Electrode Manufacturing Method Comprising Cleaning Step Using Laser, Electrode Manufactured By Method, and Secondary Battery Comprising Same

a manufacturing method and electrode technology, applied in the direction of sustainable manufacturing/processing, battery components, battery cells, etc., can solve the problems of reducing the capacity of the electrode, deteriorating the performance of the battery cell, and reducing the safety of the secondary battery, so as to achieve a significant reduction of the sliding generation level in the boundary region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

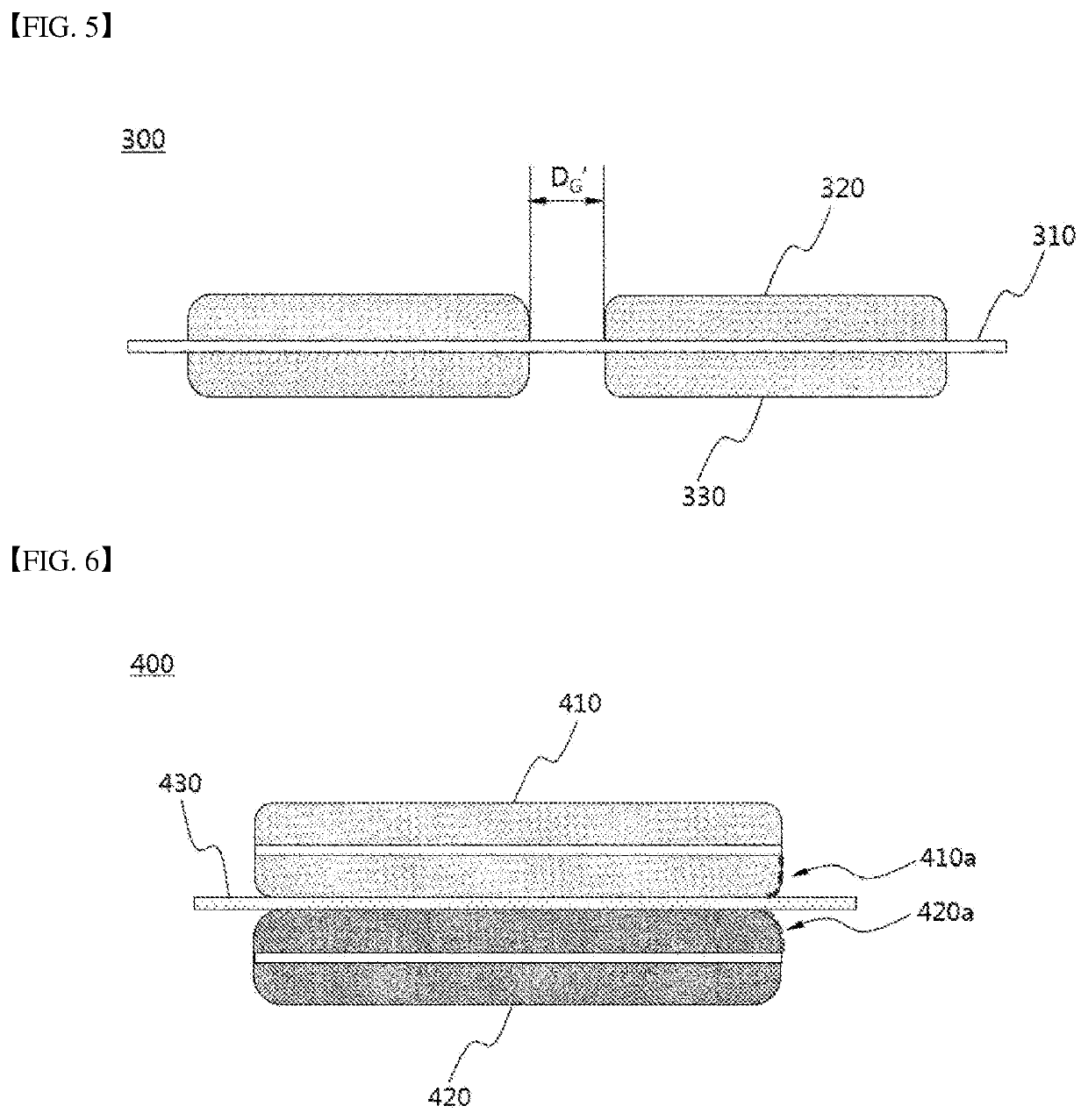

[0054]FIG. 3 is a schematic diagram illustrating an electrode manufacturing process according to an embodiment of the present invention. Referring to FIG. 3, an electrode according to the present invention has a structure in which a top-coated electrode mixture layer 120 and a back-coated electrode mixture layer 130 are formed on opposite surfaces of a current collector 110. In the present invention, the electrode is manufactured through a step 100 of cleaning the end of the coated part through laser irradiations 141 and 142 along the boundary line of the coated part contacting the non-coated part. Generation of a sliding phenomenon at the end of the electrode mixture layers 120 and 130 is prevented through the laser irradiations 141 and 142.

