Induction of gene expression using a high concentration sugar mixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

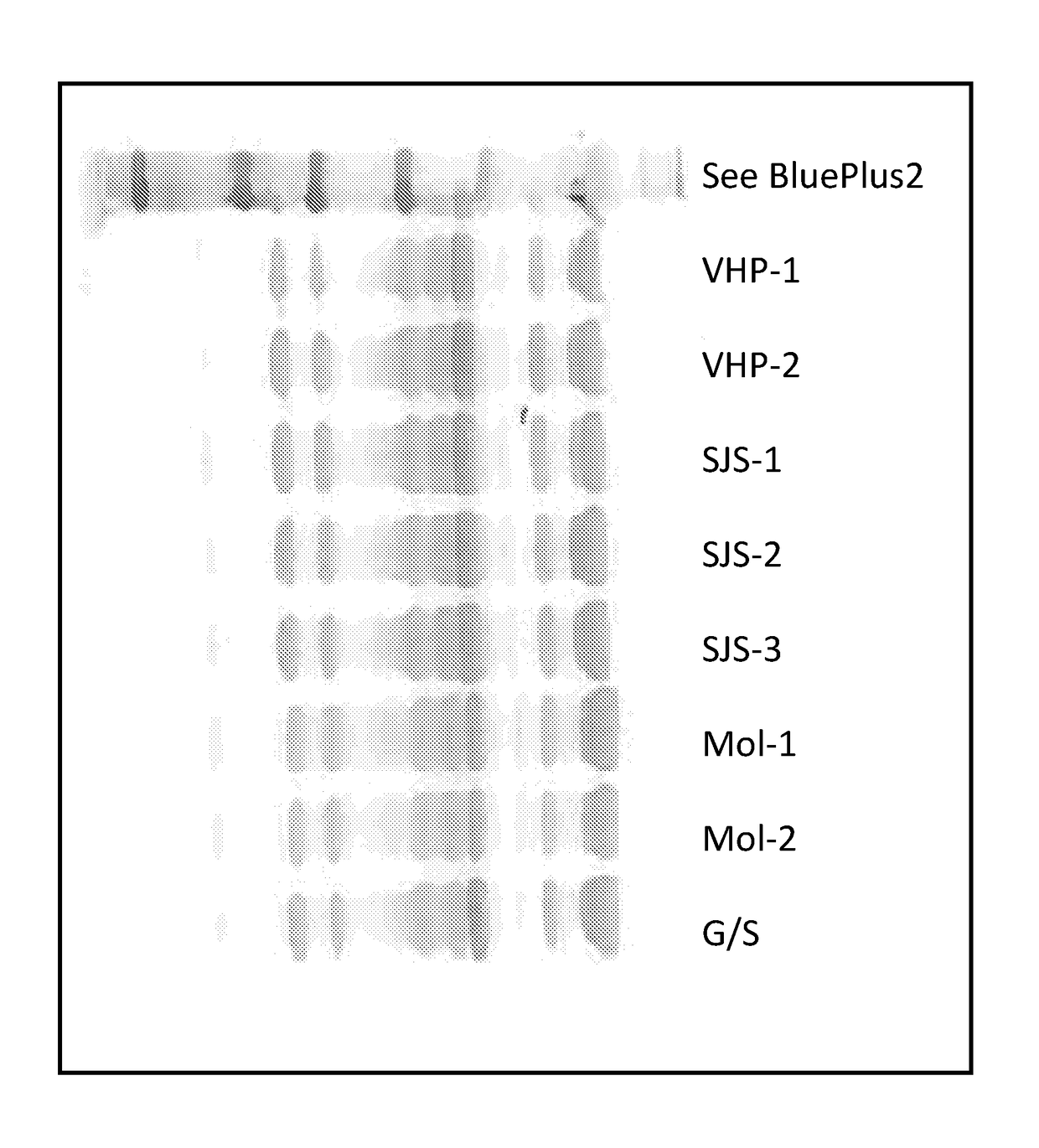

Image

Examples

example 1

Glucose / Sophorose (G / S) Control Fermentation

[0178]The glucose / sophorose solution for induction of a control T. reesei protein production fermentation was prepared as previously described, in, for example, U.S. Pat. No. 7,713,725. The glucose / sophorose preparation was diluted to match the sugar solids content of the sucrose feeds. Solids content was 55%.

[0179]A typical industrial scale Trichoderma reesei fermentation process comprises two phases. First phase is the biomass growth phase, with little to no protein production; followed by the protein production phase, with little to no biomass growth. During the second phase, the rate of protein production is, in normal circumstances, linear. The protein production rate is the average rate from the start of the production phase to the end of the run. The yield calculation is the amount of protein produced during the protein production phase divided by the amount of sugars consumed during the same time period. Total protein in fermentati...

example 2

Sugarcane Juice Syrup (SJS) Fermentation

[0181]Sugarcane juice syrup (sucrose) was inverted and reverted, and the resulting syrup was fed to T. reesei protein production fermentations. The results were compared to the control fermentation of the same strain, fed glucose / sophorose.

[0182]Three replicate fermentations were run using inverted and reverted Sugarcane Juice Syrup. Inversion was carried out at 75° C. and pH 2.0 for 4 hrs, followed by reversion for 48 hours at pH 4.0 and 60° C. with T. reesei beta-glucosidase (Bgl1) included at a concentration of 64,000 U / kg syrup. Alternatively inversion may be carried out employing a suitable invertase enzymes, for example, one derived from Aspergillus niger (UniPro Accession Number: QOZR36), Aspergillus fumigates, Aspergillus japonicas, Aspergillus nidulans, or other Aspergillus spp, or one derived from Fusarium oxyporum, or other like fungal species, as well as from various bacterial or even plant sources. The inversion reaction may be ca...

example 3

Very High Purity Sucrose (VHP) Fermentation

[0185]Very high purity (VHP) sucrose was inverted and reverted, and the resulting sugars fed to T. reesei protein production fermentations. The results were compared to the control fermentation of the same strain, fed glucose / sophorose.

[0186]Duplicate fermentations of T. reesei using the inverted and reverted VHP sucrose feed were performed. Inversion was carried out at 75° C. and pH 2.0 for 4 hrs, followed by reversion for 48 hours at pH 4.0 and 60° C. with T. reesei beta-glucosidase (Bgl1) included at a concentration of 64,000 U / kg syrup.

[0187]The total solids content of the VHP feed was 55%. A control fermentation was run in which the VHP inversion was conducted, but the reversion was omitted.

[0188]One of the VHP duplicate fermentations showed contamination in the final two time point samples. This did not appear to have a major effect on the performance. Yield was reduced by 3% relative to the non-contaminated run and rate was reduced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com