Catadioptric objective system and objective system

a catadioptric and objective technology, applied in the field of catadioptric objective systems, can solve the problems of difficult to measure and control the very small distance between the converging point and the storage medium, and the limitation of the reduction of the beam spot by conventional lenses, so as to minimize the fluctuation of the converging point with the thickness change of the adhesive agent, the effect of small thickness and good optical performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

fourth embodiment

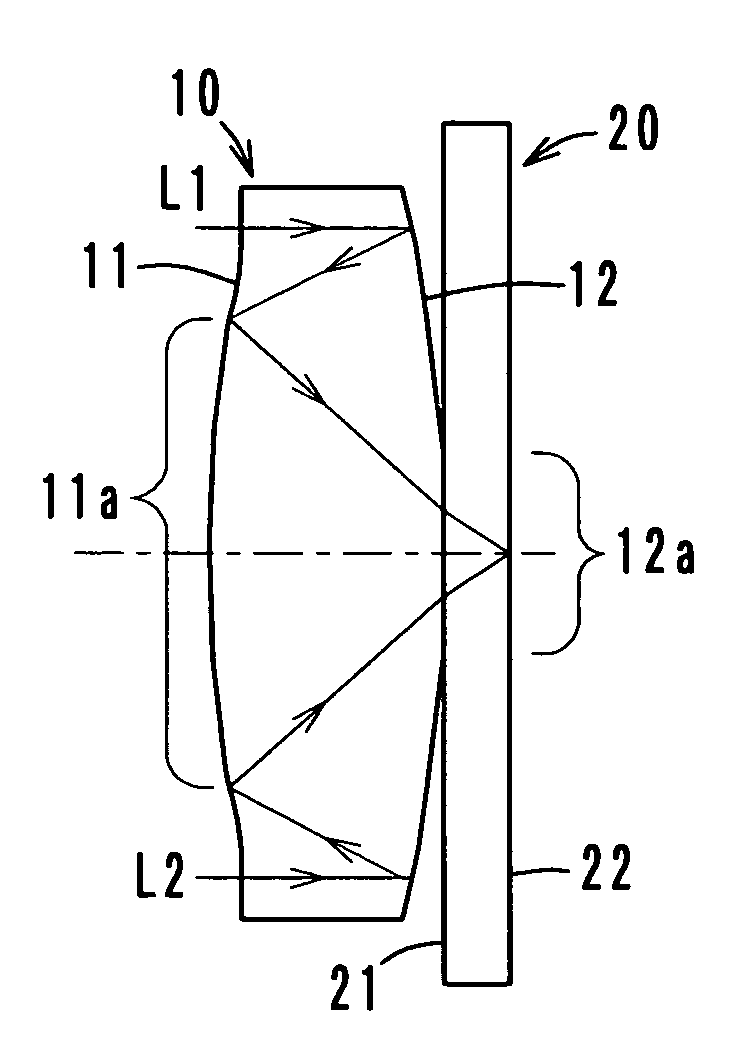

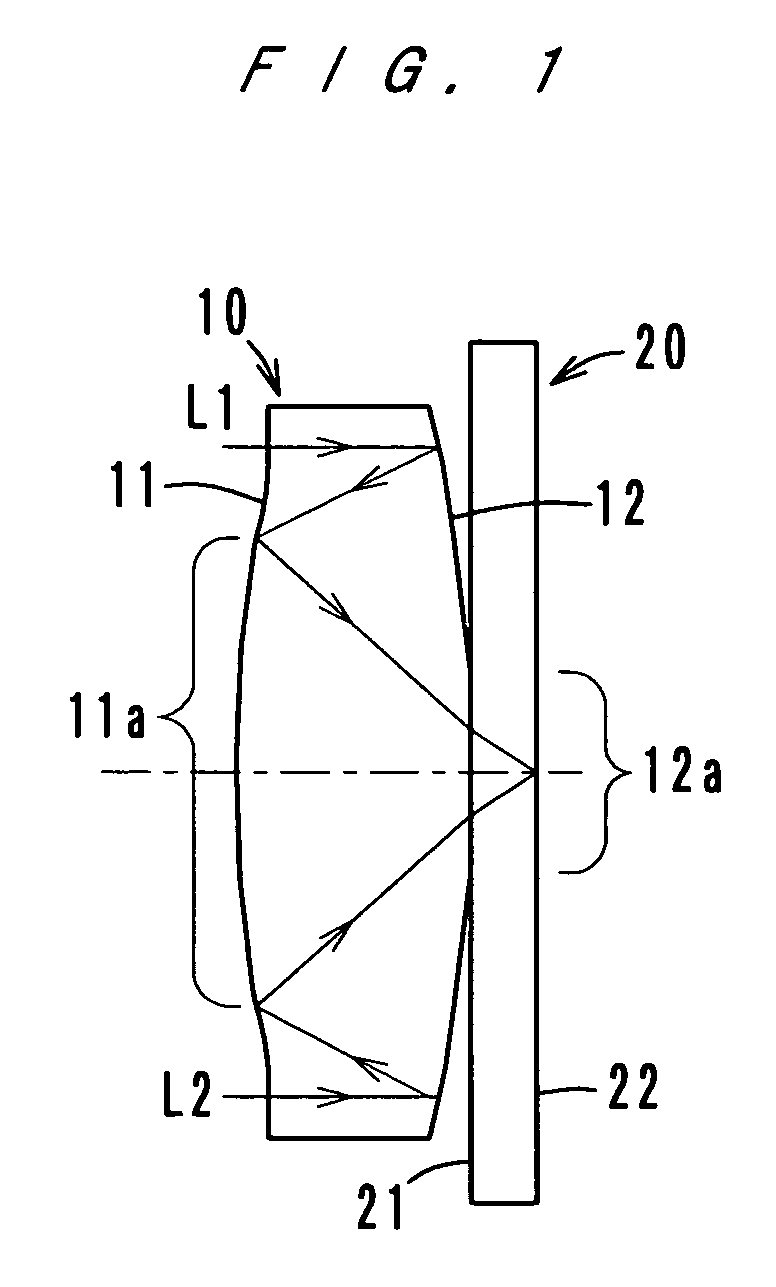

[0034]FIGS. 1, 4, 6 and 8 show the respective structures of catadioptric objective systems according to a first, a second, a third and a FIGS. 2, 5, 7 and 9 show the respective wavefront aberration characteristics of these catadioptric objective systems.

[0035]Each of the catadioptric objective systems according to the first through fourth embodiments comprises a catadioptric objective lens 10 and a light transmitting plate 20. The catadioptric objective lens 10 has a first surface 11 and a second surface 12. The first surface 11 has a positive optical power and transmits incident rays. The second surface 12 has a positive optical power and reflects the incident rays. The second surface 12 has a plane portion 12a in the center.

[0036]The light transmitting plate 20 has a third surface 21 and a fourth surface 22 which are substantially parallel to each other, and the third surface 21 is bonded to the second surface 12 of the catadioptric objective lens 10.

[0037]In FIGS. 1, 4, 6 and 8,...