[0055]FIG. 4 is a cross-sectional view illustrating an electrode manufacturing process according to an embodiment of the present invention. Referring to FIG. 4, the cleaning step 200 of the present invention is performed so that lines irradiatin...

second embodiment

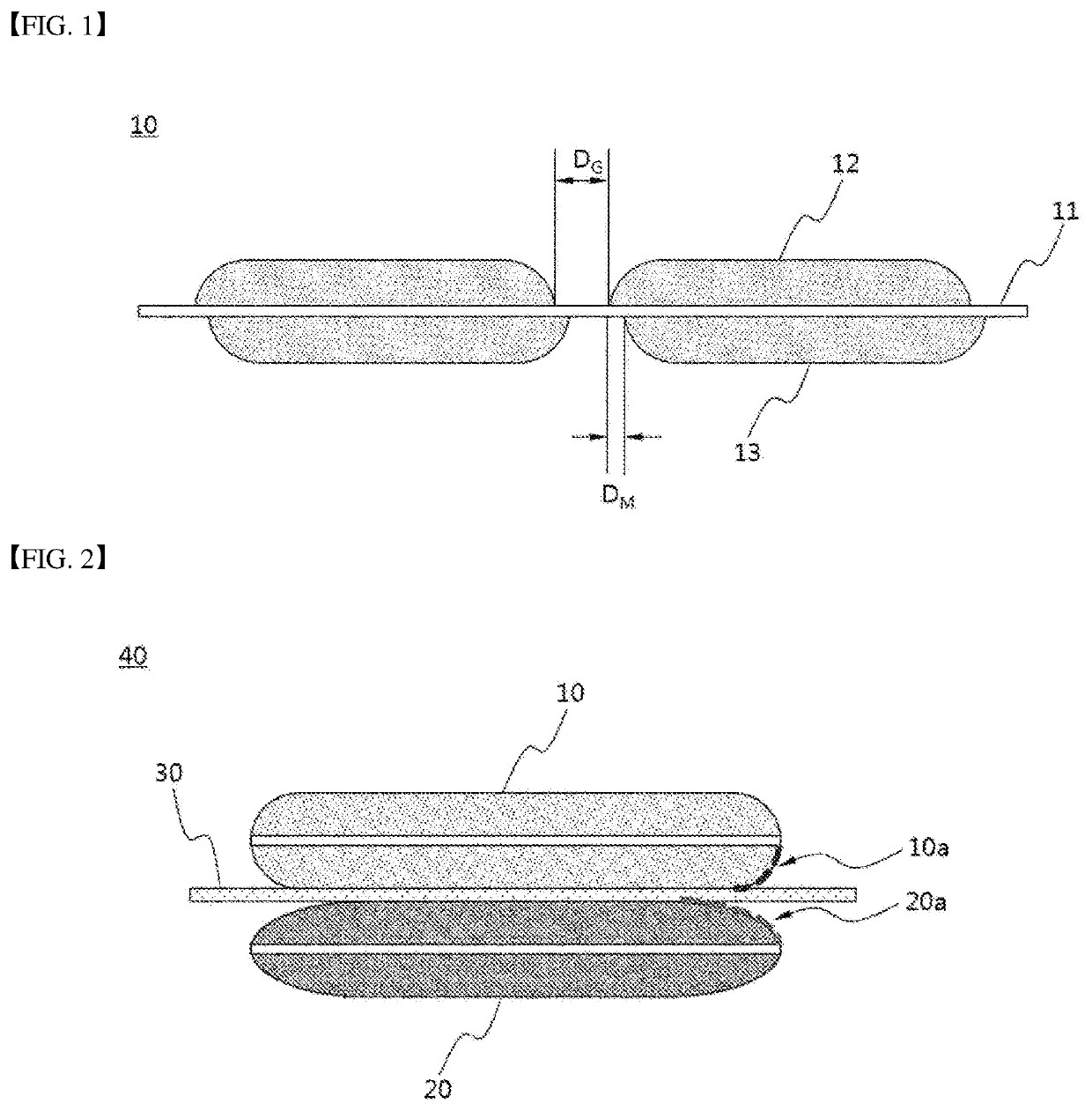

[0056]FIG. 5 is a cross-sectional view illustrating a structure of an electrode according to an embodiment of the present invention. Referring to FIG. 5, a first electrode 300 has a structure in which a top-coated electrode mixture layer 320 and a back-coated electrode mixture layer 330 are formed on opposite surfaces of a current collector 310. Further, each of the electrode mixture layers 320 and 330 includes a coated part, on which an electrode mixture layer has been applied, and a non-coated part. A separation distance between coated parts having the electrode mixture layer formed thereon means a width (DG′) of the non-coated part. In the present invention, in the cleaning step through laser irradiation, lines irradiating laser to the top-coated electrode mixture layer 320 and the back-coated electrode mixture layer 330 of the electrode current collector 310 correspond to each other in a direction that is perpendicular to the electrode current collector 310. Hence, a mismatch re...

