Non-contact IC card and IC card communication system

a communication system and non-contact technology, applied in the field of non-contact ic cards, can solve the problems of difficult to maintain a high mechanical strength of such a card, the inability to control the distance between the substrate and the ic chip using the au bump, etc., and achieve the effect of maintaining communication characteristics, enhancing the connection reliability of the mounting portion of the ic chip, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Referring now to the accompanying drawings, the preferred embodiments of the present invention will be described below.

First, referring to FIGS. 1, 2, 7 and 8, the first preferred embodiment of the present invention will be described.

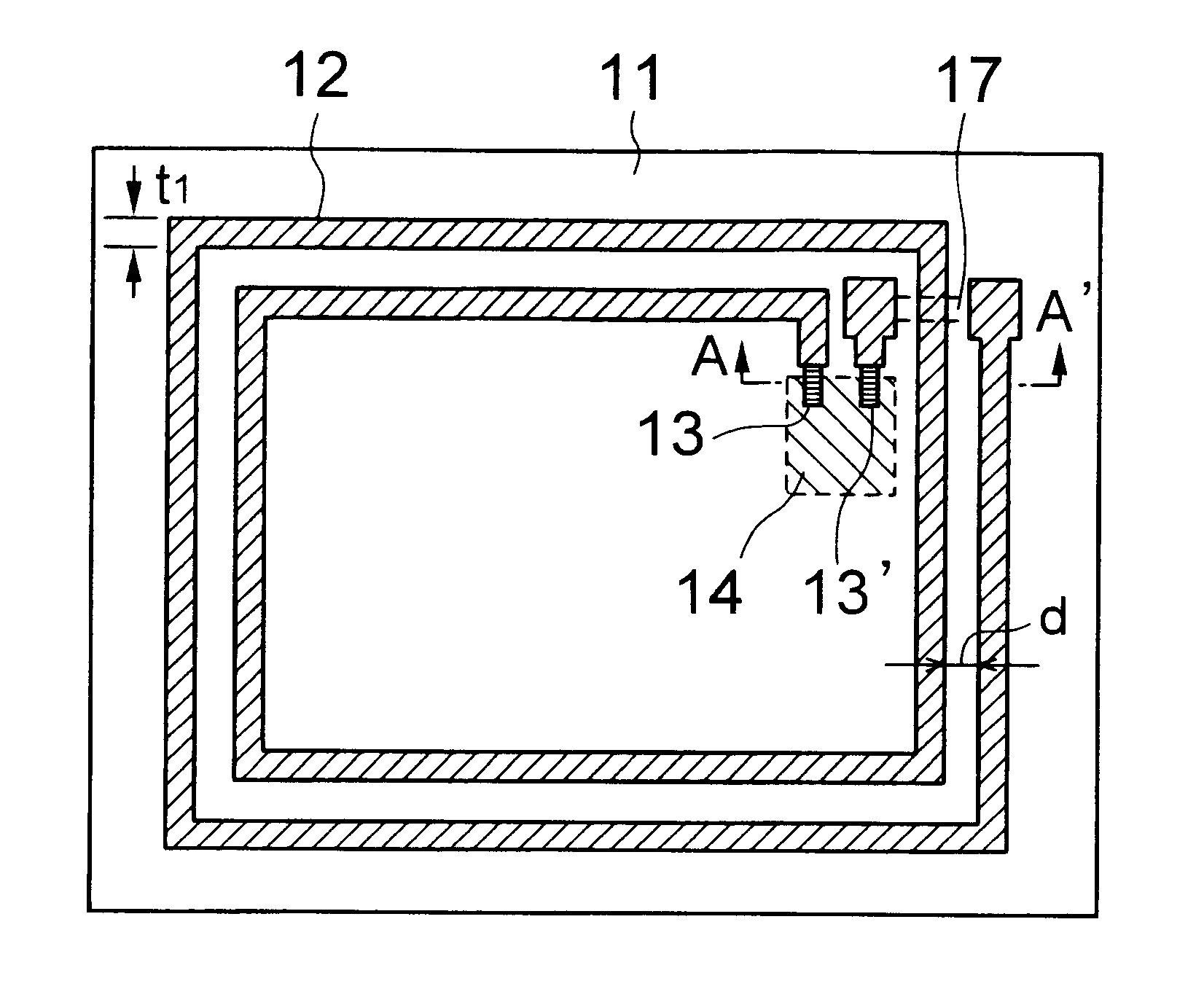

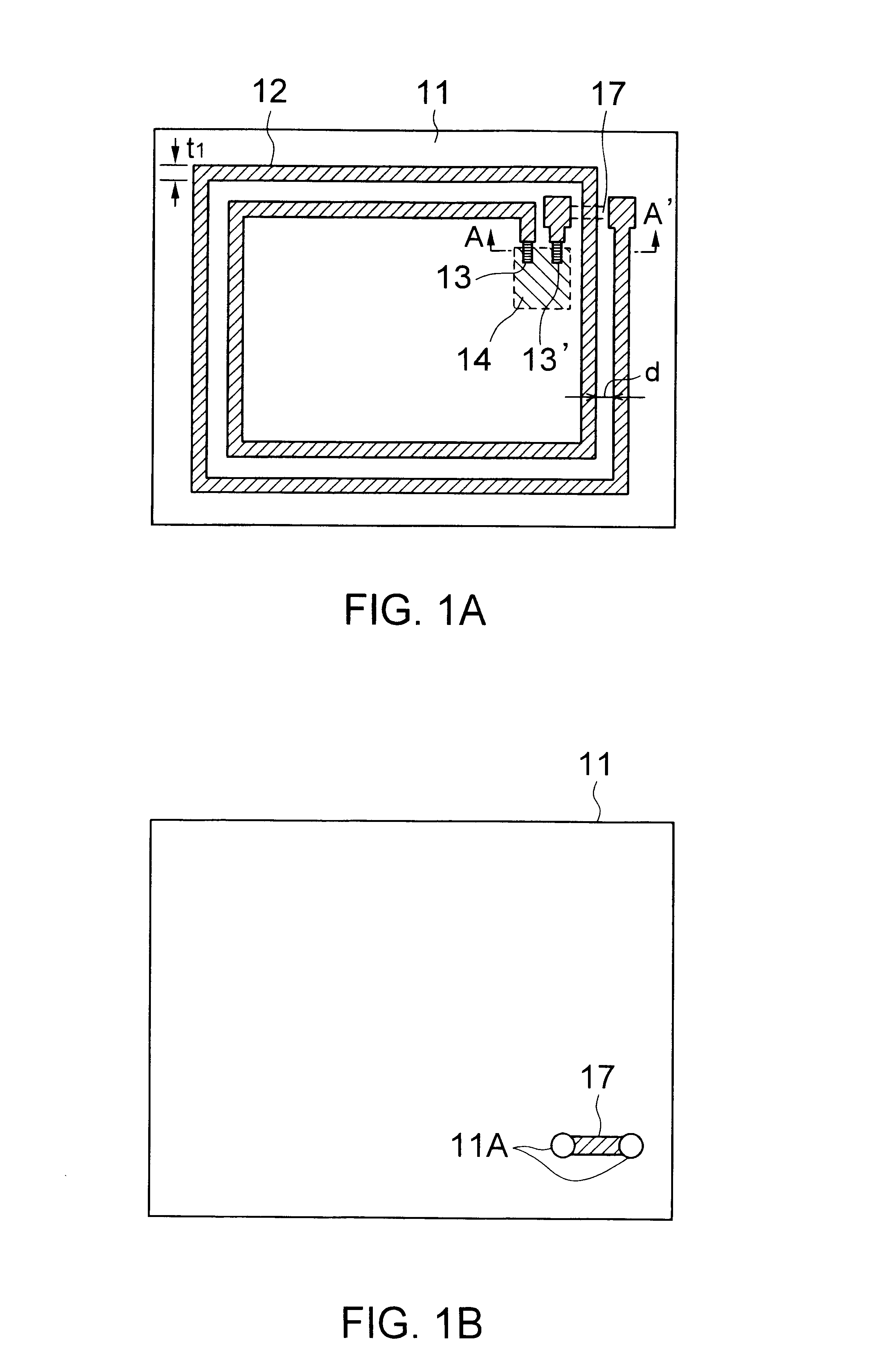

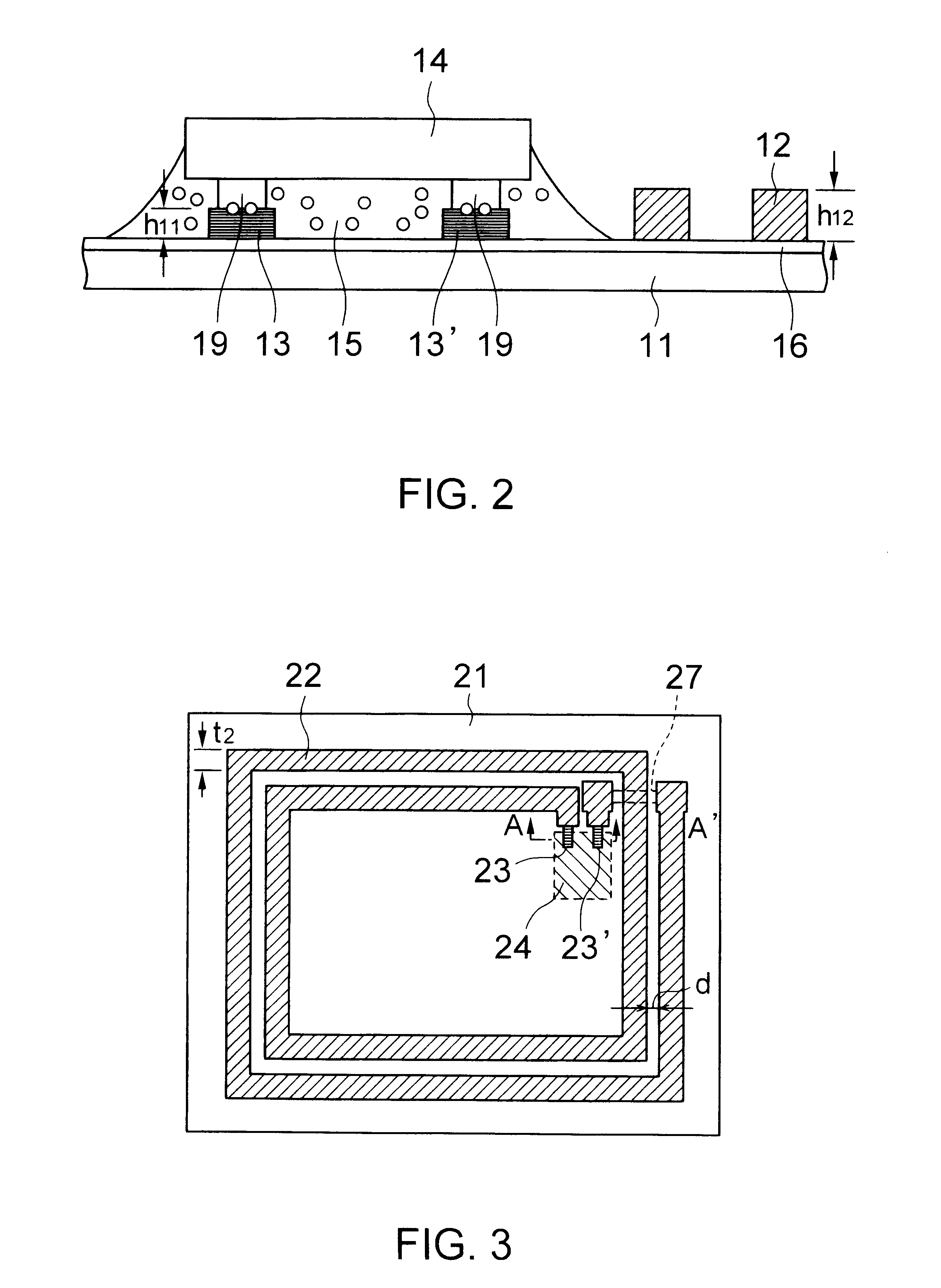

FIG. 1 is a plan view of a non-contact IC card according to the present invention, and FIG. 2 is a sectional view of an 20 IC chip mounting portion of a non-contact IC card according to the present invention (a sectional view taken along line A-A' of FIG. 1). FIG. 7 is a characteristic diagram showing the relationship between the antenna resistance of an antenna coil of FIG. 1 and a communication distance, and FIG. 8 is a schematic perspective view of an IC card communication system. The non-contact IC card comprises: an insulating substrate 11 of an insulating material, such as an epoxy resin or a polyimide resin; an antenna coil 12 of a conductor, such as aluminum or copper; IC chip connecting terminals 13 and 13' which constitute a part of the antenn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com