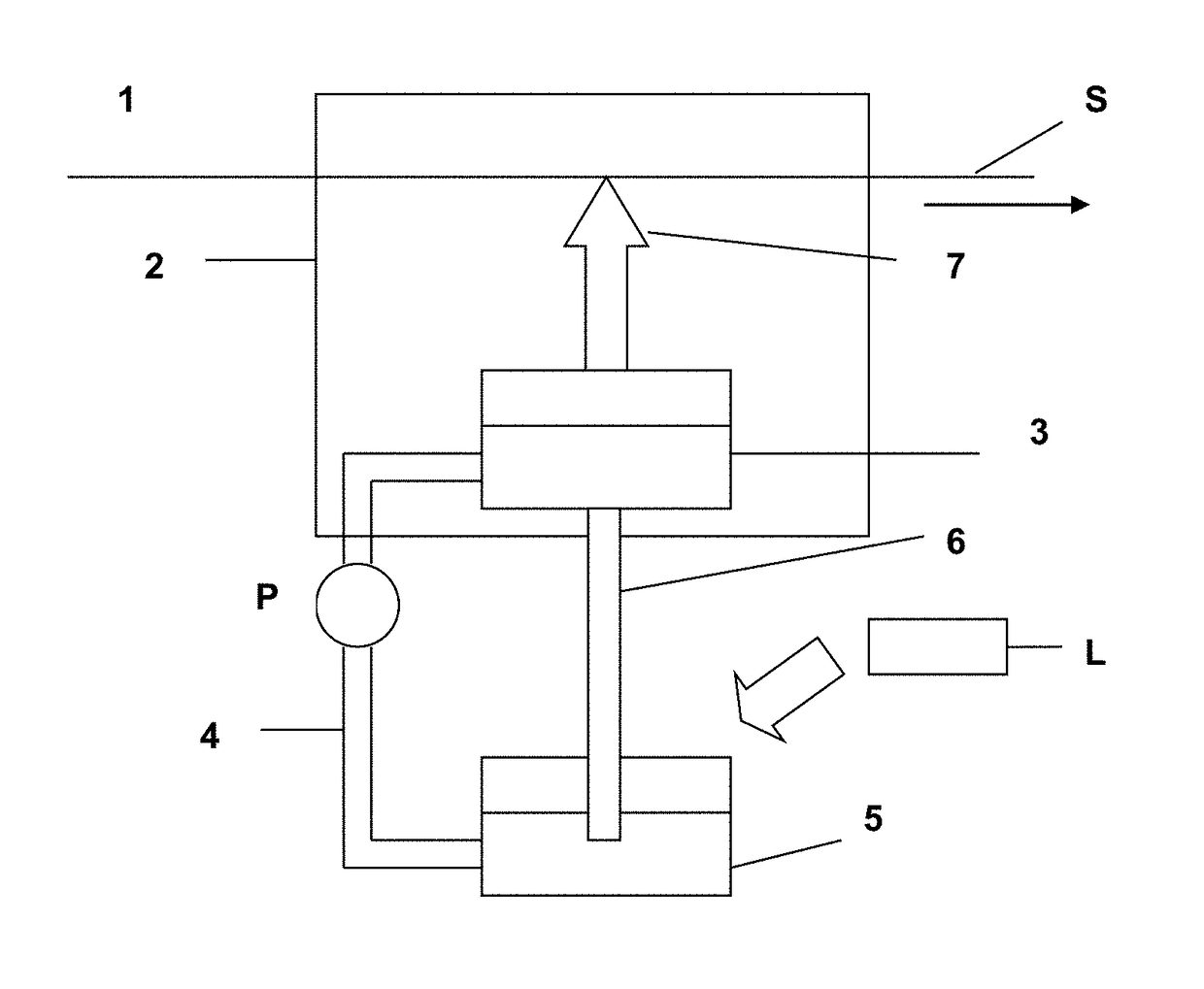

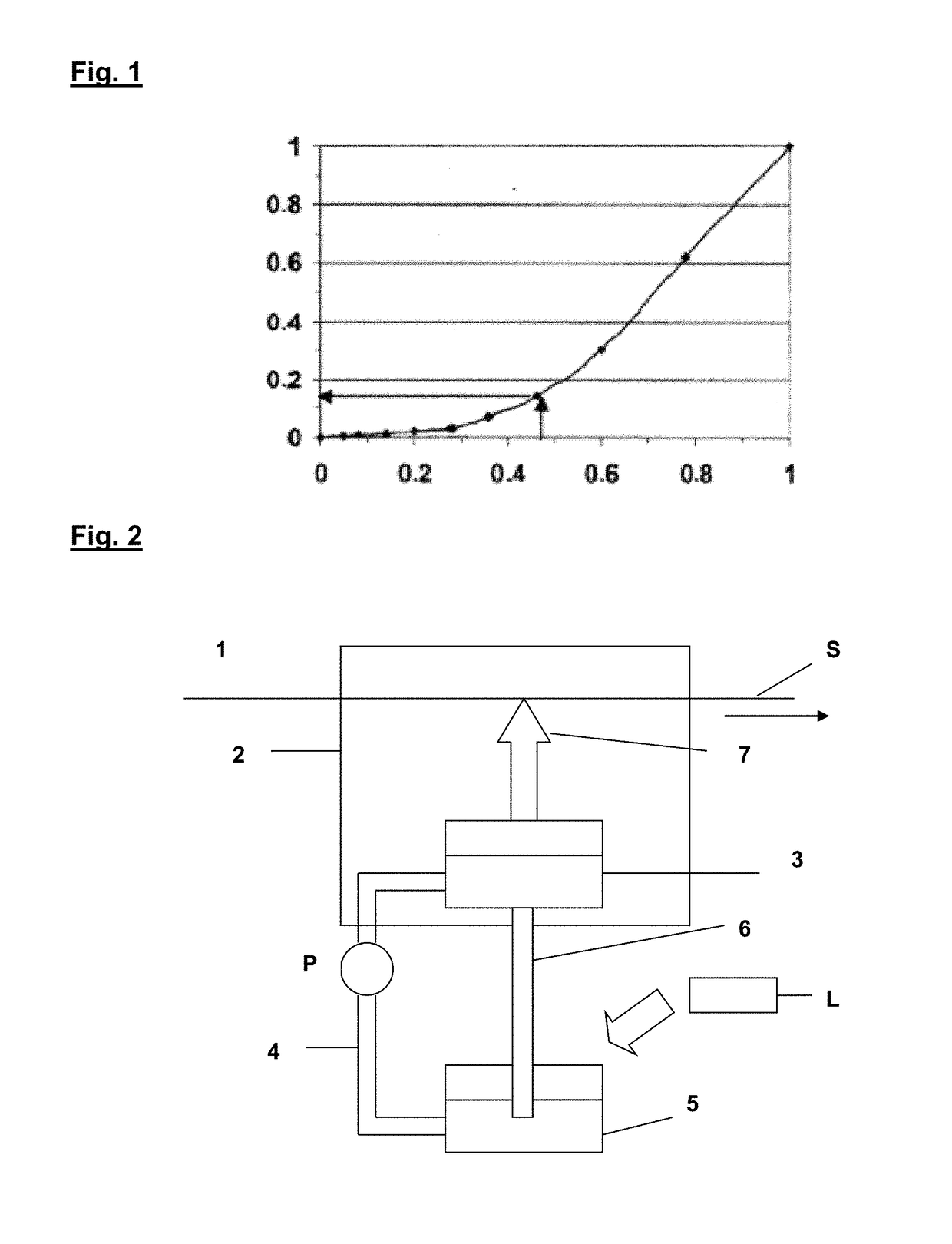

[0050]a facility according to the invention is shown more particularly in FIG. 2, which shows a facility 1 comprising a vacuum deposition chamber 2. This chamber 2 is preferably kept at a pressure of between 10−8 and 10−4 bar, for example. It has an entry load-lock and a exit load-lock between which a substrate S, such as for example a steel strip, runs.

[0051]The substrate S may be made to run by any suitable means, depending on the nature and the shape of said substrate. A rotary support roller on which a steel strip can bear may in particular be used.

[0052]Placed opposite the face of the substrate S which has to be coated there is a small extraction chamber 7 provided with a narrow slot, the length of which is close to the width of the substrate to be coated. This chamber may for example be made of graphite and may be mounted, directly or otherwise, on an evaporation crucible 3 that contains the liquid metal to be deposited on the substrate S. The evaporation crucible 3 is continu...

