Methods, compositions and systems for enhancing the useful life of a transportation surface

a technology of transportation surface and composition, applied in the field of methods, compositions and systems for prolonging the life of transportation surfaces, can solve the problems of surface wear, surface quality decline, and loss of macrotexture with age, so as to enhance the useful life of a new transportation surface, facilitate the release and removal, and reduce frictional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043]

ComponentAmount (percentage, by weight)Lithium polysilicateabout 20%Alkali Metal Siliconate (sodiumabout 6% to about 15%methyl siliconate, potassiummethyl siliconate or potassiumpropyl siliconate)Silaneabout 2%WaterBalance

example 2

[0044]

ComponentAmount (percentage, by weight)Colloidal silicaabout 15%Alkali Methyl Siliconateabout 15%Silaneabout 2%WaterBalance

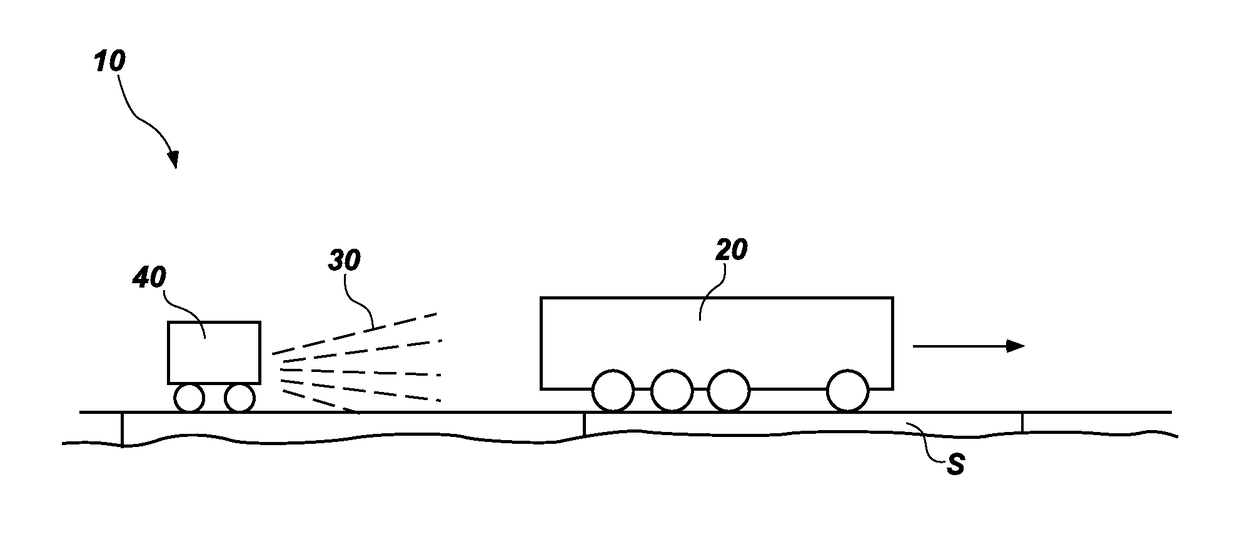

[0045]With returned reference to FIG. 1, various embodiments of protective compounds 30 that are within the scope of this disclosure and, optionally, various embodiments of systems 10 that are within the scope of this disclosure may be used in a variety of techniques for enhancing, or improving, the useful lives of transportation surfaces S.

[0046]A protective compound 30 and, optionally, a system 10 may be used to enhance, or improve, the useful life of a new transportation surface S, which may include new pavement, a new overlay, a topper (e.g., white top, blacktop, etc.) or the like. Processes that provide such enhancement may be carried out after an initial cure of transportation surface S, within thirty (30) days after placement of the transportation surface S, or at any other appropriate time. In some embodiments, the protective compound 30 may be app...

