Multilayer insulating panel for the installation of an electric heating system in subfloors or walls

a multi-layer, insulating panel technology, applied in the direction of lighting and heating apparatus, heating types, other domestic objects, etc., can solve the problems of involuntary detachment of embossed sheets from the insulating panel as a whole, inconvenient installation, and inability to meet the requirements of the installation process, etc., to achieve superior heat insulation properties, less cost, and less thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

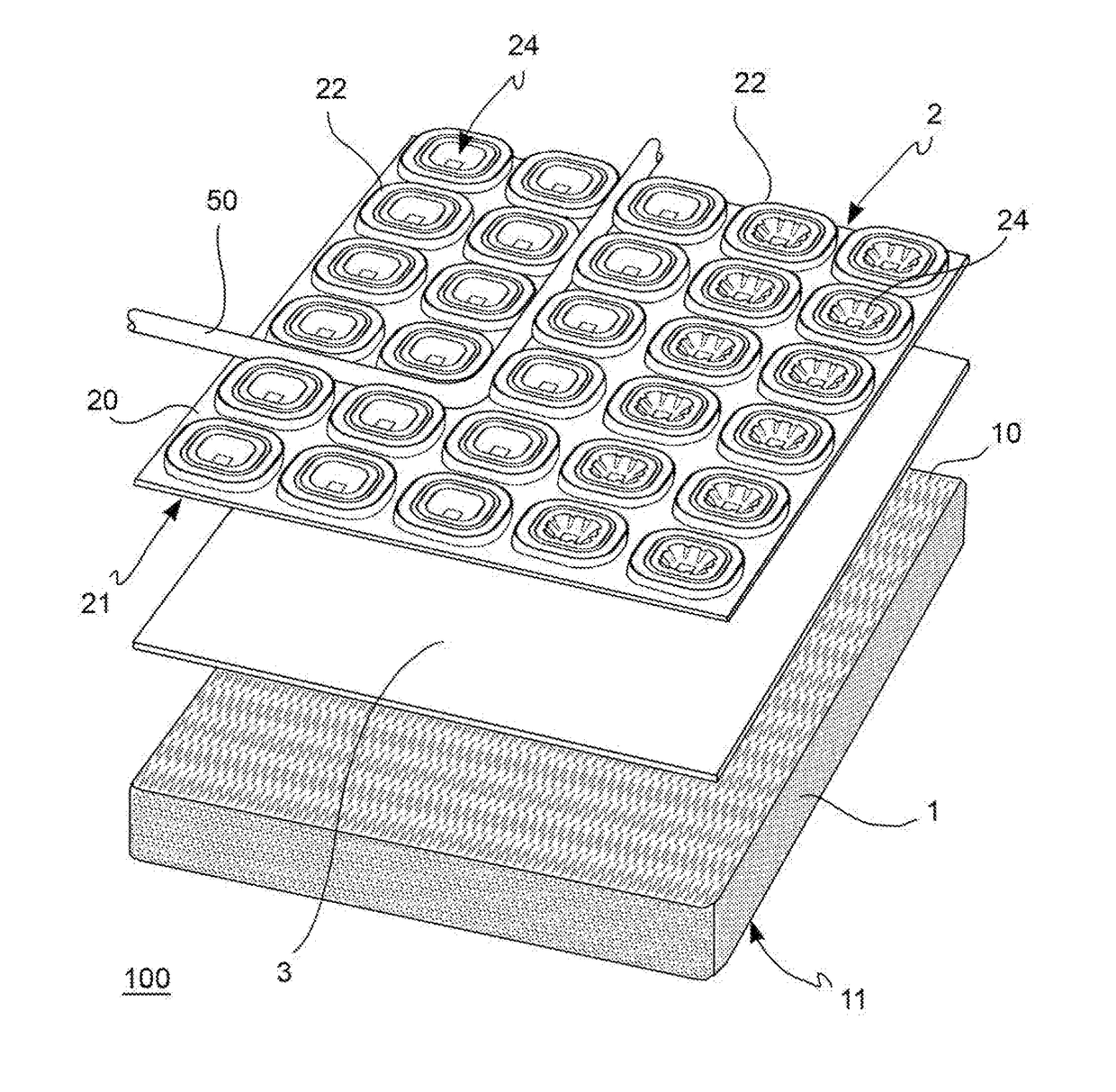

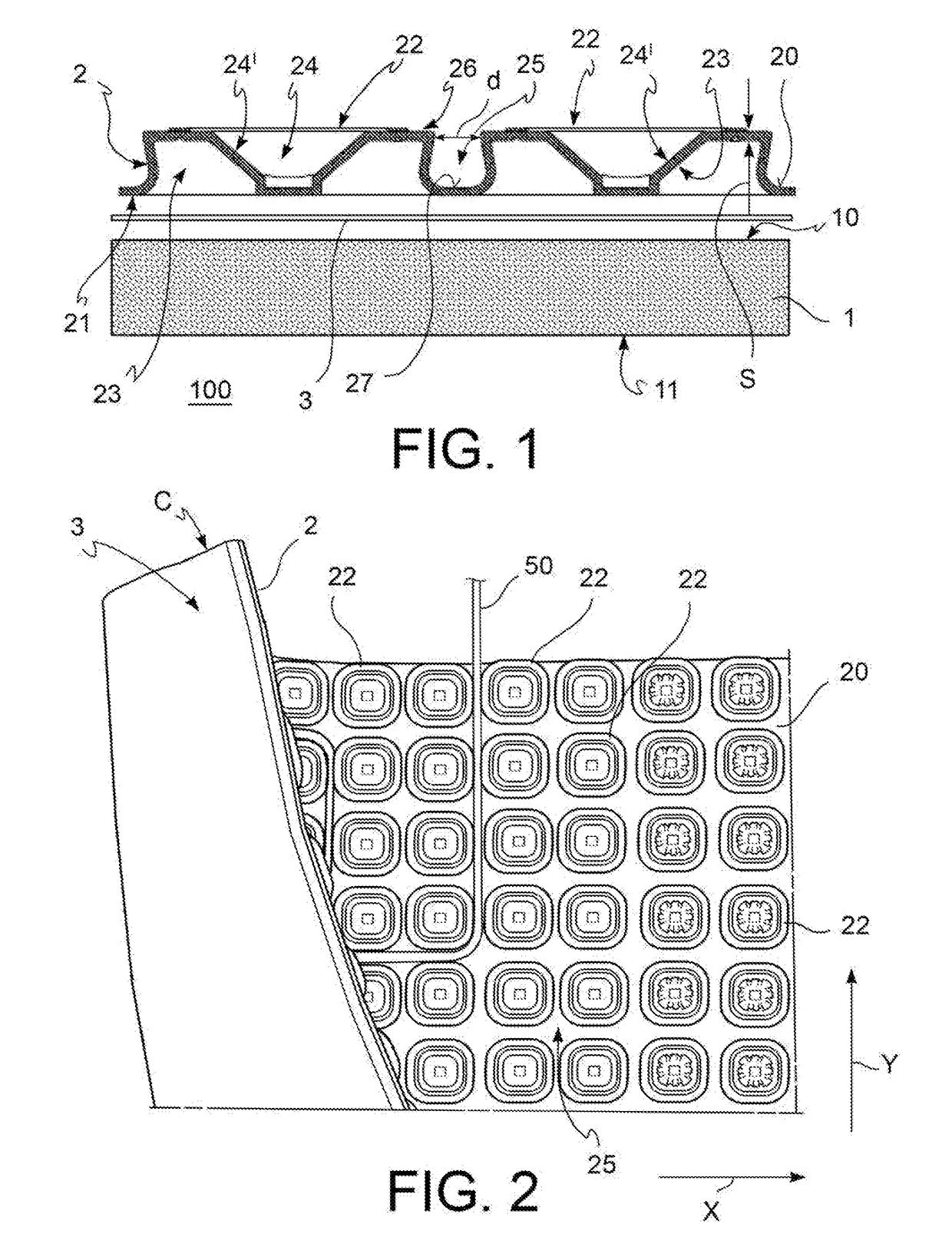

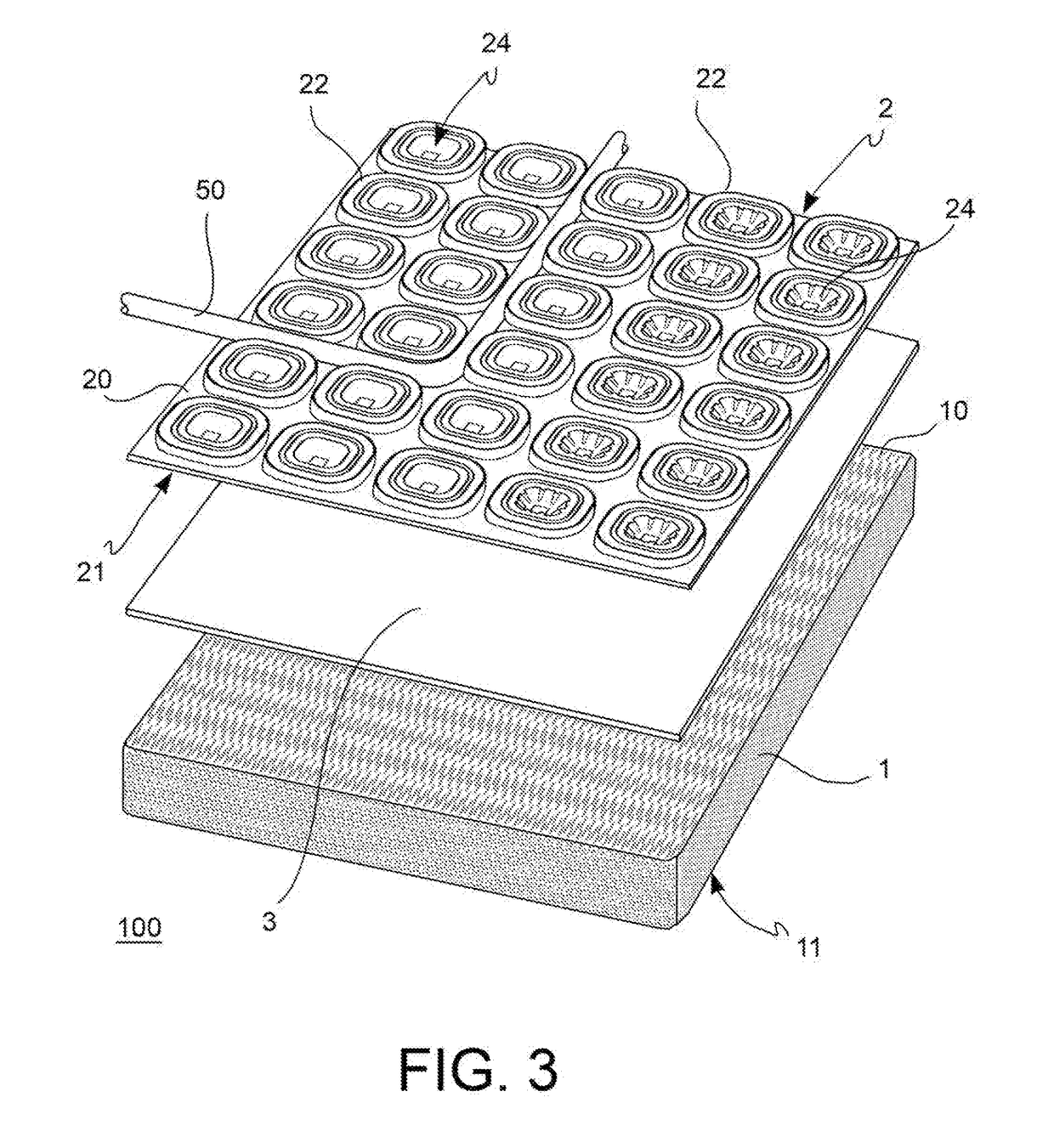

[0024]Referring to the aforesaid FIGS. 1 and 3, a multilayer insulating panel according to the invention for the installation of an electric heating system comprising electric heating wires 50 in subfloors or walls of a building is indicated as a whole with numeral 100.

[0025]In a floor heating system, such insulating panels 100 are placed on the slab of the room or living space of the building to be heated, thus being under the screed (or the glue) on which the tiles or other coverings of the usable floor are fixed. In a wall heating system, such insulating panels 100 are housed in cavities obtained in the walls, that is they are positioned on planes orthogonal to the plane of the slab in dry applications, associated for example with panels made of materials such as plasterboard or calcium silicate.

[0026]Hereinafter, the term insulating panel means a panel configured to insulate the living space thermally from the surrounding environments, in particular preventing the heat diffusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com