System and method for cryogenic air separation using a booster loaded liquid turbine for expansion of a liquid air stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

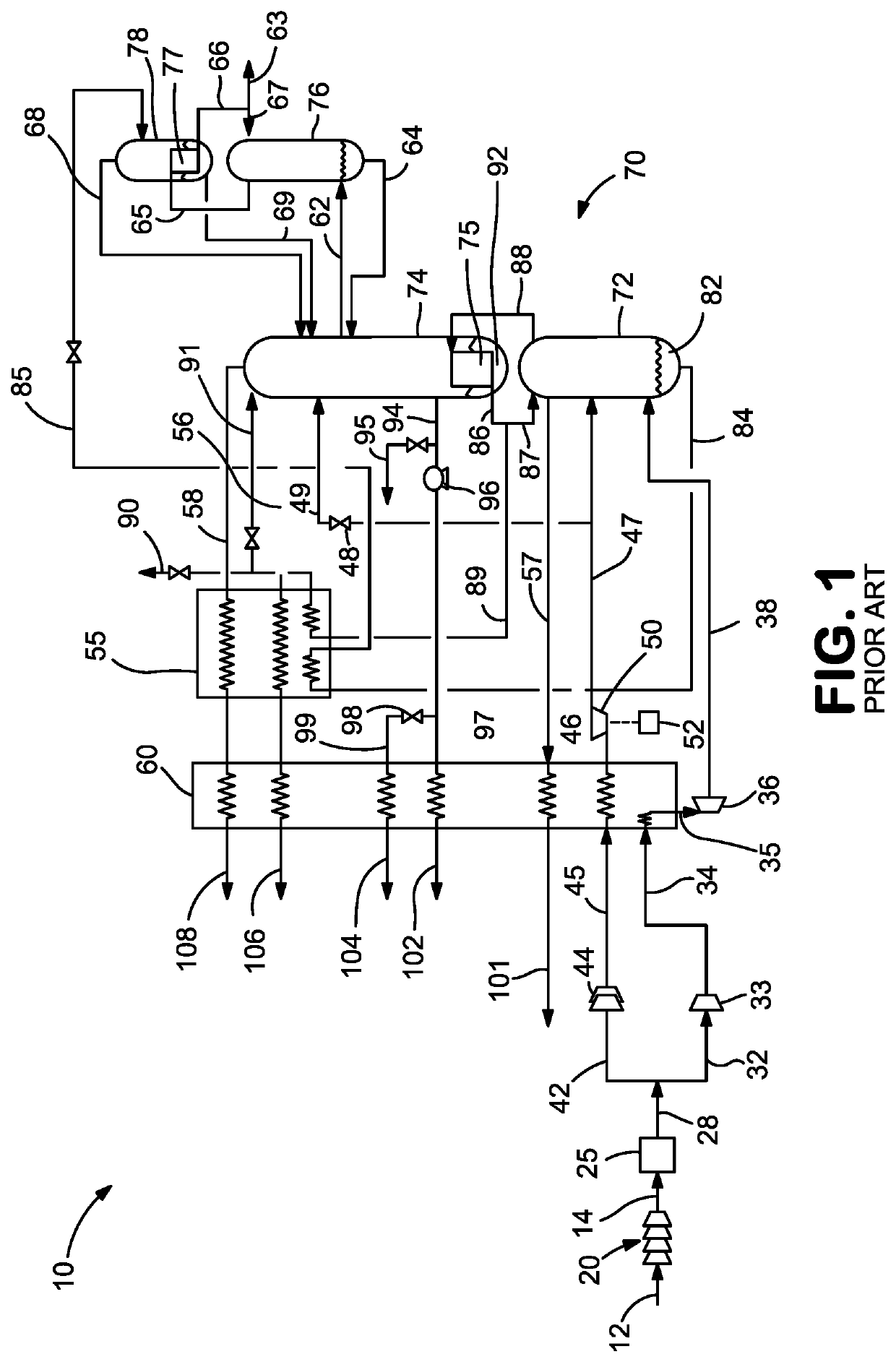

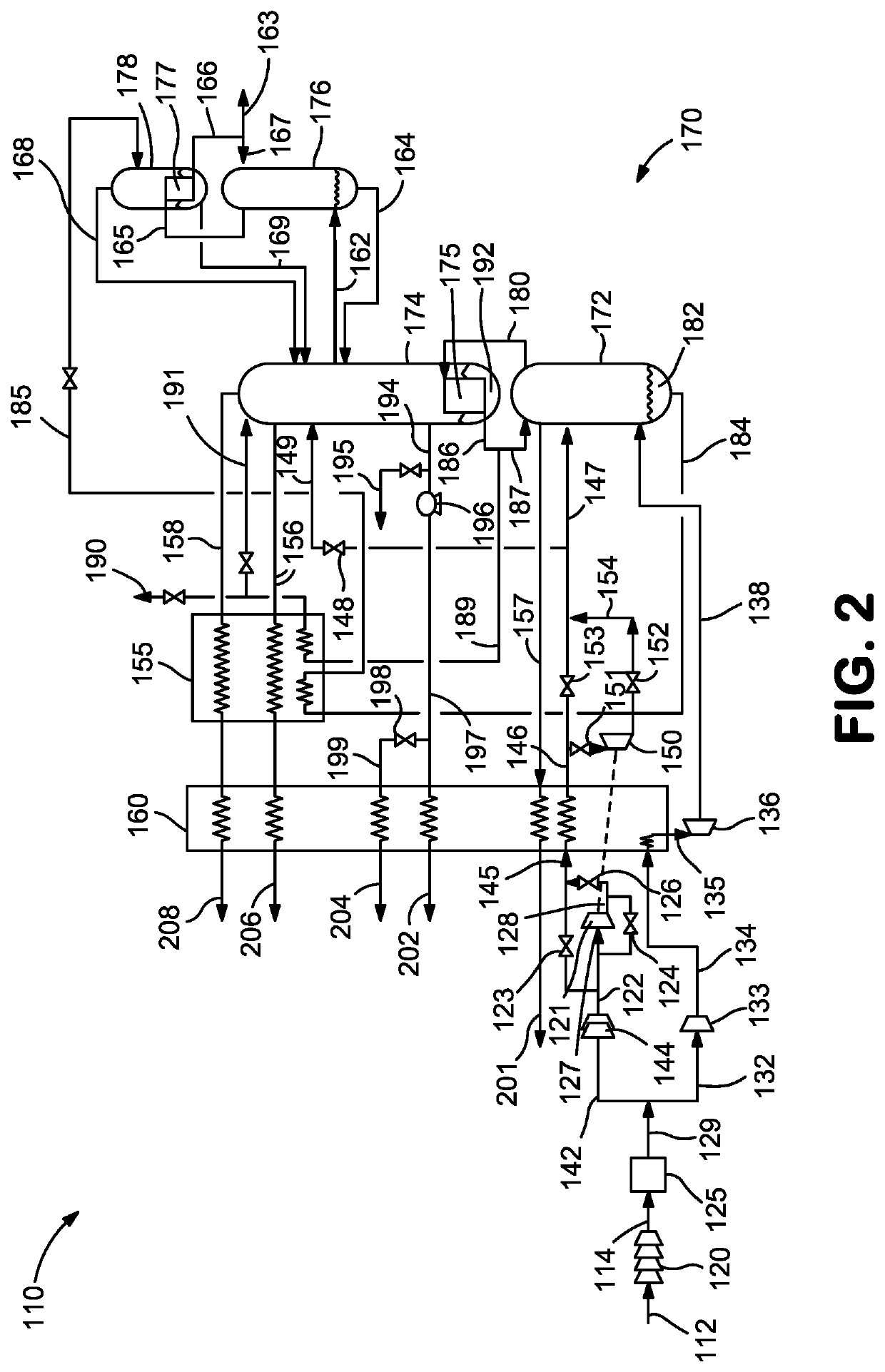

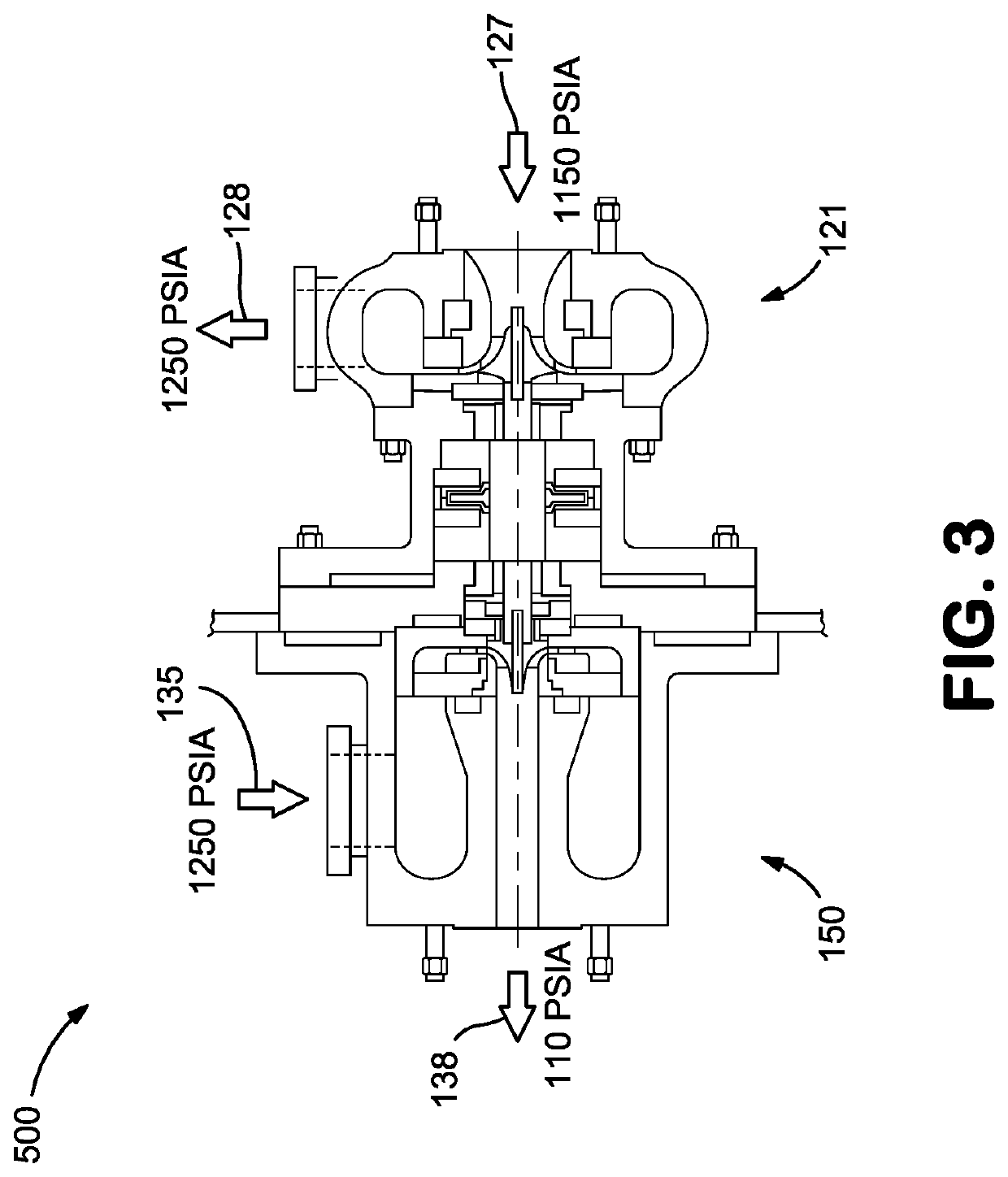

[0017]With reference to FIG. 1, a prior art cryogenic air separation unit 10 employing a generator loaded liquid turbine 50 is illustrated. FIG. 2 and FIG. 4, on the other hand, illustrate embodiments of a cryogenic air separation unit 110, 210 employing a booster-loaded loaded liquid turbine 150, 250.

[0018]As many of the components and streams in the prior art cryogenic air separation unit having a generator loaded liquid turbine 50 are the same or similar to the present cryogenic air separation unit 110, 210 employing the booster-loaded loaded liquid turbines 150, 250, much of the following description is applicable to each of FIG. 1, FIG. 2, and FIG. 4 and the reference numerals identifying the similar components are the same in each of the drawings. The differences between the prior art cryogenic air separation unit of FIG. 1 having a generator loaded liquid turbine and the those of FIGS. 2 and 4 having booster-loaded loaded liquid turbines, will be highlighted, as appropriate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com