example 3

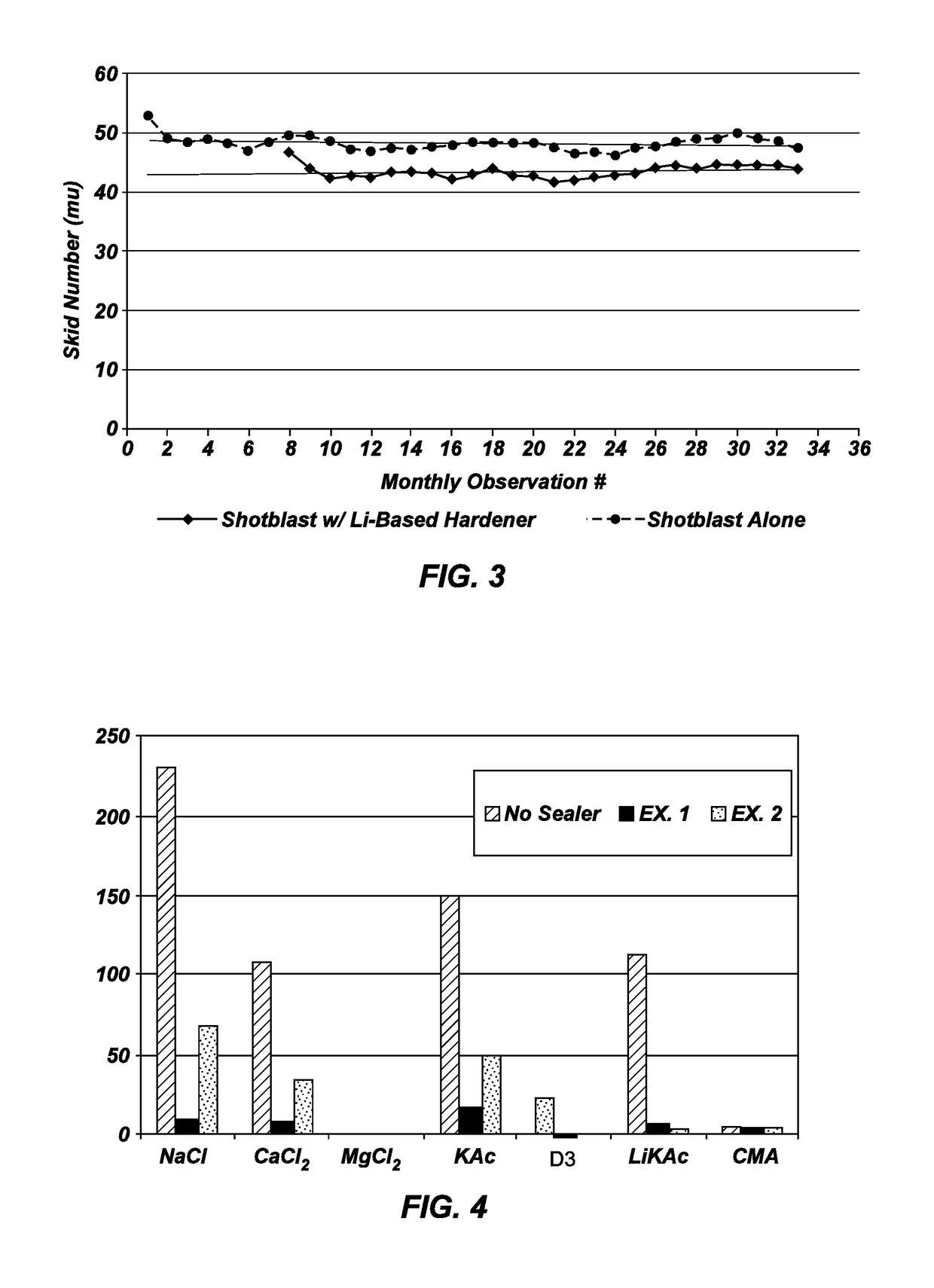

[0054]The California Department of Transportation (Caltrans) sponsored experimental research in which concrete pavement wear on a test section of U.S. Interstate Highway 80 (“I-80”) over Donner Pass was evaluated over a twelve (12) month period of time. It is well known that the Donner Pass section of I-80 experiences some of the harshest conditions in the United States in terms of snow-removal, tire chains and tire studs, and deicing salts. As expected, during the test and observation period, the test section was subjected to frequent snow plowing, traffic with snow chains and traffic with studded tires.

[0055]The test section included a three lane wide, one mile long section of I-80 at Donner Pass. It was divided into three subsections. Prior to treatment and testing, rut depths were measured at locations in each of the three subsections. A first of the three subsections served as a control; it was not subjected to physical alteration or chemically protected. A second of the three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com