Autonomous Submersible Offshore Marine Platform

a technology of autonomous submerged marine platform and autonomous submerged platform, which is applied in the direction of underwater equipment, special-purpose vessels, vessel construction, etc., can solve the problems of loss of military or commercial mission capability and availability, large and expensive surface offshore marine platform, and large crew and capability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

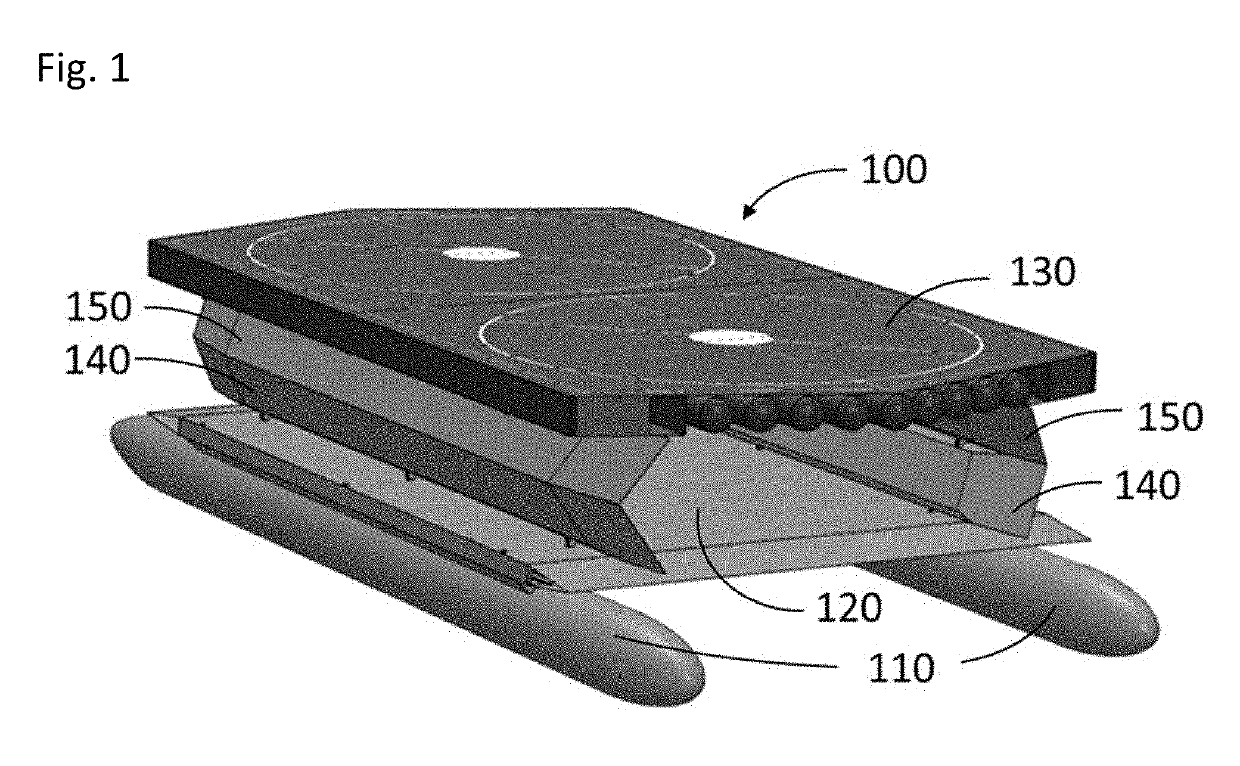

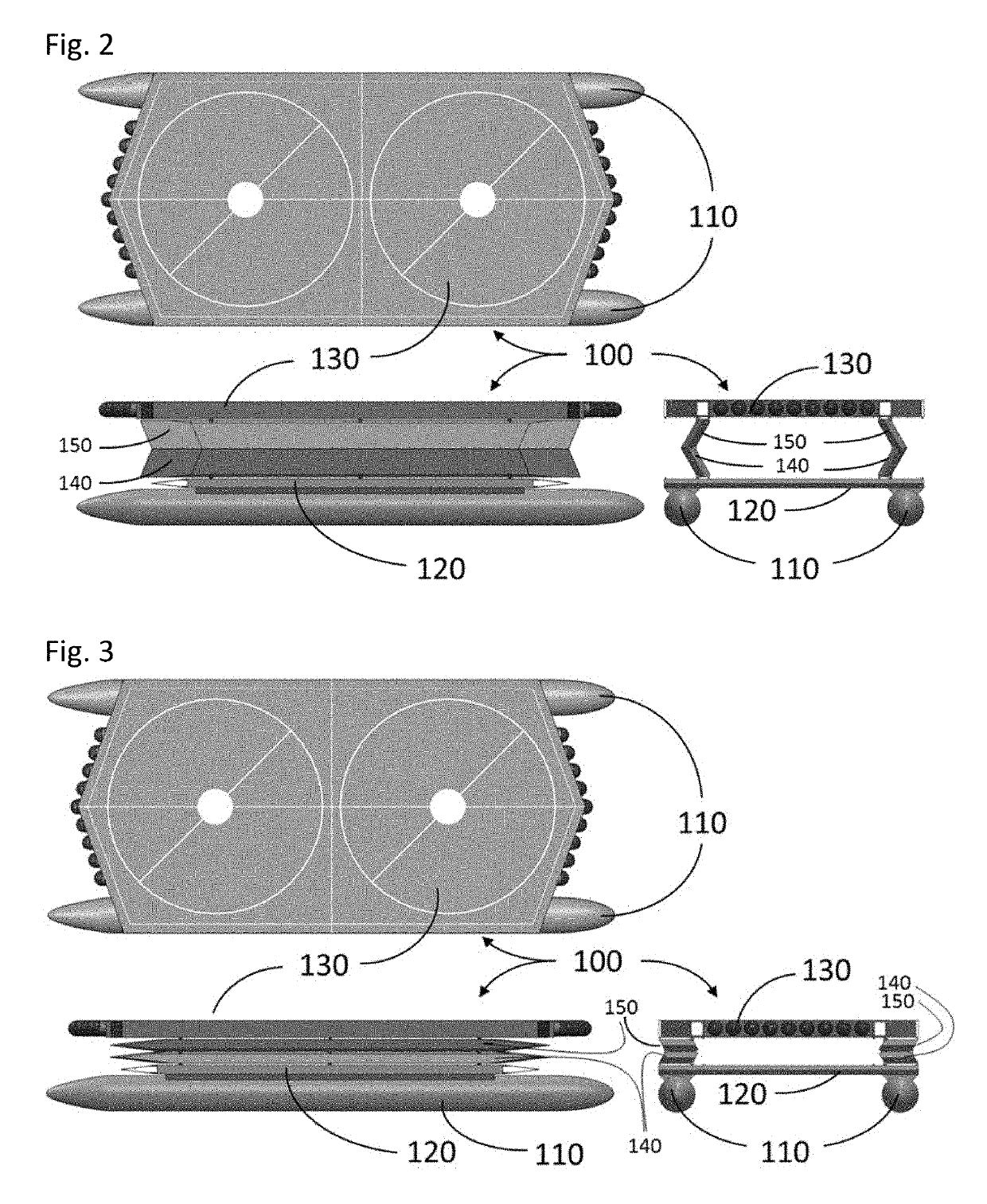

