High capacitance electrode and methods of producing same

a high capacitance, electrode technology, applied in the direction of electrolytic capacitors, liquid electrolytic capacitors, solid-state diffusion coatings, etc., can solve the problems of large volume, high cost, and inability to fully understand the mechanism of such continued operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

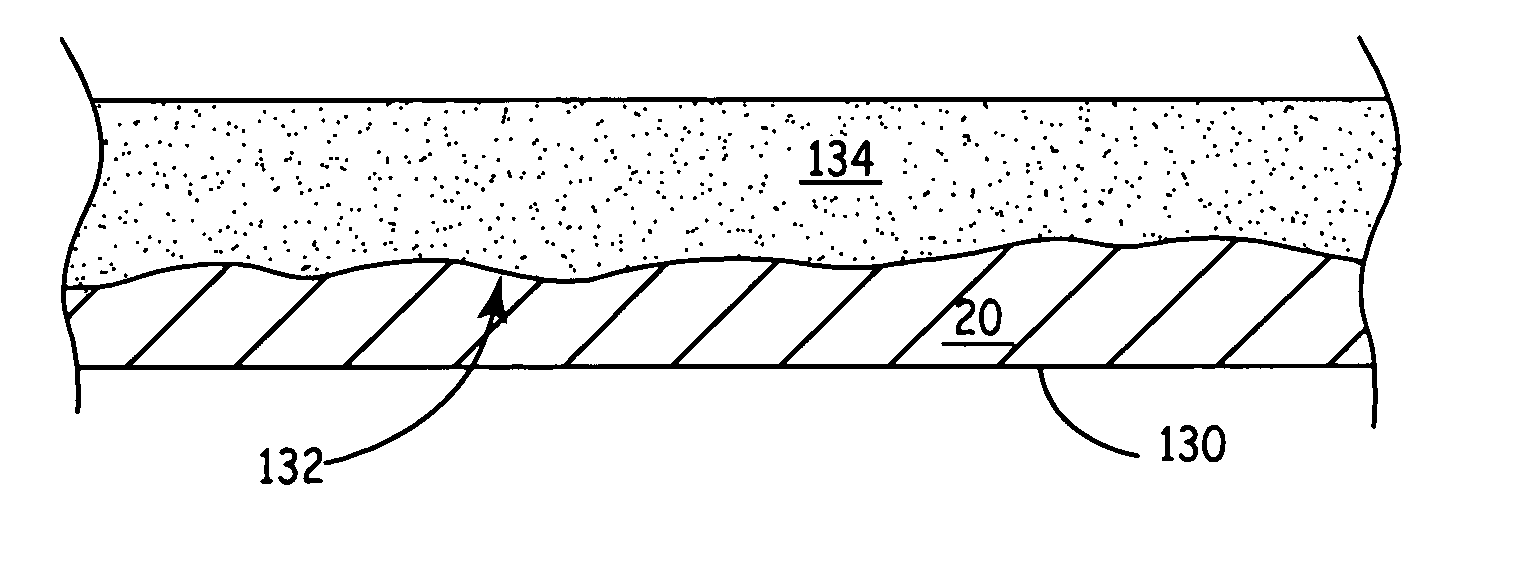

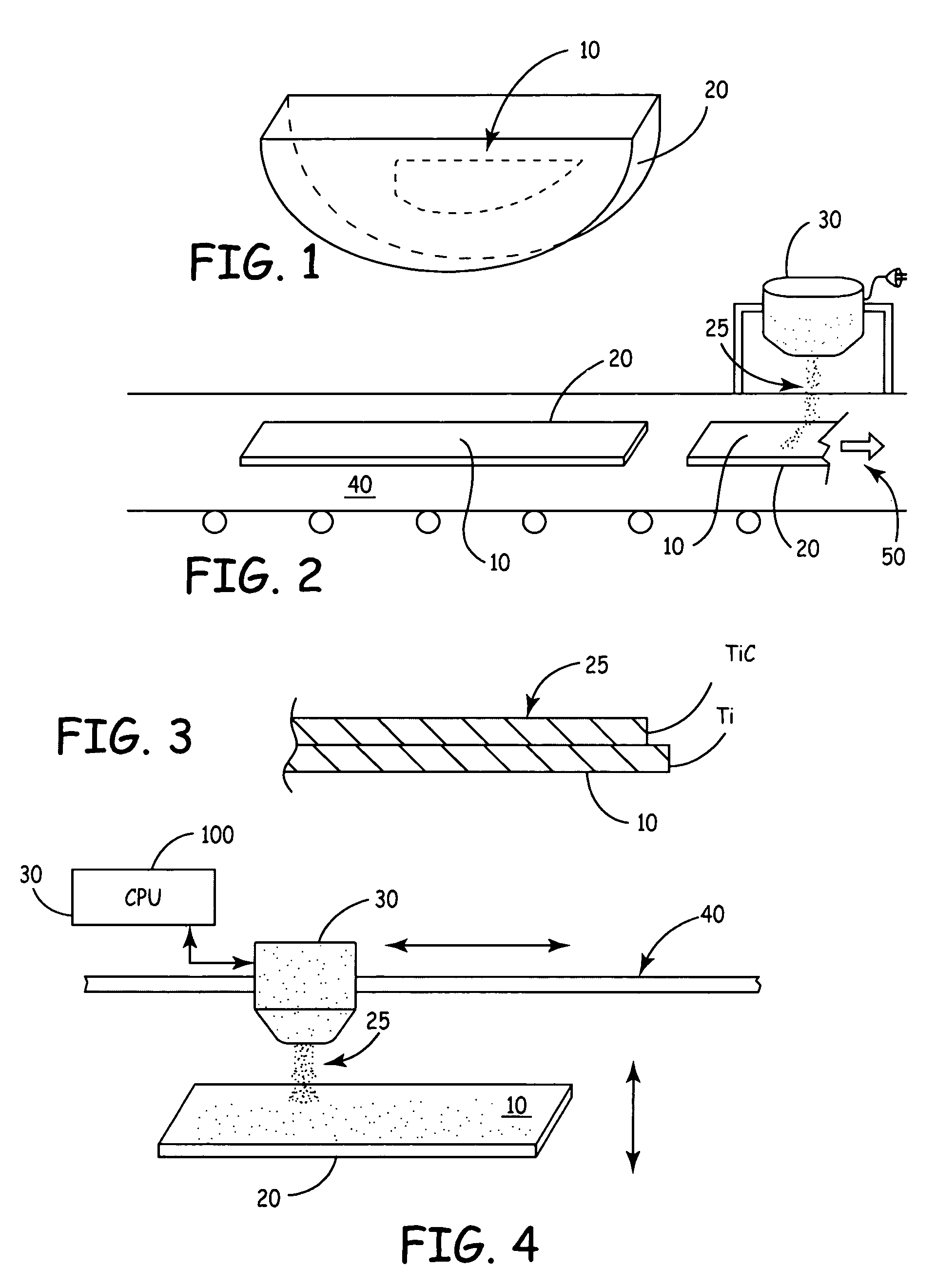

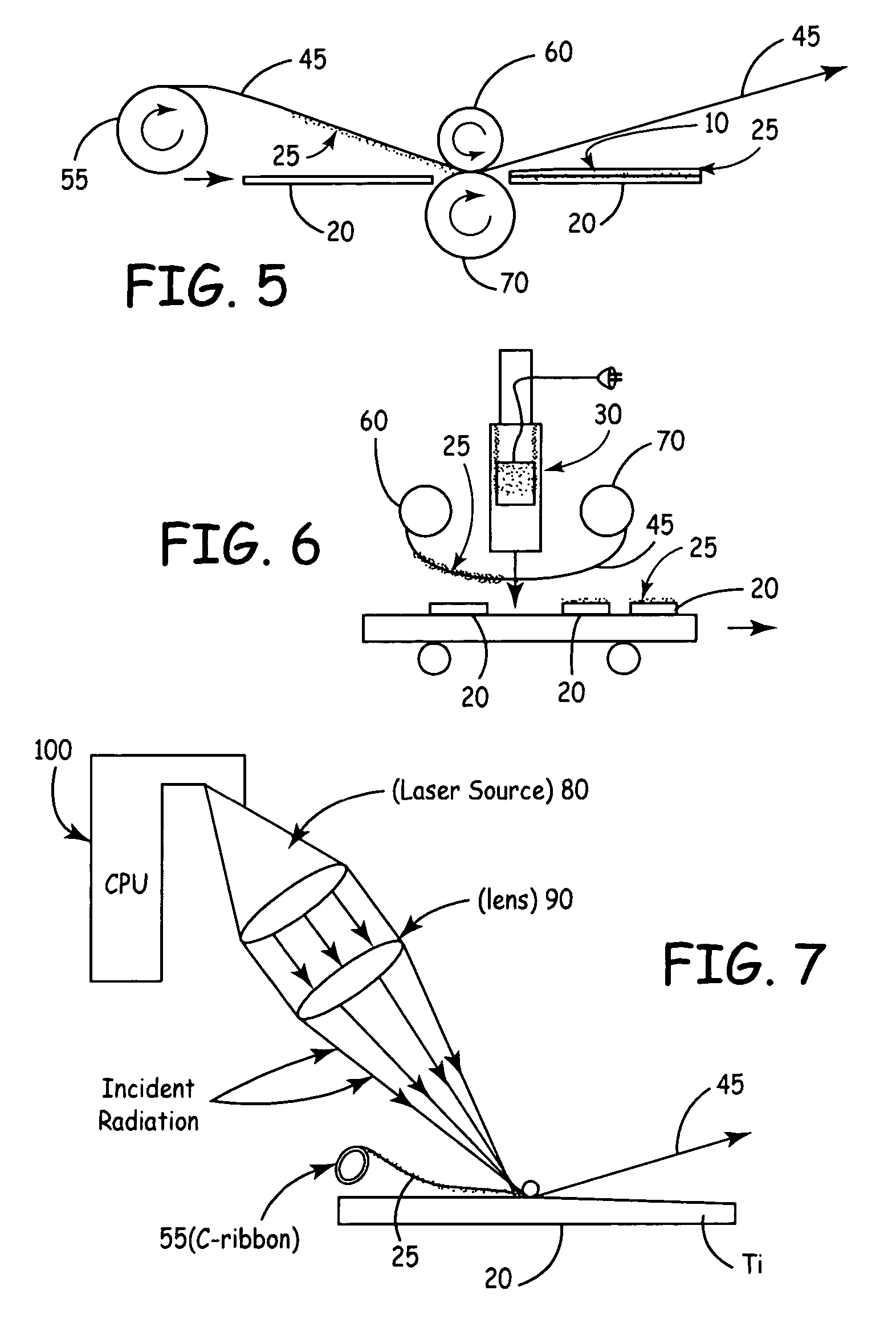

[0024]The present invention provides improved cathodes and methods for producing such cathodes for ultimate use in conjunction with AVM capacitors. The family of cathodes according to the present invention can be produced so that they inhabit a pre-existing metallic surface such as an inner surface of a titanium casing adjacent to but insulated from direct electrical communication from an anode. Foil-type valve metal anodes (such as aluminum) may be used in conjunction with the cathodes of the present invention; however, porous valve metal anodes (formed from metallic powders of tantalum, niobium, etc.) are advantageously employed.

[0025]One exemplary embodiment of the present invention involves depositing a layer of carbon onto an inner surface of a capacitor casing. The inner surface comprises titanium and may include a portion of the casing itself or one or more discrete titanium plates disposed within said casing.

[0026]For an exemplary cathode usable in a wet tantalum capacitor o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumes | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com