Cosmetic composition for peel-off-type packs, and method for producing same

a peel-off type and cosmetic composition technology, applied in the field of cosmetic composition for peel-off type packs, can solve the problems of uneven skin tone, uneven skin tone, and uneven skin tone, and achieve the effects of accelerating drying, enhancing lifting effect, and enhancing skin ton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

Characteristics and Physical Properties of Examples and Comparative Examples 1 to 10

[0071]The cosmetic compositions for peel-off-type packs manufactured in the Examples were obtained by setting a mixing ratio so that gold pearl particles were stabilized, a drying speed was fast, and a feeling of use and characteristics of minimal irritation were secured. It was confirmed that the gold pearl particles stably floated even under a severe condition of 50° C. or more and were stable over a long period of time without agglomeration or separation in the formulation.

[0072]However, when the content of the first thickener (cellulose gum) was less than 0.1 parts by weight, as in Comparative Example 1, since the viscosity of the formulation was low, the cosmetic composition continuously flowed down during application on the skin, making it difficult to use.

[0073]When the first thickener was applied so that the content of the first thickener was more than 0.5 parts by weight, as in Comparative E...

experimental example 2

Skin Application Experiment

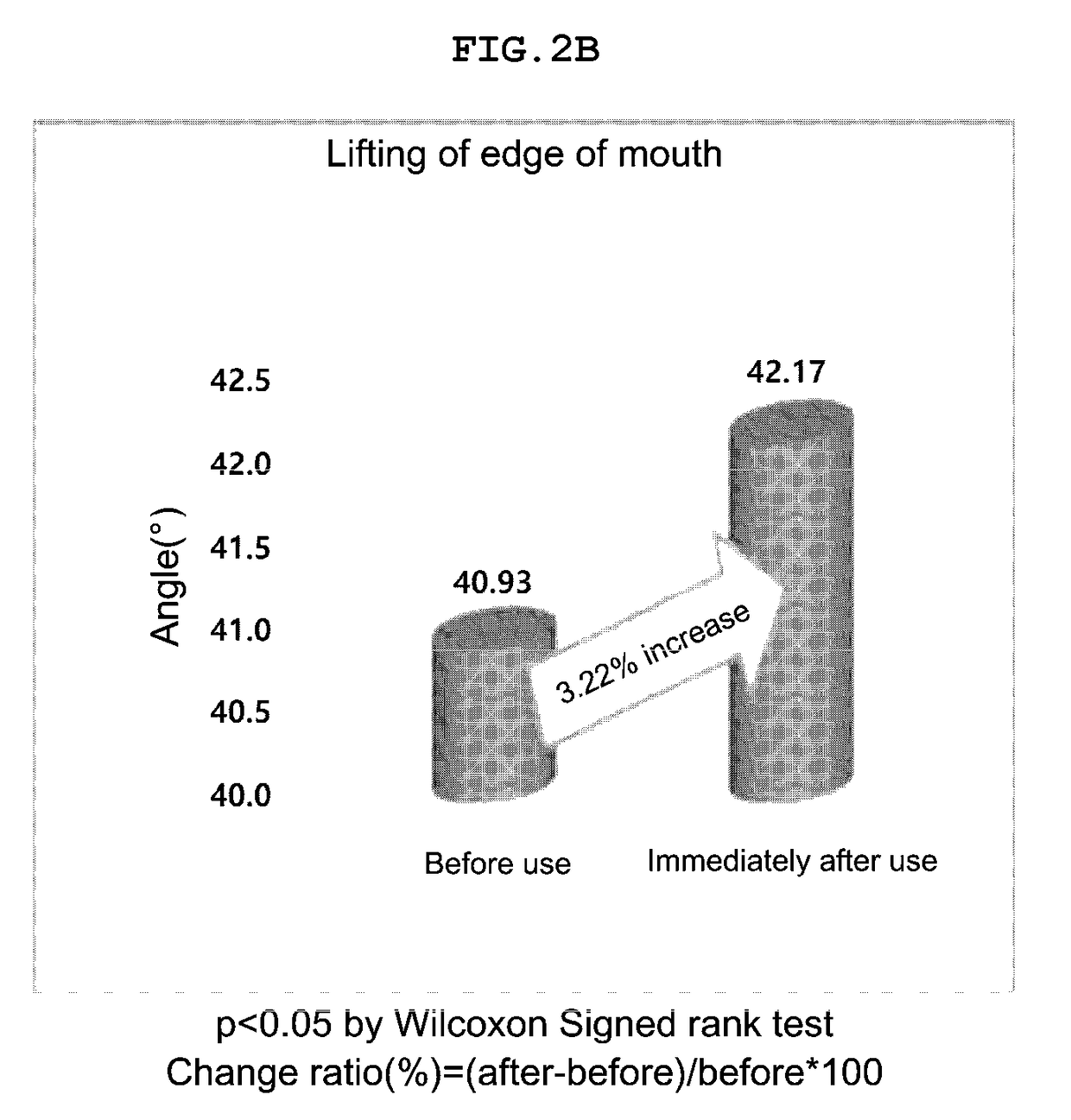

[0078]In order to confirm the lifting effect and the keratinous-waste-removal effect of the cosmetic compositions for peel-off-type packs manufactured in the Examples, 21 women of 20 to 59 years old were selected as subjects (mean age: 36.48 years). After cleansing, the cosmetic composition for peel-off-type packs manufactured in the Example was abundantly spread on the skin of each subject. When the cosmetic composition was completely dried after 20 to 30 minutes, the dried film was peeled off. The above-described procedure was repeated once a day for 7 days. Before use, immediately after one use, and 7 days after use, the keratin removal effect and the skin elasticity change at the edge of the eye and at the edge of the mouth of each subject were observed.

[0079]With respect thereto, the state of the composition was photographed at the time of application and until a peeling-off process 15 minutes after application, and is shown in FIG. 1.

[0080]As shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com