first embodiment

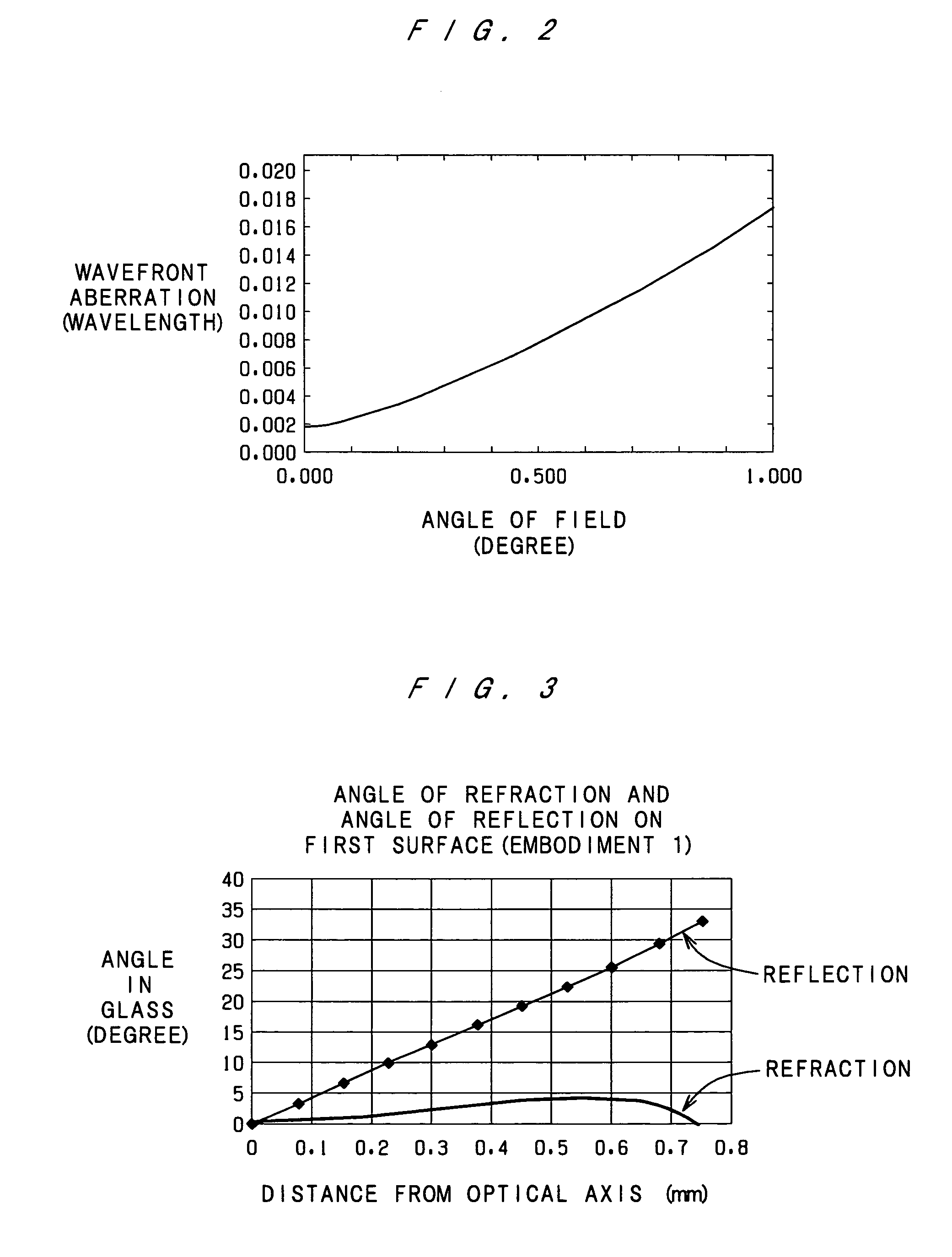

[0086]FIG. 3 is a graph which shows the angle of refraction of incident rays performed by the first surface 11 of the objective lens 10 and the angle of reflection of the rays which enter into the first surface 11 again after being reflected by the second surface 12 (=incident angle) in the The axis of abscissas indicates the distance (mm) from the optical axis of the catadioptric objective lens 10, and the axis of ordinates indicates the angle (degree). The angle of refraction of a ray incident to a point on the first surface 11 of the objective lens 10 is different from the angle of reflection of a ray incident to the same point on the first surface 11, and the characteristic (transmission / reflection) of the coating of the third kind is determined from the difference.

[0087]The dielectric multilayer coating may be, for example, a 40-layer coating shown by Table 7. In Table 7, the material with a refractive index of 2.2 is TiO2, and the material with a refractive index of 1.5 is Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com