Loudspeakers

a loudspeaker and wave panel technology, applied in the direction of transducer diaphragms, electromechanical transducers, diaphragm construction, etc., can solve the problems of only ever increasing the diameter slightly, premature roll-off, and power handling and excursion problems, and achieve the effect of improving off-axis power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

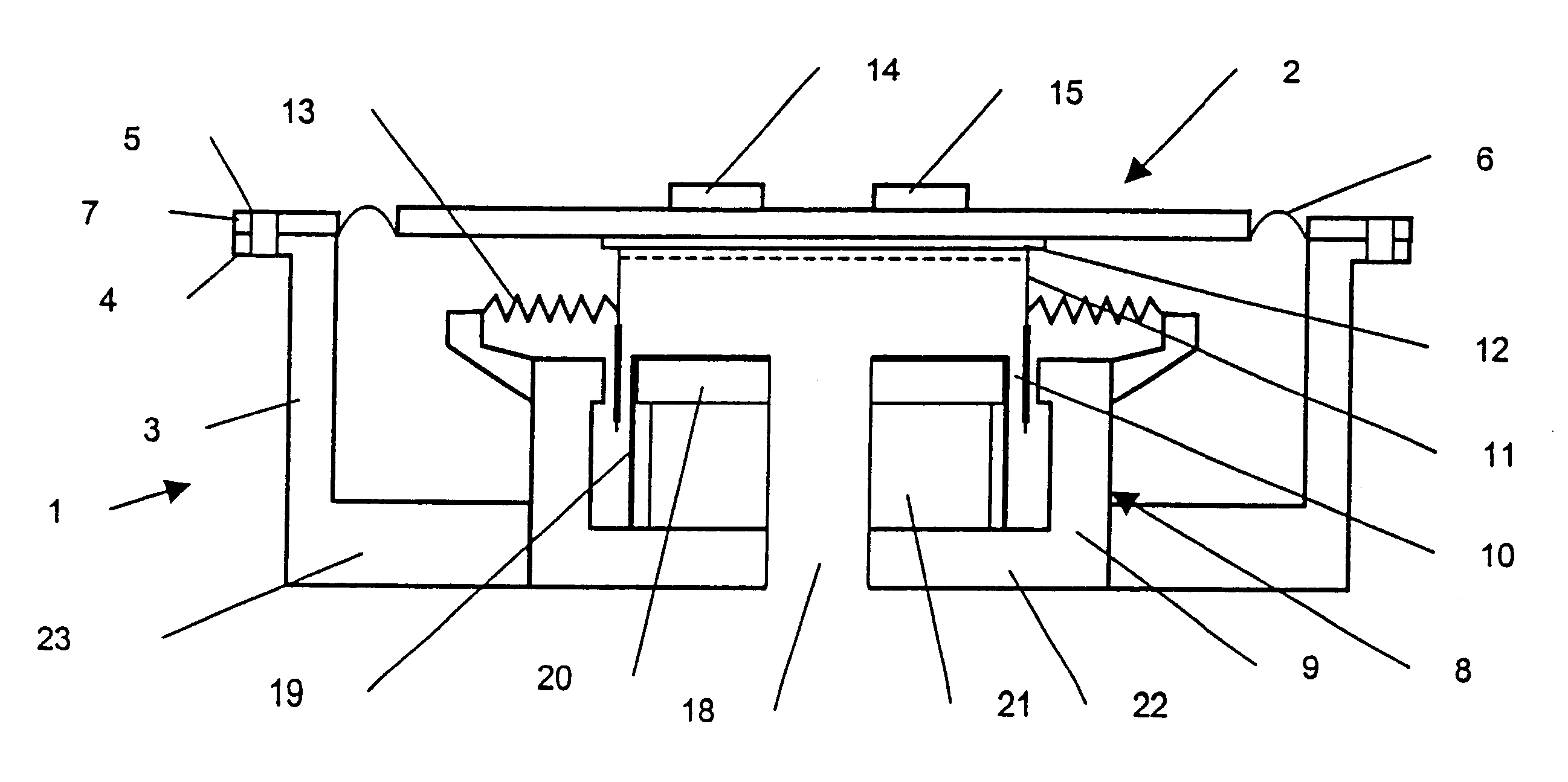

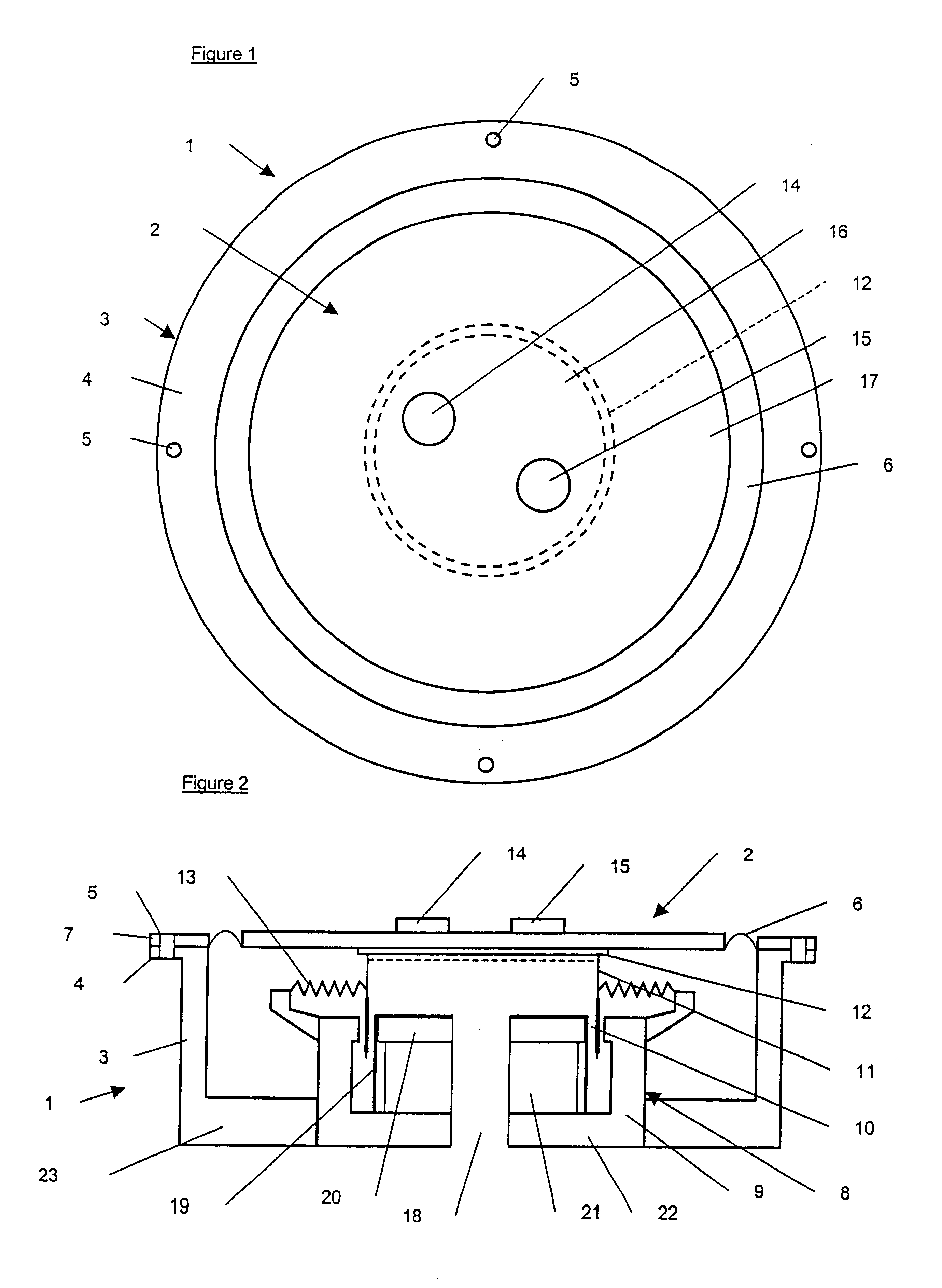

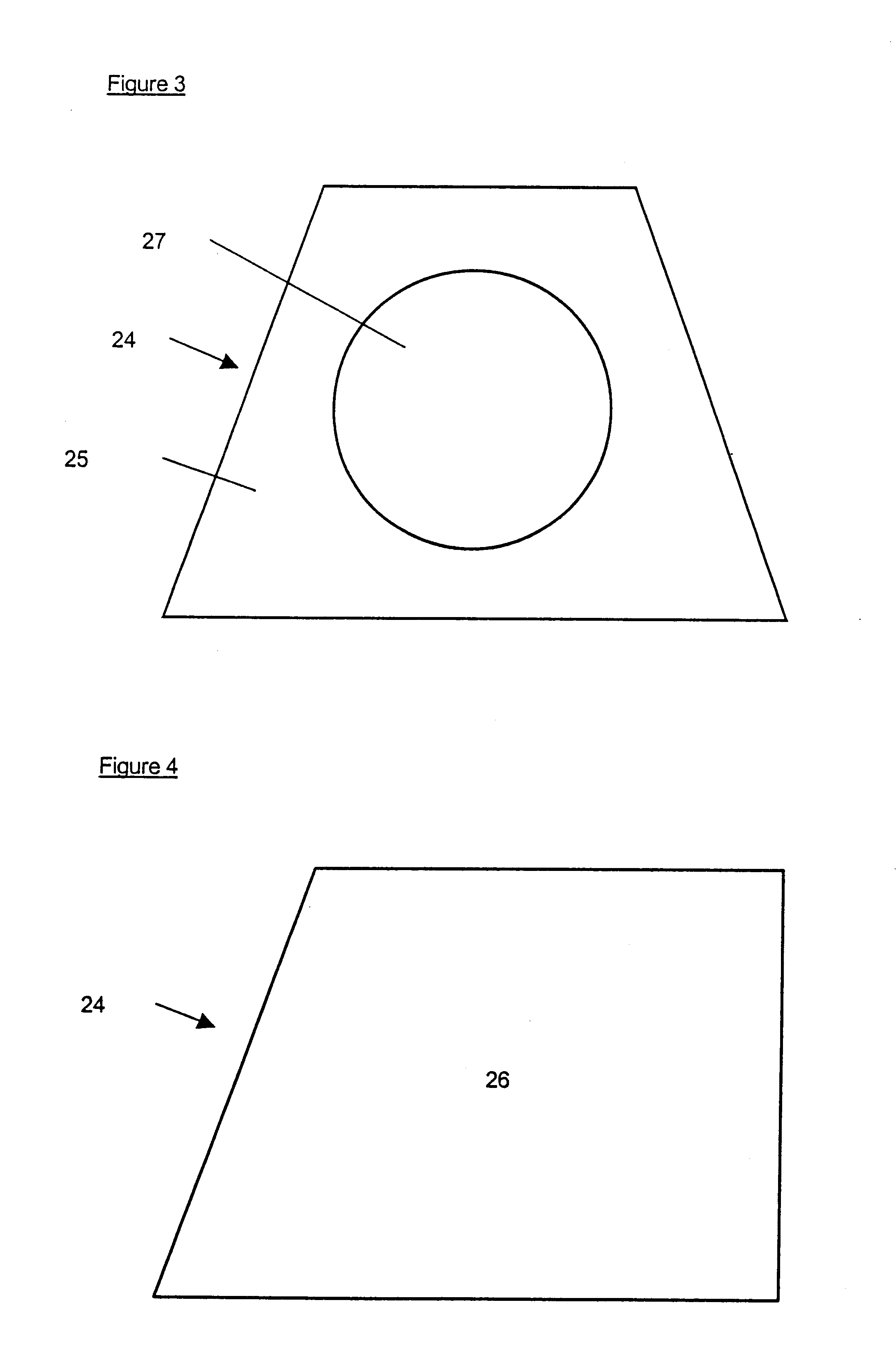

In FIGS. 1 and 2 there is shown a loudspeaker driver motor (1) adapted to be mounted to a baffle, e.g. in an enclosure, see FIGS. 3 and 4 below, comprising a circular flat diaphragm of stiff lightweight material, comprising, for example, a core sandwiched between skins of high tensile sheet material, which forms an acoustic member or radiator adapted to operate both pistonically and by flexure as a bending wave resonant device at higher frequencies. In this way the driver motor of the present invention is able to operate as a full range device covering substantially the whole of the audio spectrum with wide acoustic dispersion, unlike a conventional pistonic driver, whose frequency band or at least its dispersion angle is limited at high frequencies by the diameter of the diaphragm, see FIG. 25 below, and a bending wave driver, which tends to roll-off at frequencies below about 200 Hz, unless of very large diaphragm size.

In generally conventional manner the diaphragm (2) is supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com