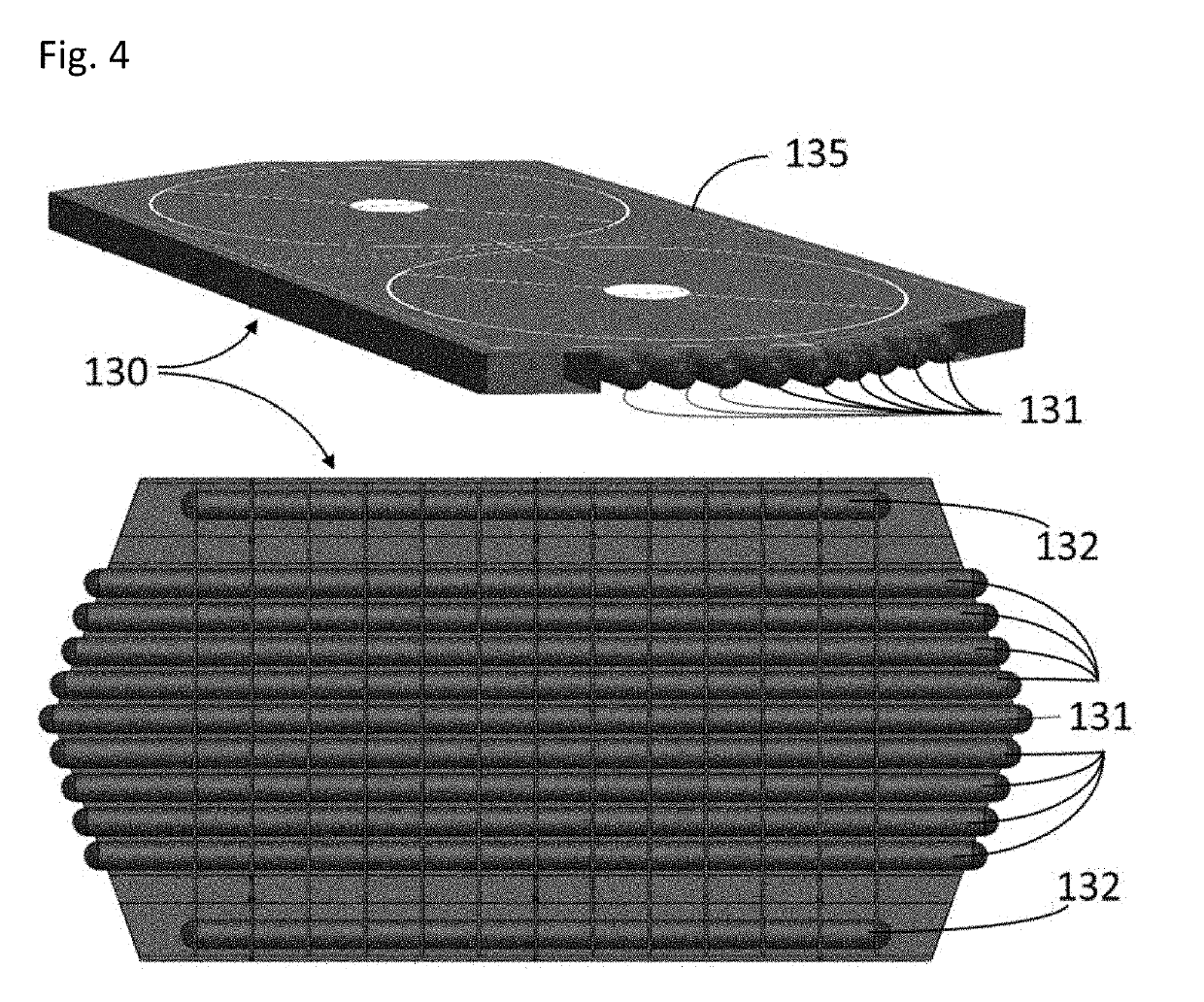

[0053]Referring now to the drawings in detail, Page 1 FIG. 1 illustrates an example of an Autonomous fully-Submersible Offshore Marine Platform (referred to as the ASOMP) 100, constructed in accordance with the present invention that operates as both a surface platform and submersible, with the ability to hibernate for extended periods of time on the seafloor. The ASOMP 100 is comprised of 4 major portions:[0054]a. A Lower Hull 110 portion with at least two submerged pod shaped Lower Hulls 110 that provide a substantial portion of the ASOMP's buoyancy. Said Lower Hulls 110 are of pressure vessel form able to withstand submergence hydrostatic pressures. Tanks within said Lower Hulls provide a ballast capacity sufficient to submerge and surface the ASOMP.[0055]b. A Cross Structure portion 120 connecting said Lower Hulls. Said Cross Structure 120 is a primary structural member providing a structural arrangement that significantly reduces hydrodynamic load created stresses of convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com