Synthetic rubber tile with thermal resistance modulation

a technology of synthetic rubber and modulation, applied in the direction of sustainable buildings, papermaking, transportation and packaging, etc., can solve the problems of hardness, lower impact resistance, and asphalt tile texture, and achieve the effects of reducing heat flow, high thermal conductivity, and reducing heat flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

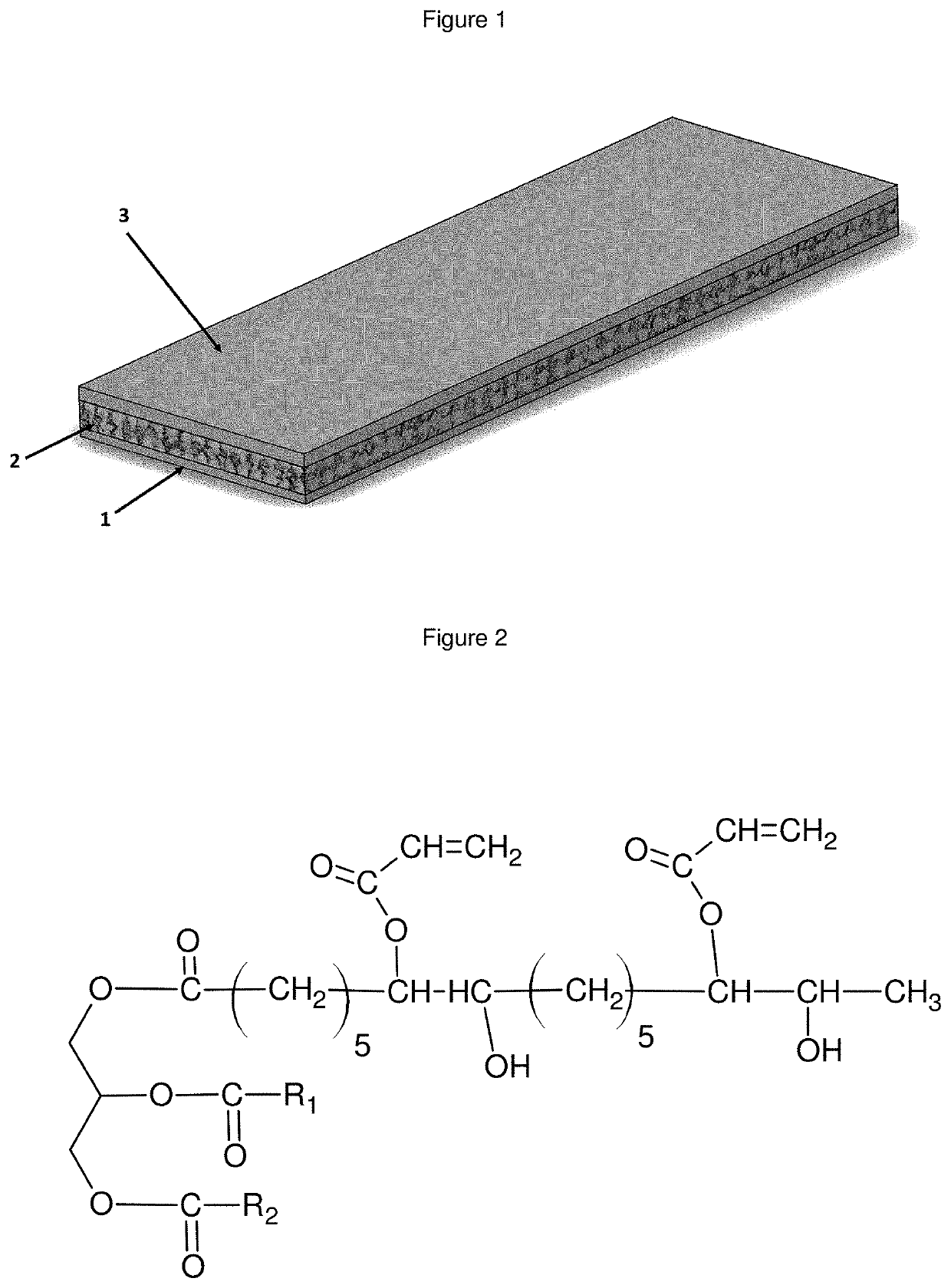

Image

Examples

example 1

[0020]Integrate synthetic rubber with an average particle size of 2.5 mm, polyunsaturated macromonomer of GAEA, styrene and Benzoyl peroxide in a batten mixer with the amounts described in Table 1, and mix at a speed of 40 to 100 rpm for a period of 15 minutes, until achieving the complete integration of the components in a homogeneous paste.

[0021]Feed the paste produced to a dosing unit of an endless screw connected to a pultrusion dice set at an inside temperature of 180° C. The pultrusion dice is also fed with kraft paper of 91.5 cm wide and 200 g / m2 by the lower part of the dice; this paper serves as a transport element of the paste.

[0022]Pull the kraft paper through a traction roller while the paste is fed simultaneously to the pultrusion dice set at 180° C. at a speed that allows the mixture to have a residence time in the pultrusion roller for at least 40 seconds.

[0023]Introduce it into an exit of the pultrusion dice, the composite of synthetic rubber obtained in a continuous...

example 2

[0024]Integrate the synthetic rubber with an average particle size of 2.5 mm, polyunsaturated macromonomer of GAEA, butyl acrylate and Benzoyl peroxide in a batten mixer with the amounts described in Table 2, and mix at a speed of 40 to 100 rpm for a period of 15 minutes, until achieving the complete integration of the components in a homogeneous paste.

[0025]Feed the paste produced to a dosing unit of an endless screw connected to a pultrusion dice set at a temperature of 180° C. inside. The pultrusion dice is also fed with bond paper of 91.5 cm wide and 200 g / m2 for the lower part of the dice; this paper serves as a transport element for the paste.

[0026]Pull the bond paper using a traction roller while the resin is fed simultaneously to the pultrusion dice set at 180° C. at a speed that allows the mixture to have a residence time at the pultrusion roller of 30 seconds as a minimum.

[0027]Introduce at the exit of the pultrusion dice, the composite of synthetic rubber obtained in a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com