High-frequency module

a high-frequency module and module technology, applied in the direction of printed circuit manufacturing, cross-talk/noise/interference reduction, printed circuit aspects, etc., can solve the problem of wiring substrate cracking or warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

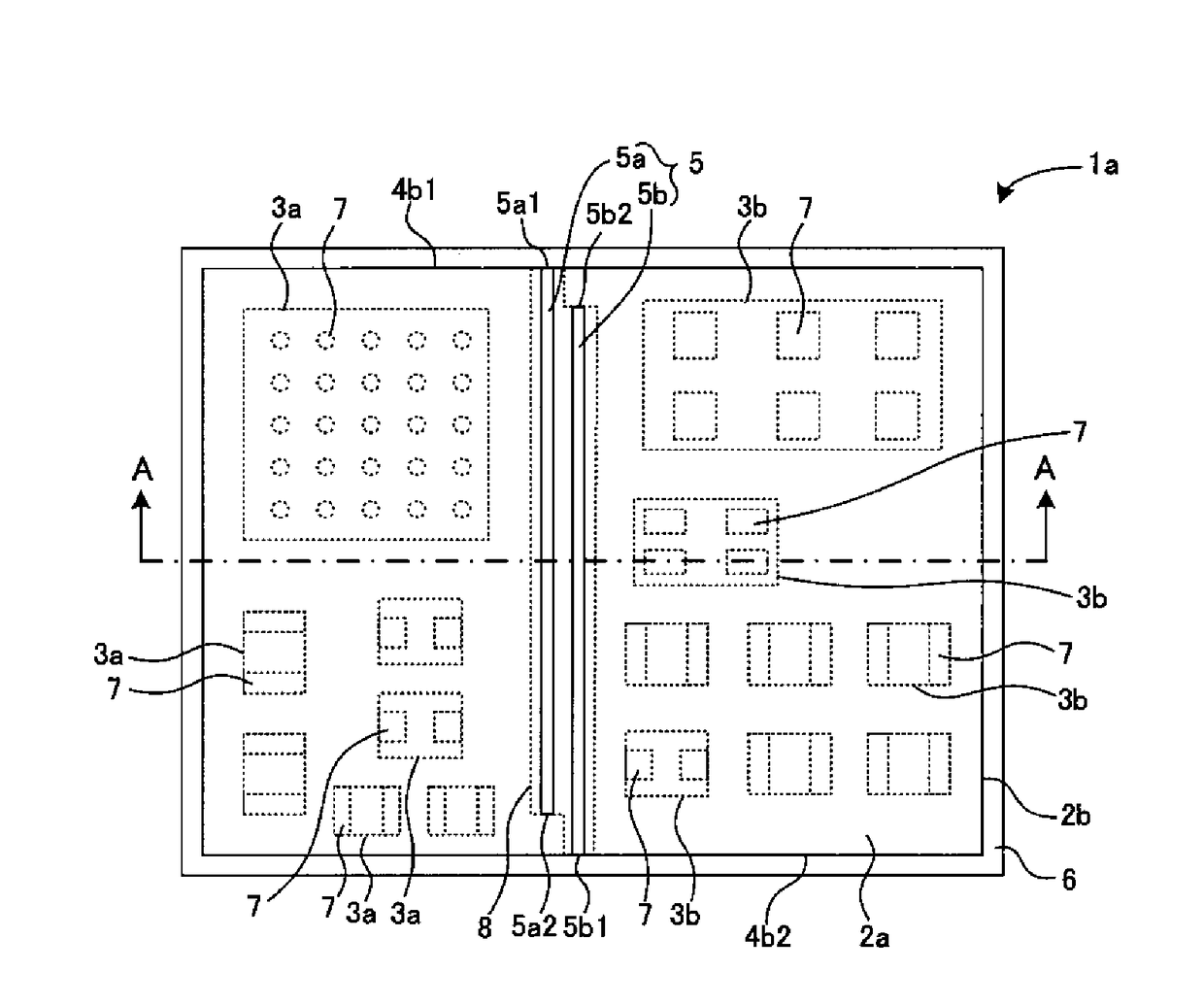

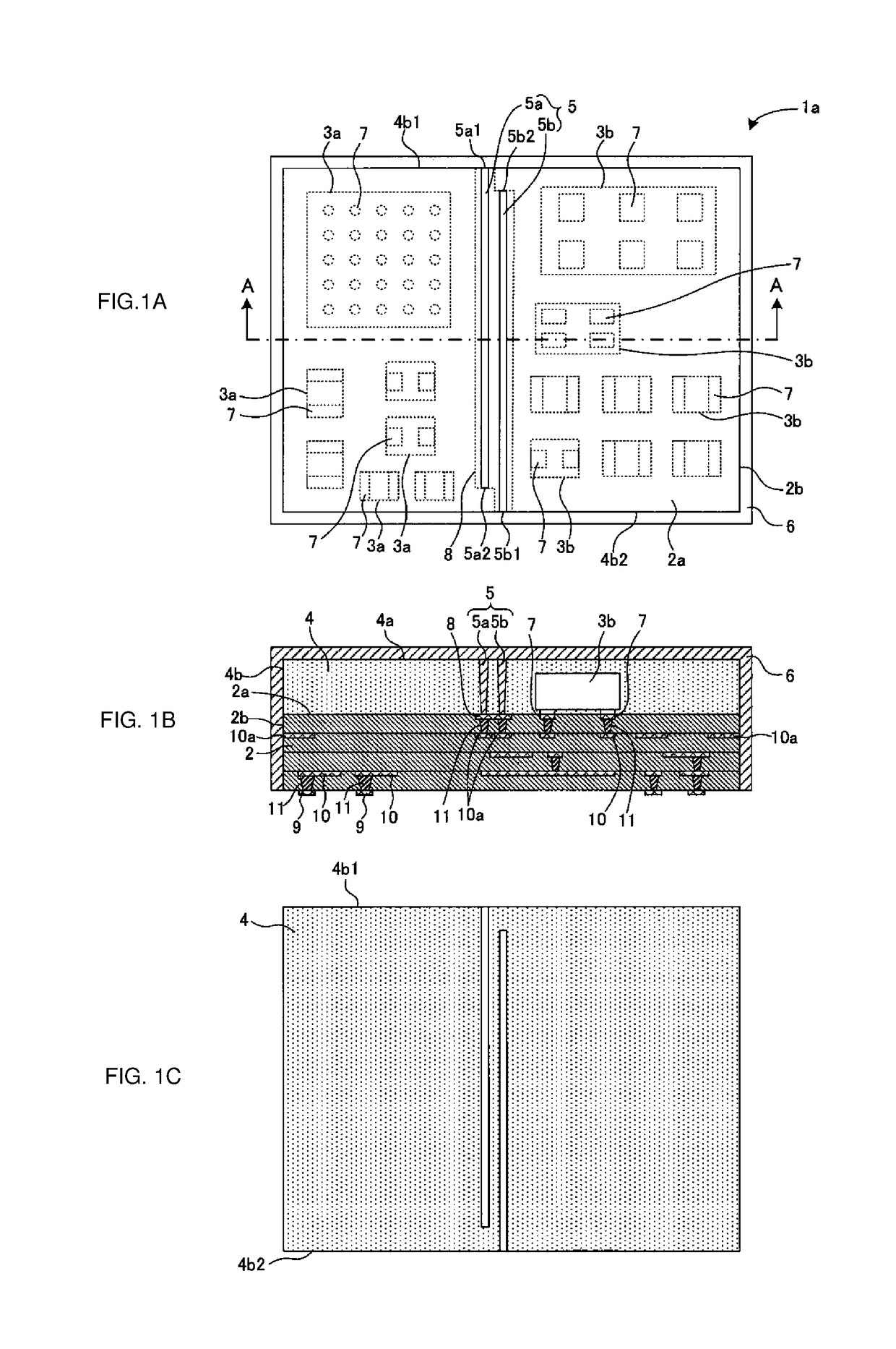

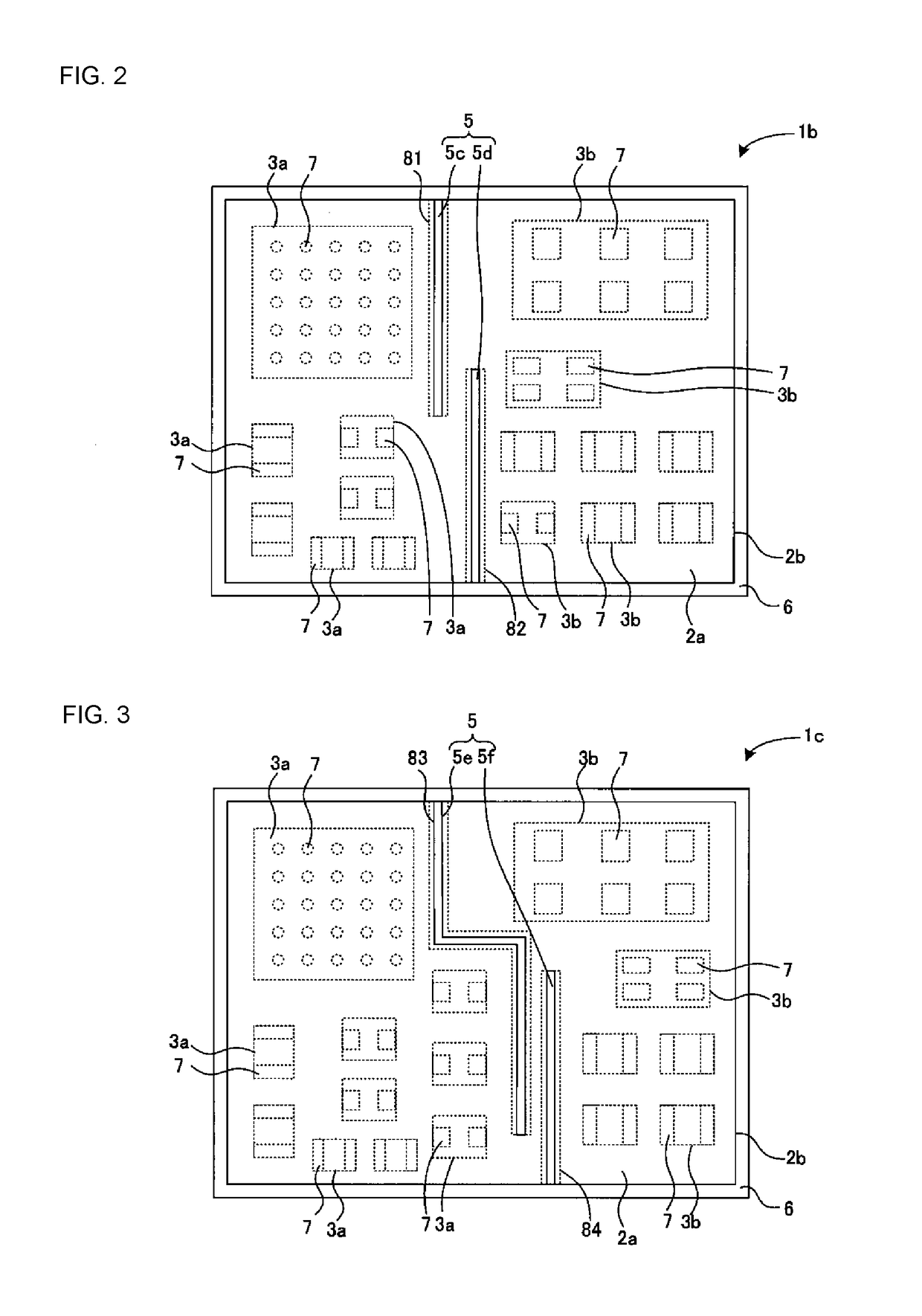

[0031]A high-frequency module la according to a first embodiment of the present disclosure will be described while referring to FIGS. 1A, 1B and 1C. FIG. 1A is a plan view of the high-frequency module 1a, FIG. 1B is a sectional view taken along A-A in FIG. 1A and looking in the direction of the arrows, and FIG. 1C is a plan view of a sealing resin layer 4. In addition, a top surface part of a shield film 6 is not illustrated in FIGS. 1A, 1B and 1C.

[0032]As illustrated in FIGS. 1A, 1B and 1C, the high-frequency module 1a according to this embodiment includes a wiring substrate 2, a plurality of components 3a and 3b that are mounted on an upper surface 2a (corresponding to “a main surface of the wiring substrate” of the present