Forming method

a technology of shear forming and forming plate, which is applied in the field of shear forming plate, can solve the problems of substantial increase in the cost of the shear forming process, and achieve the effect of improving the fatigue properties of the shear formed pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

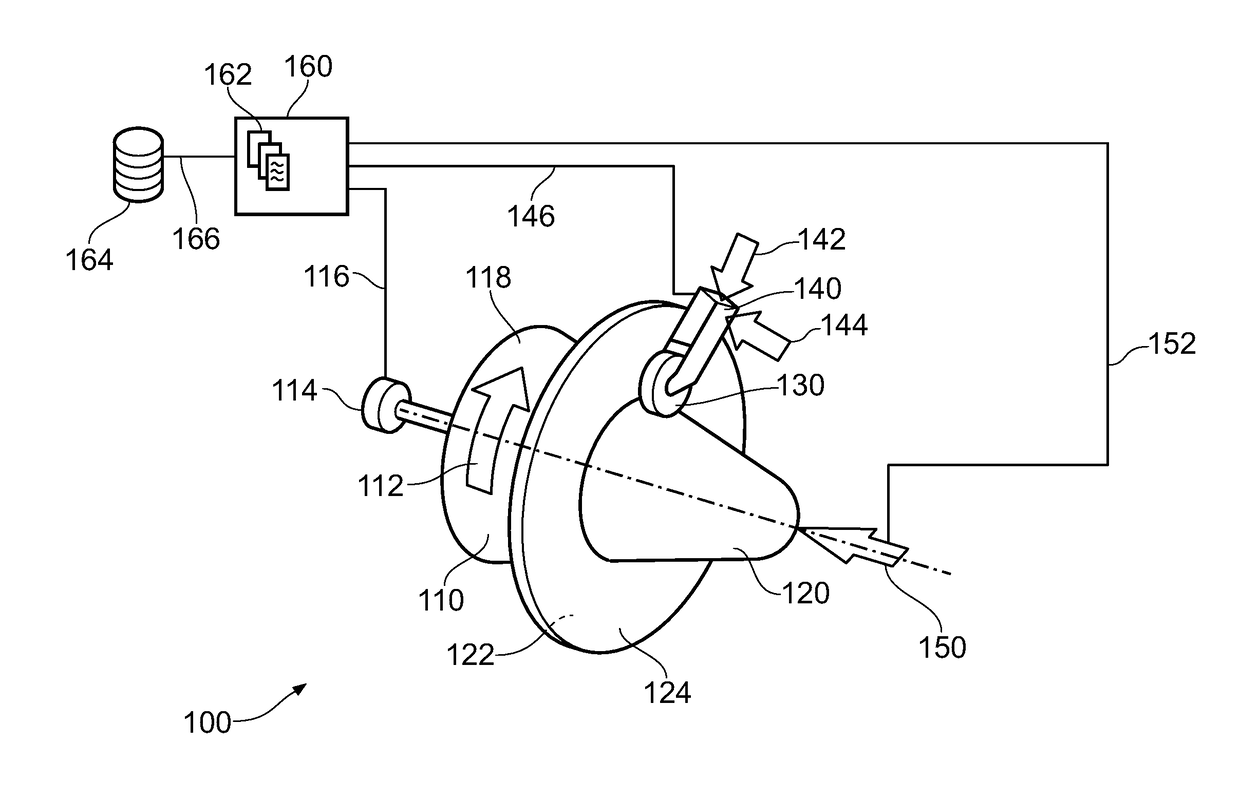

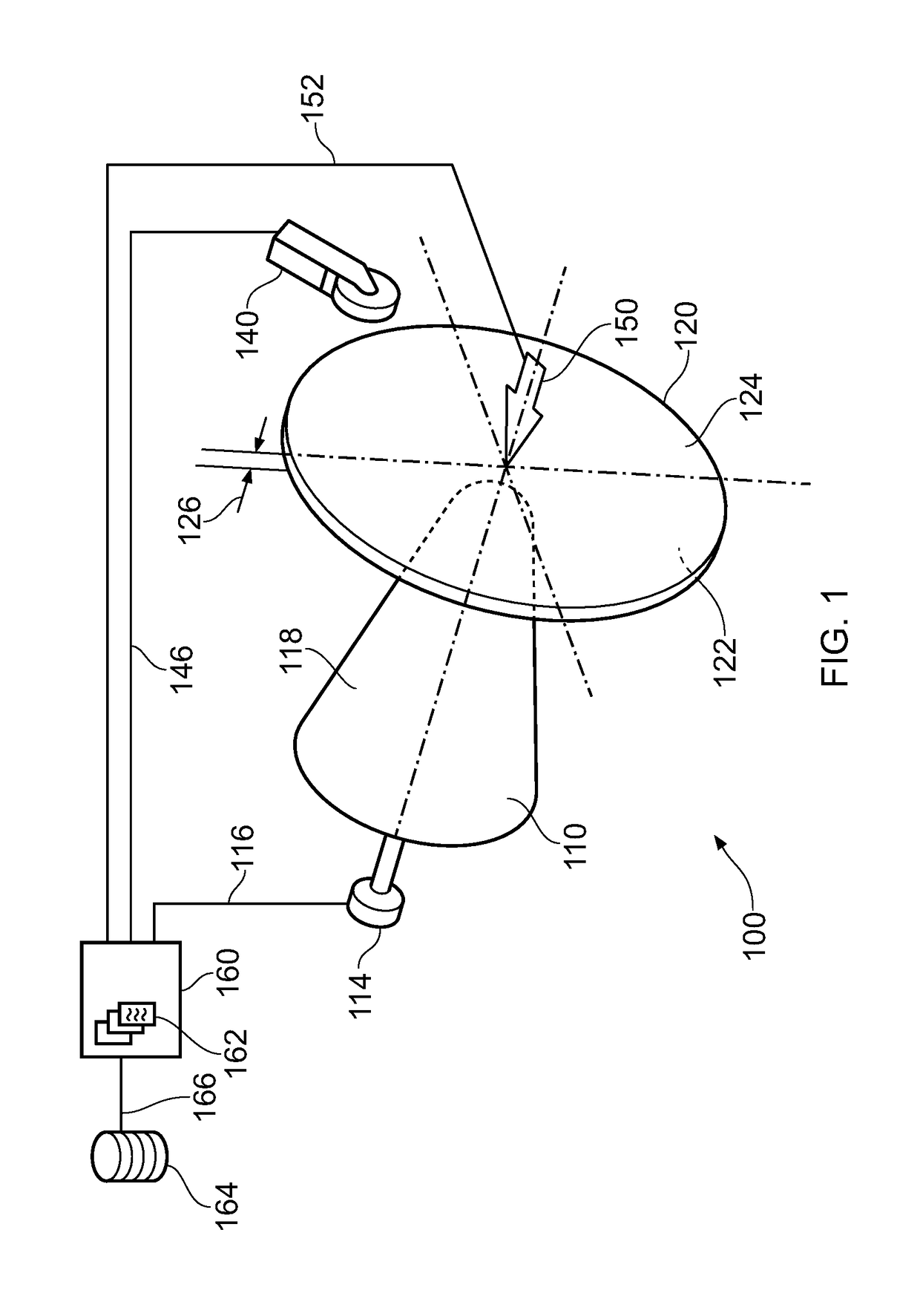

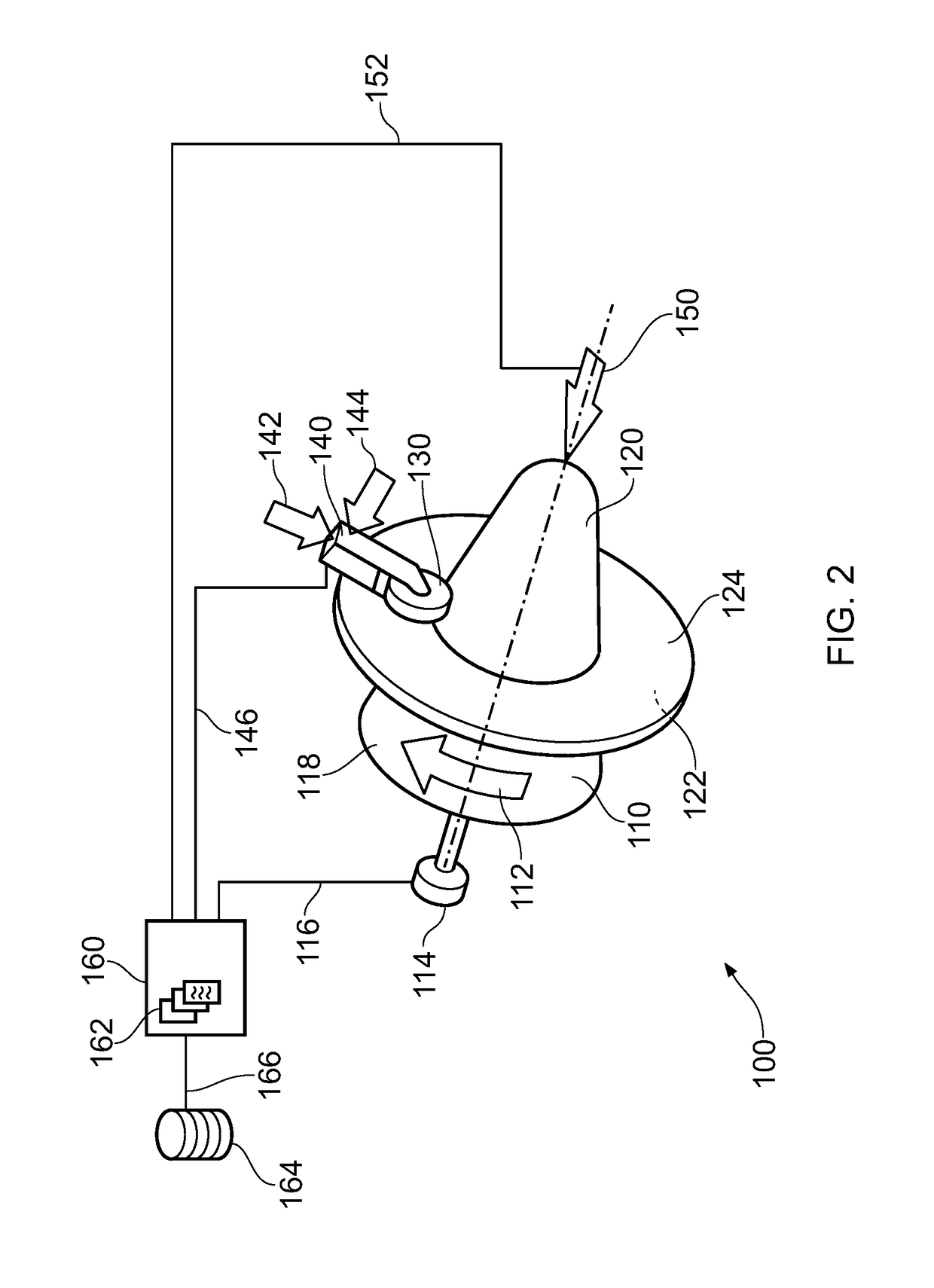

[0039]Referring to FIGS. 1 and 2, a shear forming apparatus that is capable of carrying out the method of the present disclosure is designated generally by the reference numeral 100.

[0040]The shear forming apparatus 100 comprises a mandrel 110 that can be rotated in a direction of rotation 112 by means of a rotary actuator 114. The mandrel 110 has a generally radially outwardly facing surface 118. This radially outwardly facing surface 118 is formed as an inverse of the desired surface profile of the finished article resulting from the shear forming process.

[0041]A pre-formed metallic sheet blank 120 is clamped against the distal end of the mandrel 110 by a clamping force 150. In this way the rotation 112 of the mandrel is transmitted to the sheet blank 120 that rotates co-operatively with the mandrel 110.

[0042]The sheet blank 120 is provided with a first surface 122 and an opposite second surface 124. In the present disclosure, the first surface 122 is subjected to a surface modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com