second embodiment

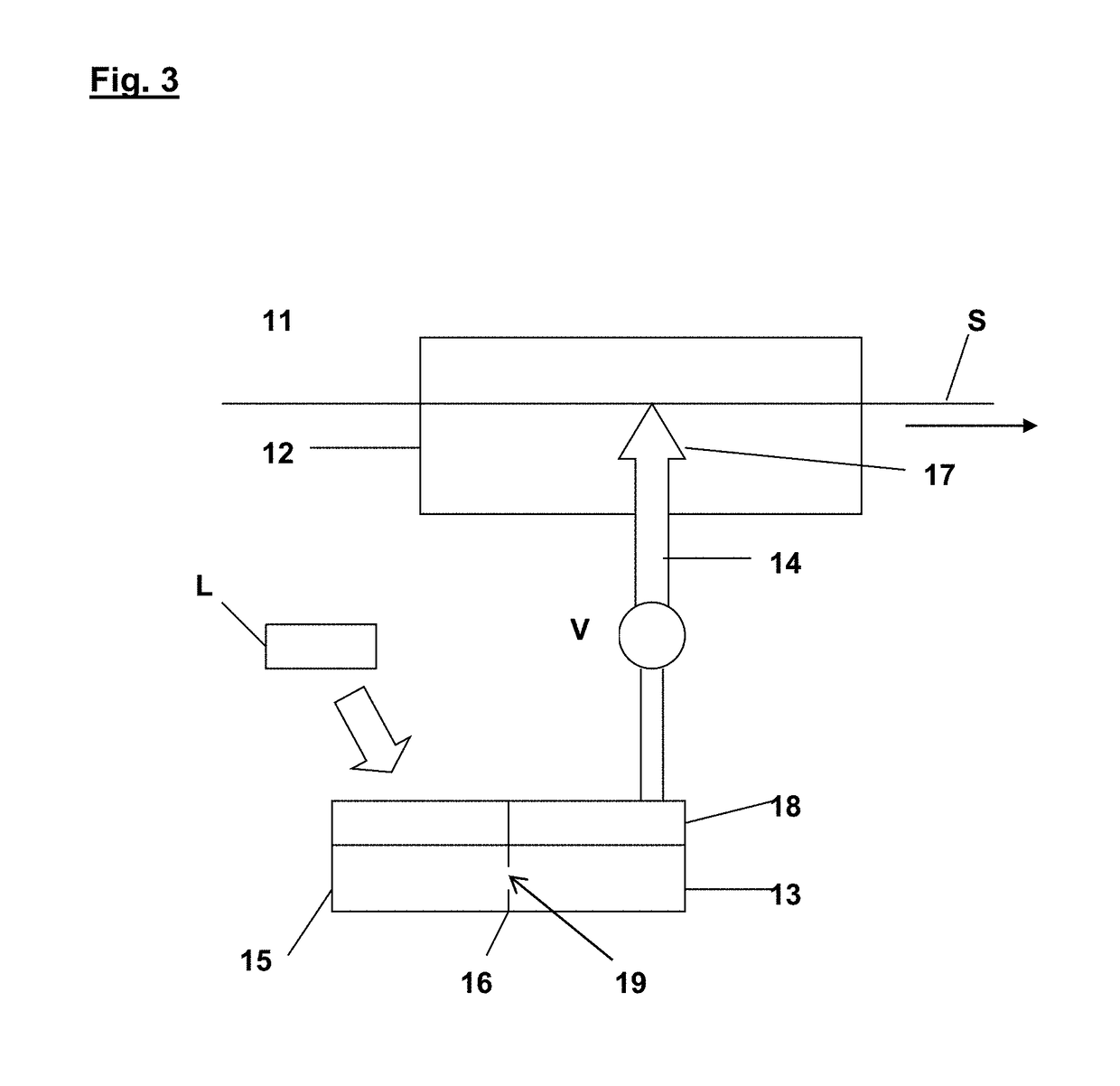

[0060]In a second embodiment as shown in FIG. 3, a facility 11 comprises a vacuum deposition chamber 12 similar to the chamber 2. An evaporation crucible 13 is placed under the vacuum chamber 12 and is connected via a pipe 14 thereto.

[0061]A recharging furnace 15 is placed alongside the evaporation crucible 13, the two components sharing a common wall 16 pierced by a communication opening 19 placed below the level of the metal alloy bath but above the bottom of these components so as to prevent any impurities that settle at the bottom of the recharging furnace 15 from being introduced into the evaporation crucible 13.

[0062]The evaporation crucible 13 is moreover placed in a confined chamber 18, placed outside the vacuum chamber 12.

[0063]The pipe 14 feeds a JVD coater 17, similar to the coater 7.

[0064]In the same way as described above with respect to FIG. 2, the composition of the coating which it is desired to obtain on the substrate is first determined and then deduced from this i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com