disclosure) of the wiring substrate 2, a sealing resin layer 4 that is stacked on the upper surface 2a of the wiring substrate 2, a shield film 6 that covers a surface of the sealing resin layer 4, and a shield wall 5 that is provided in the sealing resin layer...

second embodiment

[0059]A high-frequency module 1d according to a second embodiment of the present disclosure will be described while referring to FIGS. 4A and 4B. FIG. 4A is a plan view of the high-frequency module 1d, and FIG. 4B is a sectional view taken along B-B in FIG. 4A and looking in the direction of the arrows. In addition, a top surface part of the shield film 6 is not illustrated in FIG. 4A.

[0060]The high-frequency module 1d according to this embodiment differs from the high-frequency module la of the first embodiment described while referring to FIGS. 1A, 1B and 1C in that the area of the upper surface 2a of the wiring substrate 2 is partitioned into one central island-shaped region 2a1 and a remaining region 2a2 by a shield wall element body 51 that is substantially U-shaped in a plan view and a shield wall element body 52 that is substantially L-shaped in a plan view. The rest of the configuration is the same as that of the high-frequency module 1a of the first embodiment and therefore...

third embodiment

[0070]A high-frequency module 1g according to a third embodiment of the present disclosure will be described while referring to FIG. 8. FIG. 8 is a plan view of the high-frequency module 1g, and is a diagram corresponding to each of FIGS. 4A and 4B.

[0071]The high-frequency module 1g according to this embodiment differs from the high-frequency module 1e of the modification of the second embodiment described while referring to FIG. 6 in that, as illustrated in FIG. 8, the upper surface 4a and the peripheral side surfaces 4b of the sealing resin layer 4 and the side surfaces 2b of the wiring substrate 2 are covered by a shield film 61 having an opening 12 in a part thereof that is superposed in a plan view with the island-shaped region 2a3. The rest of the configuration is the same as that of the high-frequency module 1e, and therefore the same symbols are used and the description thereof is omitted.

[0072]Furthermore, as illustrated in FIG. 9, a ground electrode 10a1 that is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com