third embodiment

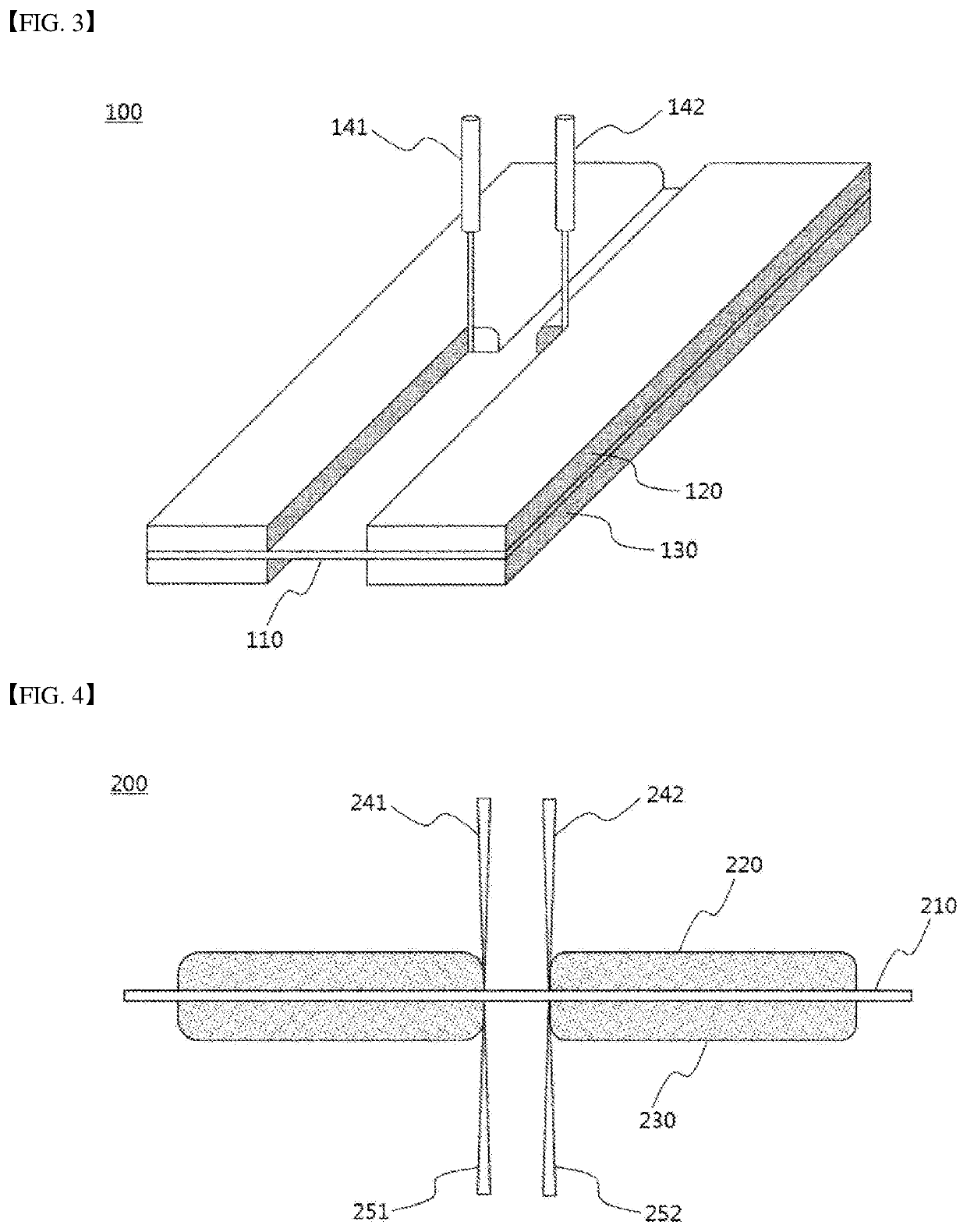

[0057]FIG. 6 is a cross-sectional view illustrating a laminated structure of an electrode assembly prepared according to an embodiment of the present invention. Referring to FIG. 6, the electrode assembly 400 has a structure in which the first electrode 410 and the second electrode 420 are formed on opposite surfaces on the basis of the separator 430. Different sliding levels 410a and 420a are generally shown in the boundary region of the electrode mixture layer in each process of manufacturing the first and second electrodes 410 and 420. However, in the present invention, the electrode mixture layer of the first and second electrodes 410 and 420 shows the same or similar sliding levels 410a and 420a in the boundary region through the cleaning step by laser irradiation. As such, the loading ratio of the positive electrode mixture layer corresponding to the negative electrode mixture layer is maintained equally even in the boundary region of the electrode mixture layer.

[0058]The abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| formation angle | aaaaa | aaaaa |

| formation angle | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com